Cast aluminum silicon magnesium gas water heater with pneumatic electric coupling ultimate condensation

A gas-fired water heater and cast aluminum technology, which is applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of reduced thermal efficiency, less heat recovery from flue gas latent heat, and worsened heat transfer. Effects of corrosion, heat and mass transfer enhancement, and heat and mass transfer enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

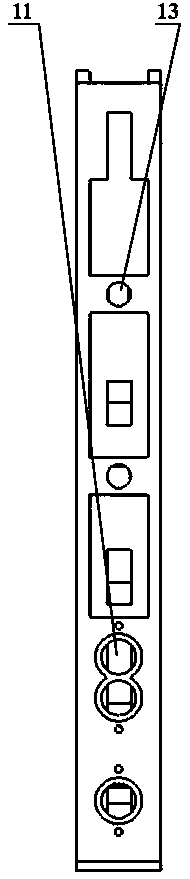

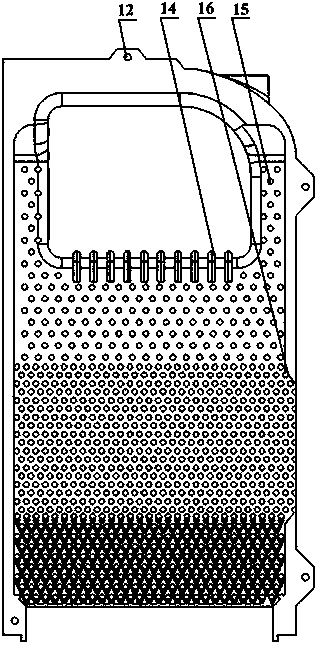

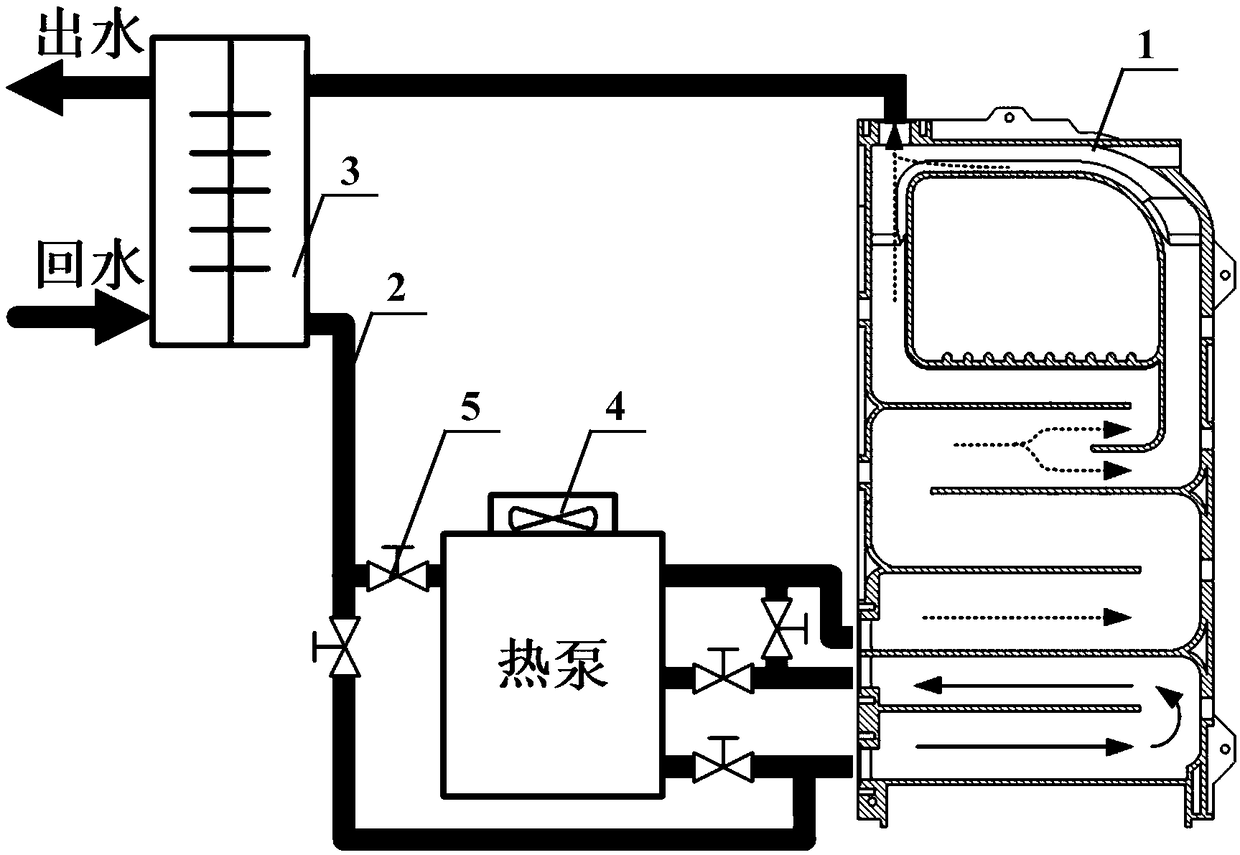

[0036] Such as Figure 2a , Figure 2b , Figure 2c , the modular heat exchange furnace 1 includes an inlet and outlet fluid interface 11, a fixed ear 12 and a molding sand hole 13 located on the side of the modular heat exchange furnace 1, and the tail of the radiation heating area of the modular heat exchange furnace 1 has a guide Flow ribs 14, combined pin fins 15 are regularly arranged on the convection heat exchange surface of the modular heat exchange furnace 1, and a soot cleaning port 16 is opened on one side of the modular heat exchange furnace 1, and the inside of the modular heat exchange furnace 1 It includes an upper waterway 171 and a lower waterway 172 .

[0037] The thickness of the heat exchange area of the modularized heat exchange furnace sheet 1 is 5-7mm. In order to save material and ensure the structural strength, the designed wall thickness of the non-heat exchange area is 8-30mm.

[0038] Such as Figure 2b As shown, the inlet and outlet fluid i...

Embodiment example 2

[0046] In this embodiment, the same symbols are assigned to the same structures as those in Embodiment 1, and the same descriptions are omitted.

[0047] The wall thickness of the modular heat exchange furnace sheet 1 is relatively thin, and the groove is difficult to cast, such as Figure 2e As shown, the diamond-shaped boss design can be adopted, and the height of the diamond-shaped boss is 5-10 mm. By increasing the diamond-shaped convective heat exchange surface, the wall surface of the modular heat exchange furnace 1 is relatively formed to form a "groove" to guide the condensate.

Embodiment example 3

[0049] In this embodiment, the same symbols are assigned to the same structures as those in Embodiment 1, and the same descriptions are omitted.

[0050] The convective heat transfer concentrated area of the modularized heat transfer furnace 1 is staggered with circular pin-fins such as Figure 4 The reinforcement rib connection with a thickness of 2-4mm and a height of 5-15mm can effectively strengthen the strength of the pin-fin structure and reduce the difficulty of drafting while increasing the convective heat transfer area and playing the role of flue gas diversion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com