Preparation method for sample applicable to EBSD analysis of Al and Al alloy

A technology of Al alloy and samples, which is applied in the direction of analyzing materials, using wave/particle radiation for material analysis, measuring devices, etc., can solve the problems of expensive consumables, low popularity, and high price, and achieve high equipment popularity and polishing Effects with a wide range and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

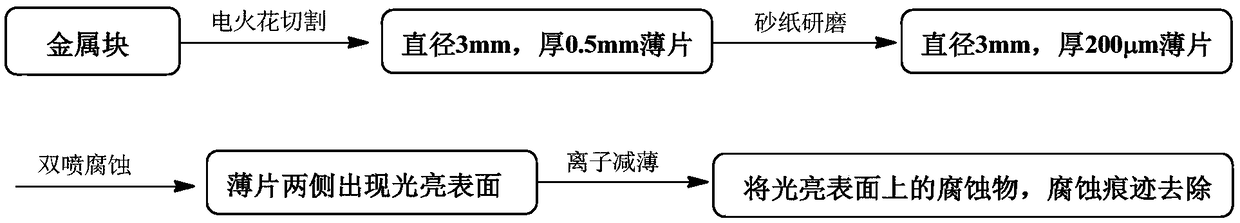

[0039] The flow chart of sample preparation for EBSD analysis is as follows: figure 1 shown.

[0040] Step 1. Use Mo wire as the wire cutting wire, cut a metal sheet with a diameter of 3mm and a thickness of 0.5mm from the pure Al block under the action of cooling liquid at a speed of 0.1mm / min and a current of 2-3A , as the sample to be tested for EBSD.

[0041] Step 2. Use an eraser or a rubber plug to press the metal sheet cut in step 1 and grind it on SiC sandpaper. Use 320#, 800# and 2000# sandpaper in turn to grind the metal sheet from 0.5mm to 200μm. In order to reduce the Stress is introduced during the grinding process, and the use of grinding and polishing machines is not allowed during the grinding process. The manual grinding track should be in the shape of "8".

[0042] Step 3. Configure the double spray liquid, whose composition is 25vol.% nitric acid and 75vol.% methanol; in order to reduce the speed of double spray corrosion, it is necessary to control the re...

Embodiment 2

[0046] Step 1. Use Mo wire as the wire cut wire, at a speed of 0.1mm / min, a current of 2-3A, under the action of cooling liquid, cut a diameter of 3mm and a thickness of 3mm from the hot-extruded pure Al block A metal sheet of 0.5 mm is used as the sample to be tested for EBSD.

[0047] Step 2. Use an eraser or a rubber plug to press the metal sheet cut in step 1 and grind it on SiC sandpaper. Use 320#, 800# and 2000# sandpaper in turn to grind the metal sheet from 0.5mm to 200μm. In order to reduce the Stress is introduced during the grinding process, and the use of grinding and polishing machines is not allowed during the grinding process. The manual grinding track should be in the shape of "8".

[0048] Step 3. Configure double spray liquid, its composition is 25vol.% nitric acid and 75vol.% methanol; in order to reduce the speed of double spray corrosion, it is necessary to control the reaction temperature, so use liquid nitrogen to cool down the double spray liquid, use l...

Embodiment 3

[0052] Step 1. Use Mo wire as the wire cut wire, with a speed of 0.1mm / min, a current of 2-3A, and under the action of cooling liquid, cut a diameter of 3mm from the Al-4.5wt.%Cu alloy block A metal sheet of 0.5 mm is used as the sample to be tested for EBSD.

[0053] Step 2. Use an eraser or a rubber plug to press the metal sheet cut in step 1 and grind it on SiC sandpaper. Use 320#, 800# and 2000# sandpaper in turn to grind the metal sheet from 0.5mm to 200μm. In order to reduce the Stress is introduced during the grinding process, and the use of grinding and polishing machines is not allowed during the grinding process. The manual grinding track should be in the shape of "8".

[0054] Step 3. Configure double spray liquid, its composition is 25vol.% nitric acid and 75vol.% methanol; in order to reduce the speed of double spray corrosion, it is necessary to control the reaction temperature, so use liquid nitrogen to cool down the double spray liquid, use liquid nitrogen to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com