Producing and processing technology of pickled pepper

A processing technology, a technology of soaking peppers, which is applied in the field of production and processing of pickled peppers, can solve the problems of single taste, heavy spicy taste, etc., and achieve the effect of increasing different tastes, improving taste, and improving shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

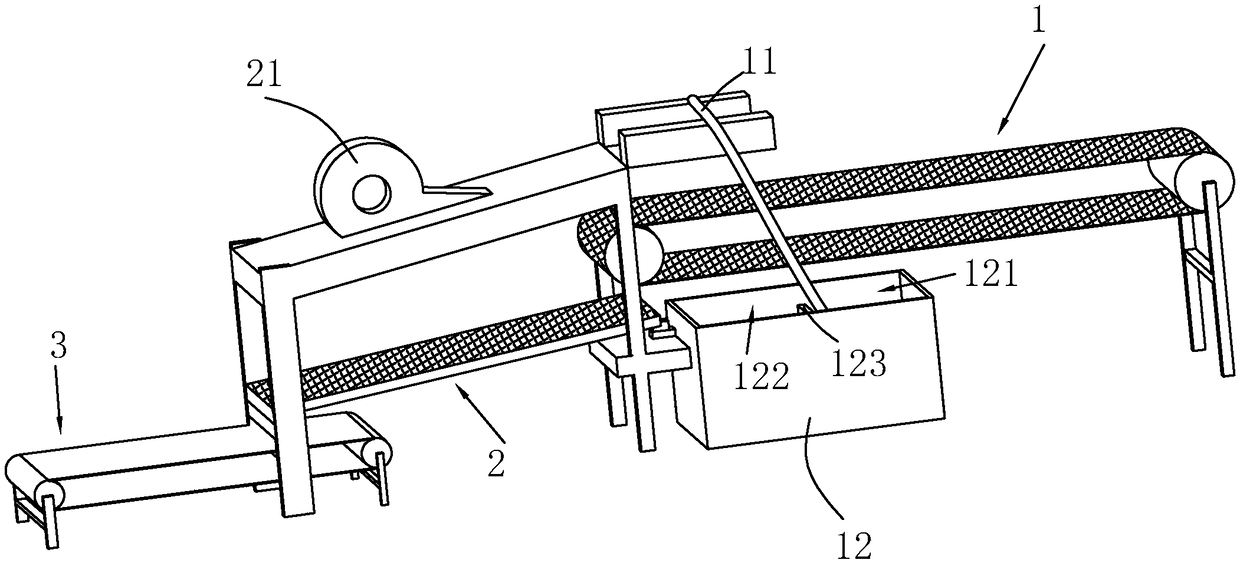

Method used

Image

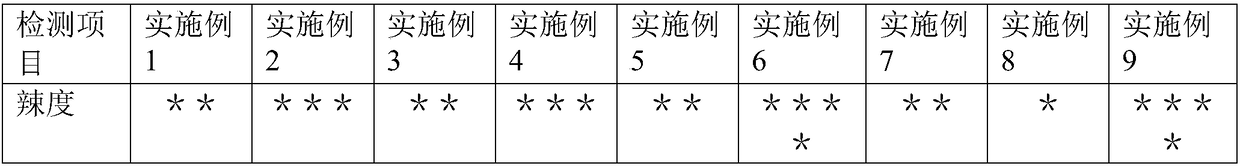

Examples

Embodiment 1

[0048] A production and processing technology for soaked peppers, including the following preparation steps:

[0049] Step 1: Prepare 10kg of ripe fresh chili, cut the handle, wash, drain after washing, and set aside;

[0050] Step 2: Put the peppers from step 1 into the pickle pool, add 10kg of salt water with a mass fraction of 20%, seal the pickle pool, and ferment for 20 days at room temperature; among them, the peppers are put into the pickled pepper pool with the tip Puncture 1mm holes in the pepper;

[0051] Step 3: After the fermentation is finished, clean it with a washing machine;

[0052] Step 4: After cleaning, select the brewed peppers and pack them into bags in the packaging area, and fill the bag with raw material water, and then vacuum seal the packaging bag. Specifically, the weight of the added raw material water and the peppers 250g respectively;

[0053] Step 5: Rinse the water outside the packaging bag with clean water, and then air-dry the water on the packaging ...

Embodiment 2

[0068] A production and processing technology for soaked peppers, including the following preparation steps:

[0069] Step 1: Prepare 10kg of ripe fresh spicy food, cut the handle, wash, drain after washing, and set aside;

[0070] Step 2: Put the pepper from step 1 into the pickle pool, add 10kg salt water with a mass fraction of 20%, then seal the pickle pool, and ferment for 20 days at room temperature; among them, the pepper is put into the pickle pool before using the tip Puncture 2mm holes in the pepper;

[0071] Step 3: After the fermentation, put the soaked pepper into 1% edible alkaline water, stir for 5 minutes, and then clean it with a washing machine;

[0072] Step 4: After cleaning, select the brewed peppers and pack them into bags in the packaging area, and fill the bag with raw material water, and then vacuum seal the packaging bag. Specifically, the weight of the added raw material water and the peppers 250g respectively;;

[0073] Step 5: Rinse the water outside the p...

Embodiment 3

[0084] A production and processing technology for soaked peppers, including the following preparation steps:

[0085] Step 1: Prepare 10kg of ripe fresh chili, cut the handle, wash, drain after washing, and set aside;

[0086] Step 2: Put the pepper from step 1 into the pickle pool, add 10kg of salt water with a mass fraction of 20%, seal the pickle pool, and ferment for 21 days at room temperature; among them, the pepper is put into the pickle pool before using the tip Puncture 1mm holes in the pepper;

[0087] Step 3: After the fermentation is finished, clean it with a washing machine;

[0088] Step 4: After cleaning, select the brewed peppers and pack them into bags in the packaging area, and fill the bag with raw material water, and then vacuum seal the packaging bag. Specifically, the weight of the added raw material water and the peppers 250g respectively;

[0089] Step 5: Rinse the water outside the packaging bag with clean water, and then air-dry the water on the packaging bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com