A kind of fluorinated nano-diamond material and its preparation method and application

A nano-diamond and fluorinated nano-technology, applied in chemical instruments and methods, catalysts, organic chemistry, etc., can solve problems such as being neither environmentally friendly nor safe, and achieve the effect of intact crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

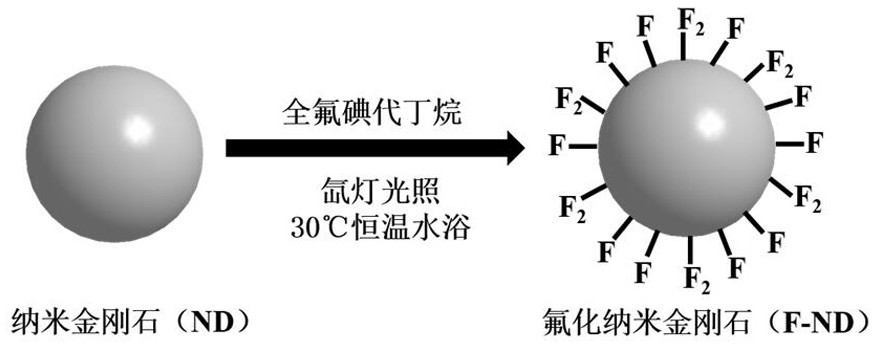

Embodiment 1

[0023] Take 40 mg of nanodiamonds in a 25 mL round bottom flask with a magnet, and add 3 mL of perfluoroiodobutane. Place in a constant temperature water bath at 30°C under magnetic stirring, and illuminate with a xenon lamp for 1 hour. After the fluorination is completed, centrifuge, wash, and dry overnight at 80° C. to obtain fluorinated nano-diamonds, wherein the doping amount of fluorine is 0.1 wt%.

Embodiment 2

[0025] Take 40 mg of nanodiamonds in a 25 mL round bottom flask with a magnet, and add 3 mL of perfluoroiodobutane. Place in a constant temperature water bath at 30°C under magnetic stirring, and illuminate with a xenon lamp for 3 hours. After the fluorination is completed, centrifuge, wash, and dry overnight at 80° C. to obtain fluorinated nano-diamonds, wherein the doping amount of fluorine is 0.3 wt%.

Embodiment 3

[0027]Take 80 mg of nanodiamonds in a 25 mL round bottom flask with a magnet, and add 3 mL of perfluoroiodobutane. Place in a constant temperature water bath at 30°C under magnetic stirring, and illuminate with a xenon lamp for 5 hours. After the fluorination is completed, centrifuge, wash, and dry overnight at 80° C. to obtain fluorinated nano-diamonds, wherein the doping amount of fluorine is 0.5 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com