Process for producing dry pressed porcelain products

A technology for dry-pressed porcelain and porcelain products, applied in the field of dry-pressed porcelain products, can solve the problems of low wear resistance, easy peeling of the pigment layer, and easy fading for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

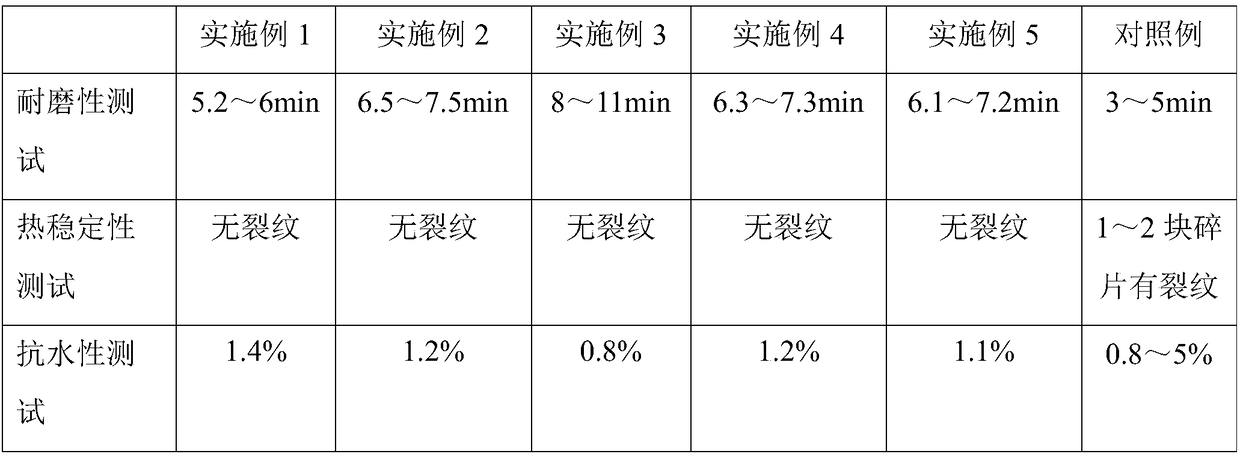

Examples

Embodiment 1

[0021] The present embodiment provides a kind of technique of making dry-pressed porcelain product, comprises the following steps:

[0022] Step 1: Mix 80 parts by weight of magnesium oxide and 10 parts by weight of sodium silicate, then add ethanol 0.7 times its total weight, then grind at a speed of 120r / min for 30 minutes, and then dry it at 50°C to obtain Blank, adjust the moisture content of the blank to 3%, then obtain the blank after shaping under the pressure condition of 620MPa;

[0023] Step 2: Add 15 times of water to 3 parts by weight of guar gum, stir at a speed of 180r / min for 30 minutes, add 8 parts of water-based polyurethane resin, 20 parts by weight of gypsum, 15 parts of gypsum successively during the stirring process Parts by weight of pyrophyllite powder, 15 parts by weight of rutile titanium dioxide, 10 parts by weight of coloring agent, 3 parts of sodium silicate, and 3 parts of auxiliary materials are stirred to obtain pigments, wherein the coloring age...

Embodiment 2

[0026] Step 1: Mix 85 parts by weight of magnesium oxide and 10 parts by weight of sodium silicate, then add ethanol 0.8 times its total weight, then grind at a speed of 125r / min for 40 minutes, and then dry it at 52°C to obtain Blank, adjust the moisture content of the blank to 3%, then obtain the blank after shaping under the pressure condition of 650MPa;

[0027] Step 2: add water that accounts for 17 times of its weight to the guar gum of 3 parts by weight, stir 30 minutes with the speed of 190r / min, add the water-based polyurethane resin of 8 parts, the gypsum of 22 parts by weight, 17 parts successively in the stirring process Parts by weight of pyrophyllite powder, 15 parts by weight of rutile titanium dioxide, 12 parts by weight of coloring agent, 4 parts of sodium silicate, and 5 parts of auxiliary materials are stirred to obtain pigments, wherein the coloring agent is commercially available The non-toxic toner available on the Internet, the auxiliary materials are re...

Embodiment 3

[0030] Step 1: Mix 85 parts by weight of magnesium oxide and 11 parts by weight of sodium silicate, then add ethanol that accounts for 1 times its total weight, then grind at a speed of 130r / min for 45 minutes, and then dry it at 55°C to obtain Blank, adjust the moisture content of the blank to 4%, then obtain the blank after shaping under the pressure condition of 750MPa;

[0031] Step 2: add water that accounts for 17 times of its weight in the guar gum of 4 parts by weight, stir 35 minutes with the speed of 200r / min, add the waterborne polyurethane resin of 9 parts, the gypsum of 23 parts by weight, 17 parts successively in the stirring process Parts by weight of pyrophyllite powder, 18 parts by weight of rutile titanium dioxide, 13 parts by weight of coloring agent, 4 parts of sodium silicate, and 4 parts of auxiliary materials are stirred to obtain pigments, wherein the coloring agent is commercially available The non-toxic toner available on the Internet, the auxiliary m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com