Preparation method of gypsum-based self-leveling floor material

A technology of gypsum-based and base materials, which is applied in the direction of architecture, building structure, floor, etc. It can solve the problems of no pattern or painted pattern, poor water resistance and wear resistance, and easy cracks, etc., to achieve good decorative effect and water resistance. Improved performance and wear resistance, improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

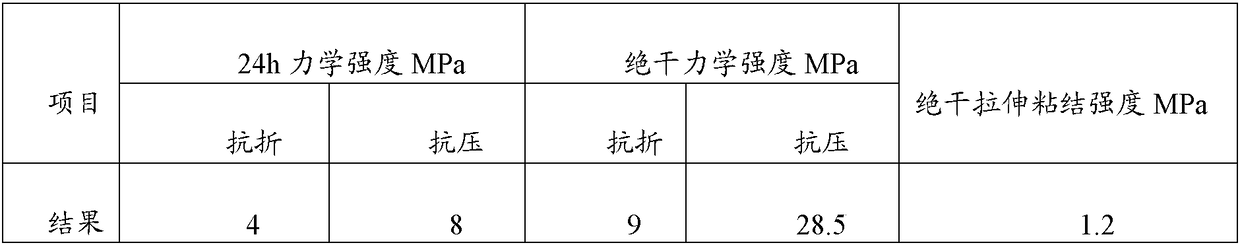

[0042] 1. Prepare α-high-strength gypsum-based materials: weigh 1kg α-high-strength gypsum and 0.03kg red red mud, and mix them evenly; test the standard consistency water consumption, initial setting and final setting time of α-high-strength gypsum-based materials;

[0043] 2. Prepare the first gypsum-based self-leveling floor mortar: weigh 1kg of ordinary gypsum, 0.12kg of Portland cement, 0.002kg of retarder, 0.007kg of water reducing agent, 0.02kg of redispersible latex powder, and 0.0005kg of cellulose Ether, mix well;

[0044] 3. Deploy the second gypsum-based self-leveling floor mortar:

[0045] (1) First, the purchased calcium sulfate whiskers (purchased from Jiangsu Yifu New Material Technology Co., Ltd.) are modified: 1kg of calcium sulfate whiskers are dried at 90-100°C for 5h; The silane coupling agent is mixed in a high-speed mixer for 1 min, so that part of the silane coupling agent is coated on the surface of the calcium sulfate whisker;

[0046] (2) Weigh 1kg o...

Embodiment 2

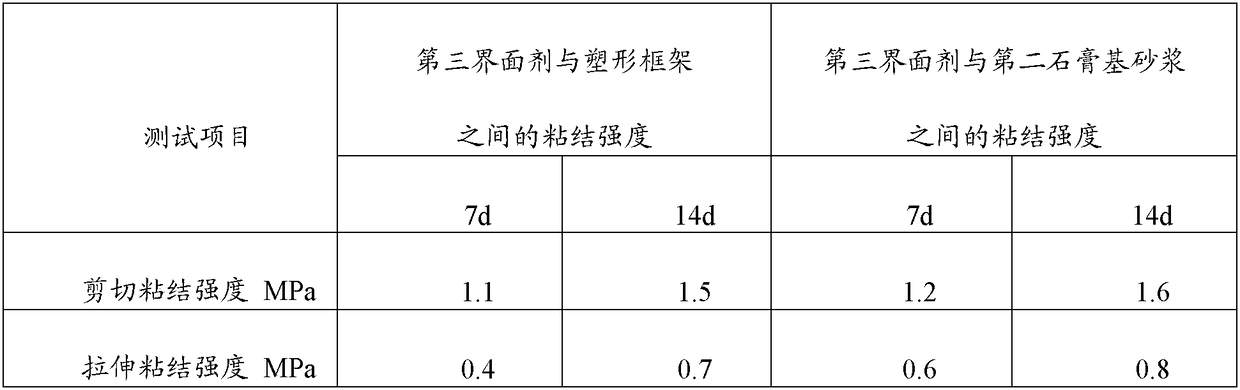

[0061] The only difference between this embodiment and embodiment 1 is that the third interface agent is a self-made interface agent, and when the interface agent is coated on both sides of the shaping frame, roughening treatment is required.

[0062] Steps for homemade interface agent:

[0063] (1) Weigh 0.5kgα high-strength gypsum, 0.5kg ordinary gypsum, 0.03kg Portland cement, 0.03kg sulphoaluminate cement, 0.1kg latex powder, and mix well;

[0064] (2) Weigh 3kg of EL1230S high-strength interface agent, weigh 2kg of mixing water, and mix evenly;

[0065] (3) Mix the premixed powder obtained in step 1 and the liquid obtained in step 2 evenly, and let stand to obtain the interface agent.

Embodiment 3

[0067] The difference between this embodiment and Embodiment 1 is that there is no calcium sulfate whisker in the second gypsum-based self-leveling floor mortar formula.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com