Method for extracting and refining long-chain dicarboxylic acid from fermentation liquor

A long-chain dicarboxylic acid and fermentation broth technology, applied in the separation/purification of carboxylic acid compounds, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of high energy consumption and large loss of dicarboxylic acid , to achieve good product quality, improve solubility, and small crystal particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

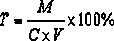

Method used

Image

Examples

Embodiment 1

[0030] (1) Take 0.5m of dodecyl dicarboxylic acid fermentation broth 3 Add to 1m3 In a closed container with stirring, add potassium hydroxide to the fermentation broth to make the pH of the fermentation broth 9, stir at 100rpm, continue to heat up to 90°C, and keep the temperature constant for 20min;

[0031] (2) After the treatment in step (1), filter through a 20 nm membrane filtration device to obtain the fermentation clear liquid into 0.7m 3 In the fermentation clear liquid tank, let it stand at a constant temperature of 80°C for 20 minutes, and remove the aqueous phase clear liquid layer;

[0032] (3) Inject 380L aqueous phase clear liquid layer into 1m 3 In a closed container with stirring and heating, add 100L butyl ether at a temperature of 80°C and a speed of 100rpm, and raise the temperature to 90°C; then add sulfuric acid to control the pH of the system to 5, raise the temperature to 97°C, and increase the speed to 200rpm until the system Medium and long chain di...

Embodiment 2

[0035] (1) Take 0.5m of thirteen carbon dicarboxylic acid fermentation broth 3 join 1 m 3 In a closed container with stirring, add potassium hydroxide to the fermentation broth to make the pH of the fermentation broth to 10, stir at 100 rpm, continue to heat up to 80 ° C, and keep the temperature for 30 minutes;

[0036] (2) After the treatment in step (1), filter through a 40nm membrane filtration device to obtain the fermentation clear liquid into 0.7 m 3 Fermentation clear liquid tank, let it stand at a constant temperature of 90°C for 20 minutes, and remove the aqueous phase clear liquid layer;

[0037] (3) Inject 380L aqueous phase clear liquid layer into 1m 3 In a closed container with stirring and heating, add 80L ethyl acetate at a temperature of 85°C and a speed of 150rpm, and heat up to 90°C; then add sulfuric acid to control the pH of the system to 4, heat up to 97°C, and increase the speed to 200rpm until The long-chain dicarboxylic acid is completely dissolved ...

Embodiment 3

[0040] (1) Take 0.5m of dodecyl dicarboxylic acid fermentation broth 3 Add to 1m 3 In a closed container with stirring, add sodium hydroxide to the fermentation broth to make the pH of the fermentation broth 9.5, stir at 100rpm, continue to heat up to 90°C, and keep the temperature constant for 30min;

[0041] (2) After the treatment in step (1), filter through a 25nm membrane filtration device to obtain the fermentation clear liquid into 0.7m 3 Fermentation clear liquid tank, let it stand at a constant temperature of 80°C for 30 minutes, and remove the phase water phase clear liquid layer;

[0042] (3) Inject 350L aqueous phase clear liquid layer into 1m 3 In a closed container with stirring and heating, add 100L propyl ether at a temperature of 80°C and a speed of 100rpm, and raise the temperature to 85°C; then add sulfuric acid to control the pH of the system to 5, raise the temperature to 97°C, and increase the speed to 200rpm until the system Medium and long chain dica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com