Preparation method of biological fiber and plastic composite material with high insulating property

A biological fiber and composite material technology, applied in the field of composite materials, can solve the problems of complex production process and high production cost, and achieve the effect of simple production process, low production cost and strong toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

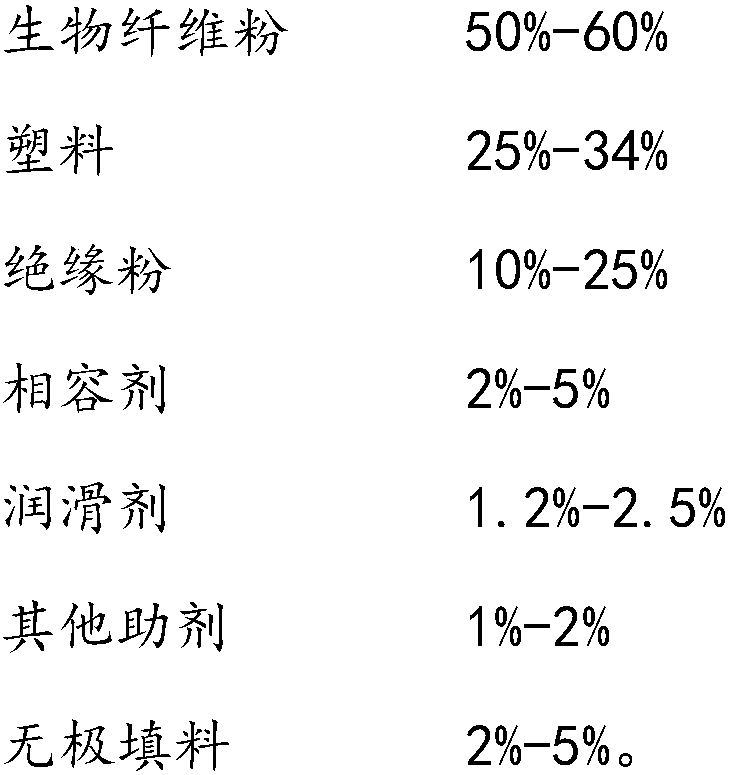

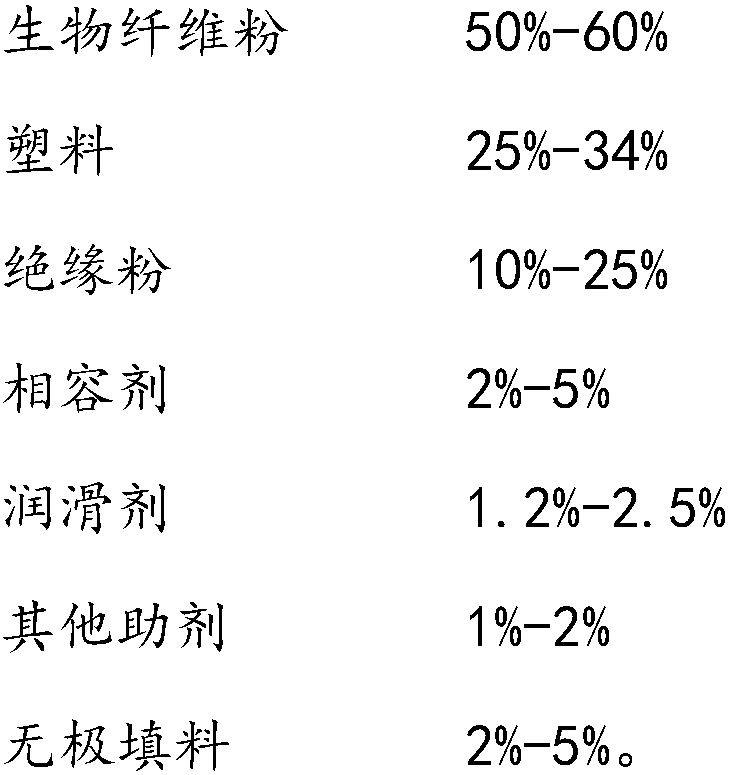

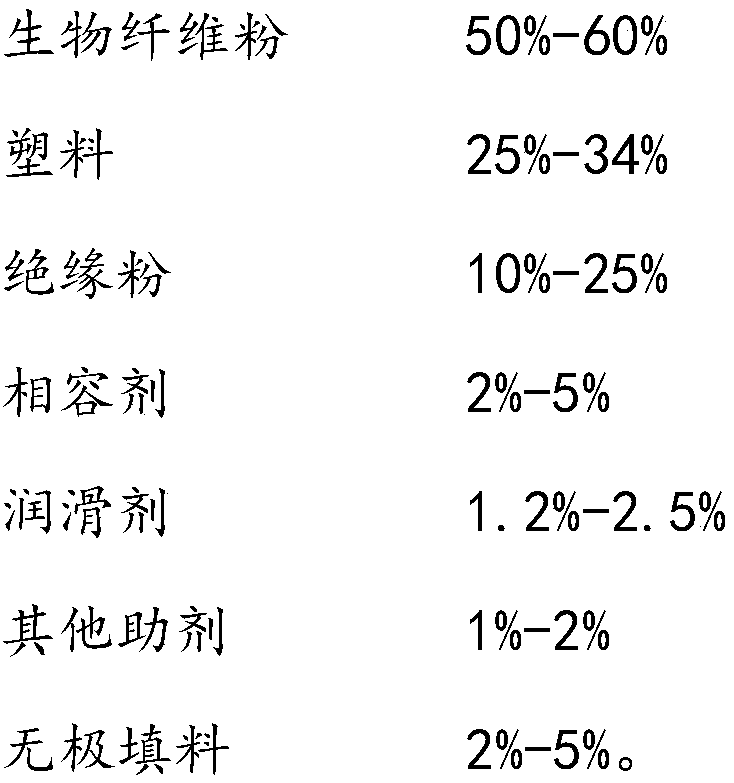

[0029] A method for preparing a biofiber and plastic composite material with high insulating performance, comprising the following raw materials in parts by weight:

[0030]

[0031] The other additives are a mixture of antifungal agent and matting powder with a weight ratio of 1:1, and the nonpolar filler is a mixture of calcium powder and talcum powder with a weight ratio of 1:1.

Embodiment 1

[0033] A preparation method of biological fiber and plastic composite material with high insulation performance, comprising the following raw materials in proportion by weight: 50 parts of biological fiber powder, 30 parts of plastic, 10 parts of insulating powder, 2.5 parts of compatibilizer, and 1.5 parts of lubricant 1 part, 1 part of antifungal agent, 1 part of matting powder, 2 parts of calcium powder and 2 parts of talcum powder. Fiber, silk fiber, plant straw, bamboo powder or reed powder, these raw materials are very common raw materials, cheap, easy to find, the insulating powder is 3M insulating epoxy powder, the insulating effect is good , widely used, the compatibilizer is N,N'-ethylene bisstearamide, N,N'-ethylene bisstearamide slightly yellow fine particles, non-toxic, no side effects on the human body, so Described lubricant is silicone powder, and silicone powder is common lubricant, and described antifungal agent is pentachlorophenol, and pentachlorophenol is ...

Embodiment 2

[0035] A preparation method of a biological fiber and plastic composite material with high insulating performance, comprising the following raw materials in proportion by weight: 55 parts of biological fiber powder, 25 parts of plastic, 10 parts of insulating powder, 2.5 parts of compatibilizer, and 1.5 parts of lubricant 1 part, 1 part of antifungal agent, 1 part of matting powder, 2 parts of calcium powder and 2 parts of talcum powder. Fiber, silk fiber, plant straw, bamboo powder or reed powder, these raw materials are very common raw materials, cheap, easy to find, the insulating powder is 3M insulating epoxy powder, the insulating effect is good , widely used, the compatibilizer is N,N'-ethylene bisstearamide, N,N'-ethylene bisstearamide slightly yellow fine particles, non-toxic, no side effects on the human body, so Described lubricant is silicone powder, and silicone powder is common lubricant, and described antifungal agent is pentachlorophenol, and pentachlorophenol i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com