Water dispersible rein and a preparing method thereof

A technology for dispersing resin and molecular weight, which is applied in the direction of anti-corrosion coatings, etc., can solve problems such as research stays, achieve the effects of reducing pollution, wide sources of raw materials, and reducing hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

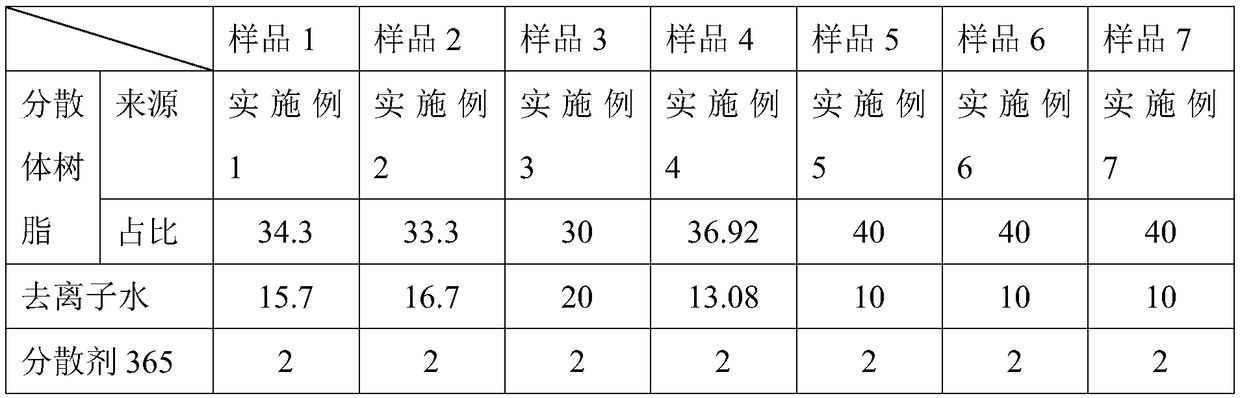

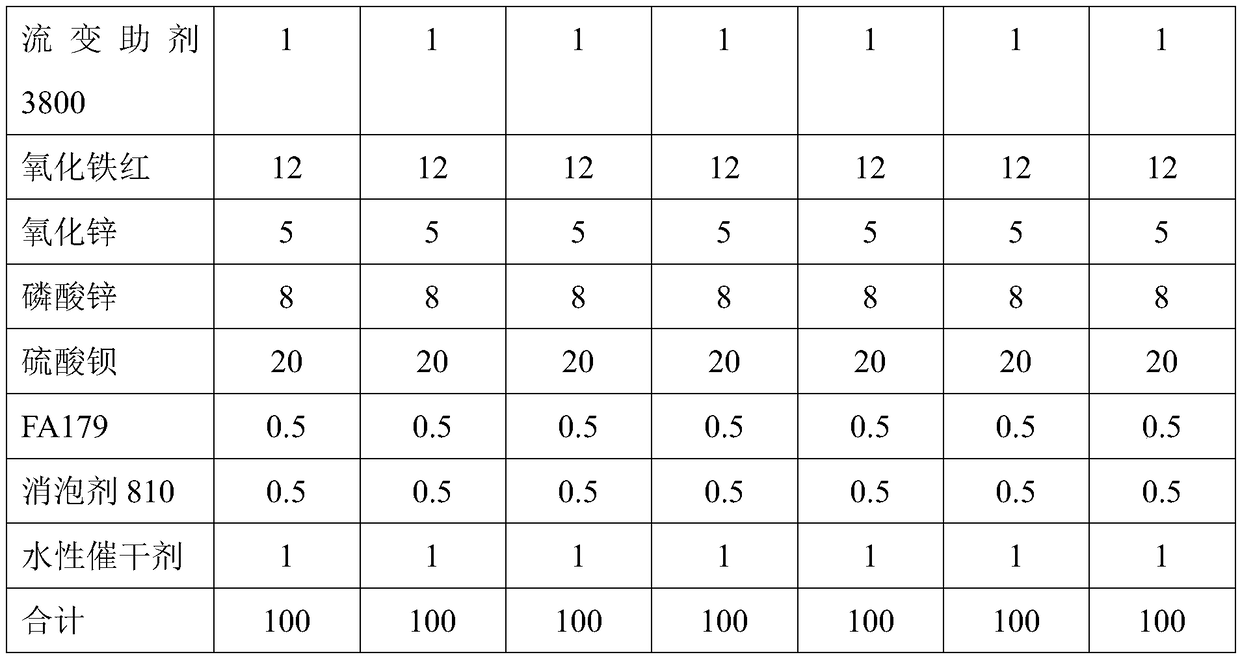

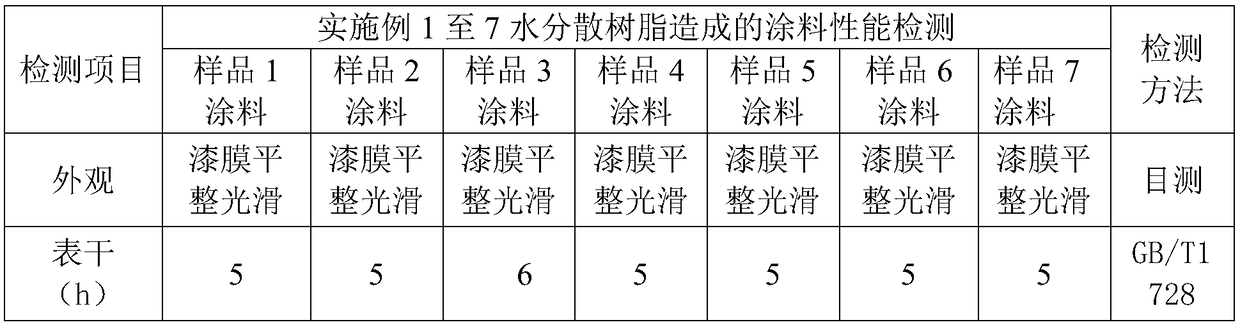

Examples

Embodiment 1

[0021] Add 25 parts of cardanol and 40 parts of epoxidized soybean oil into a 300ml four-necked flask equipped with a stirrer, reflux condenser, and thermometer, pass in nitrogen for protection, start stirring and gradually heat up to 210-215°C to keep warm and react To the acid value below 0.5mg KOH / g; cool down to 45°C, add 3 parts of toluene diisocyanate TDI, keep warm at 45°C for 1 hour, add 2 parts of polyethylene glycol PEG, keep warm at 45°C for 1 hour, and heat up to 85°C React for 1 hour; lower the temperature to 70°C, add 50 parts of deionized water, stir evenly, and cool to room temperature to obtain the product.

Embodiment 2

[0023] Add 30 parts of cardanol and 35 parts of epoxy dehydrated castor oil into a 300ml four-necked flask equipped with a stirrer, reflux condenser, and thermometer, pass in nitrogen for protection, start stirring and gradually heat up to 210-215°C to keep the temperature React until the acid value is below 0.5mg KOH / g; cool down to 40°C, add 2 parts of methylene diphenyl diisocyanate MDI, 2 parts of xylylene diisocyanate XDI, keep warm at 40°C for 2 hours, add polypropylene glycol 3 parts of PPG, keep warm at 40°C for 2 hours, raise the temperature to 70°C for 2 hours; cool down to 60°C, add 48 parts of deionized water, stir evenly, and cool to room temperature to obtain the product.

Embodiment 3

[0025] Add 35 parts of cardanol, 15 parts of epoxy soybean oil, 10 parts of epoxy linseed oil, and 10 parts of epoxy dehydrated castor oil in a 300ml four-neck flask equipped with a stirrer, reflux condenser, and thermometer, and feed nitrogen for protection , start stirring and gradually heat up to 210-215°C, keep warm and react until the acid value is below 0.5mg KOH / g; cool down to 50°C, add 2 parts of toluene diisocyanate TDI, 2 parts of hexamethylene diisocyanate HDI, isofor 2 parts of ketone diisocyanate IPDI, keep warm at 50°C for 0.5 hours, add 4 parts of polytetrahydrofuran PTHF, keep warm at 50°C for 0.5 hours, heat up to 90°C and react for 0.5 hours; cool down to 80°C, add 40 parts of deionized water, stir Evenly, cool to room temperature, that is.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com