Cage structure microporous culture dish for forming three-dimensional microtissue of cells in vitro and preparation method thereof

A culture dish and micro-tissue technology, applied in the field of in vitro three-dimensional culture of biological cells, can solve the problems of cumbersome process, limited biological materials, high price, etc., and achieve the effects of simplifying the preparation process, simple preparation process and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

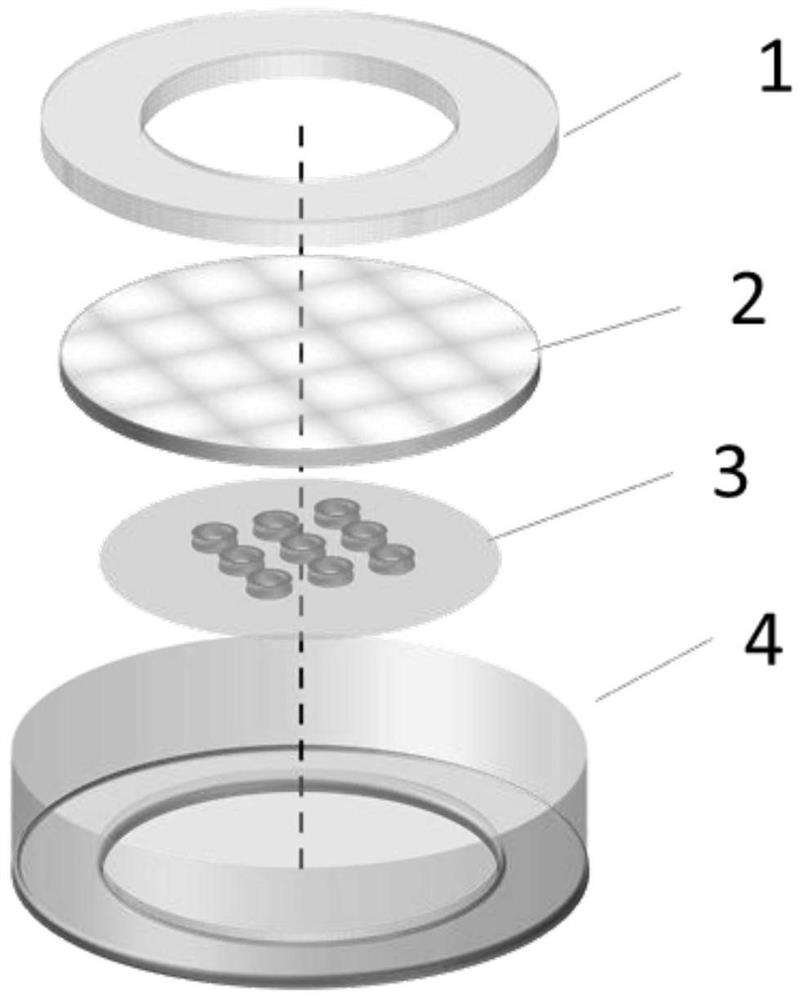

[0043] In this example, see Figure 1 ~ Figure 3 , a cage structure microporous culture dish for forming three-dimensional cell microtissues in vitro, the cage structure microporous culture dish is composed of four basic parts spliced and assembled:

[0044] The first basic part is the petri dish 4 after the bottom surface is modified, that is, the bottom of the petri dish 4 is combined with a biocompatible material film layer to form the inner layer of the petri dish 4 container, and the inner surface of the petri dish 4 is modified, see figure 1 ;

[0045] The second basic part is the modified polymer microwell array component 3, which adopts a biocompatible material film with a hollow micropore array structure, so that the polymer microwell array component 3 has cell growth micropore grooves distributed in an array , the size of the outer edge of the polymer microwell array assembly 3 is smaller than the size of the inner cavity of the container of the petri dish 4, and ...

Embodiment 2

[0064] This embodiment is basically the same as Embodiment 1, especially in that:

[0065] In this example, see Figure 4 , a cage-structured microporous culture dish for forming three-dimensional cell microtissues in vitro and its preparation method are the same as in Example 1.

[0066] Experimental test analysis:

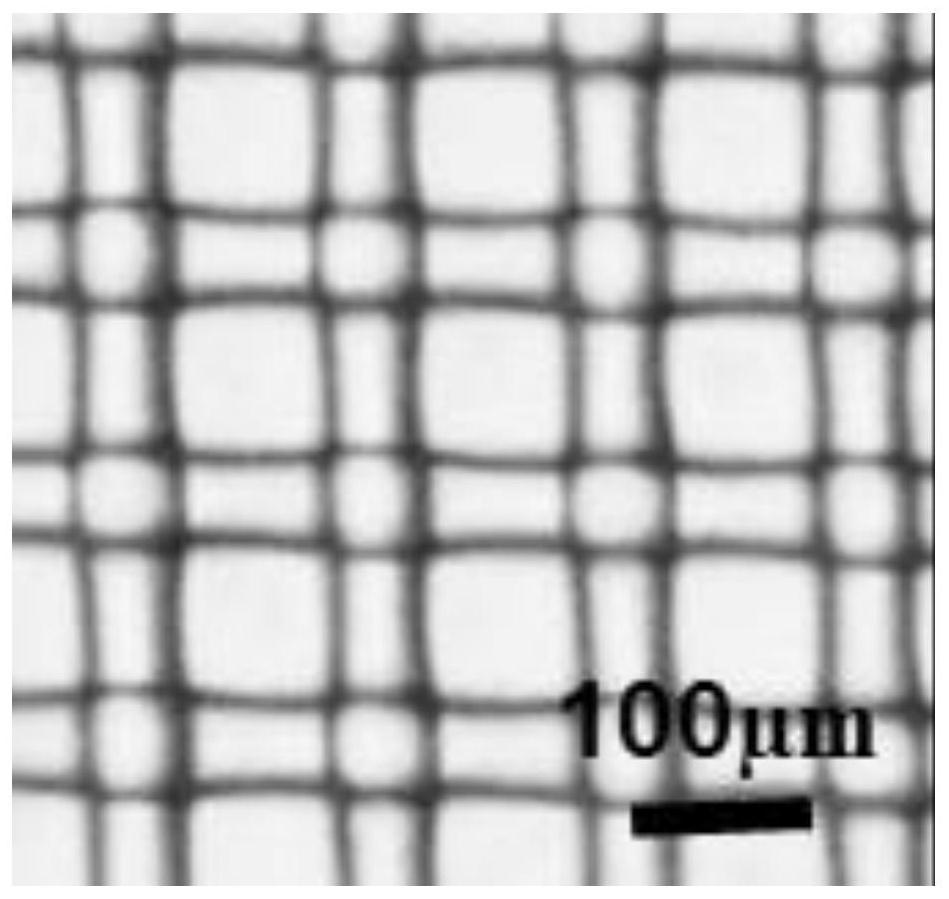

[0067] The cage-structured microporous culture dish used in this embodiment for the formation of three-dimensional cell microtissues in vitro was used to conduct cell culture experiments in vitro. Utilize present embodiment to prepare cage structure microporous culture dish, its cell mesh 2 is the nylon mesh of pore 100 microns, as Figure 4 As indicated, the research on three-dimensional microtissue formation of lung tumor cells in vitro was carried out. In the experiment, 1×10 5 Individual / mL large cell carcinoma NCI-H460 cells in lung non-small cell lung cancer are placed in a cage-structured microwell culture dish, and the cells enter the cage-structured po...

Embodiment 3

[0070] This embodiment is basically the same as the previous embodiment, and the special features are:

[0071] In this example, see Figure 5 , a cage-structured microporous culture dish for forming three-dimensional cell microtissues in vitro and its preparation method are the same as in Example 1.

[0072] Experimental test analysis:

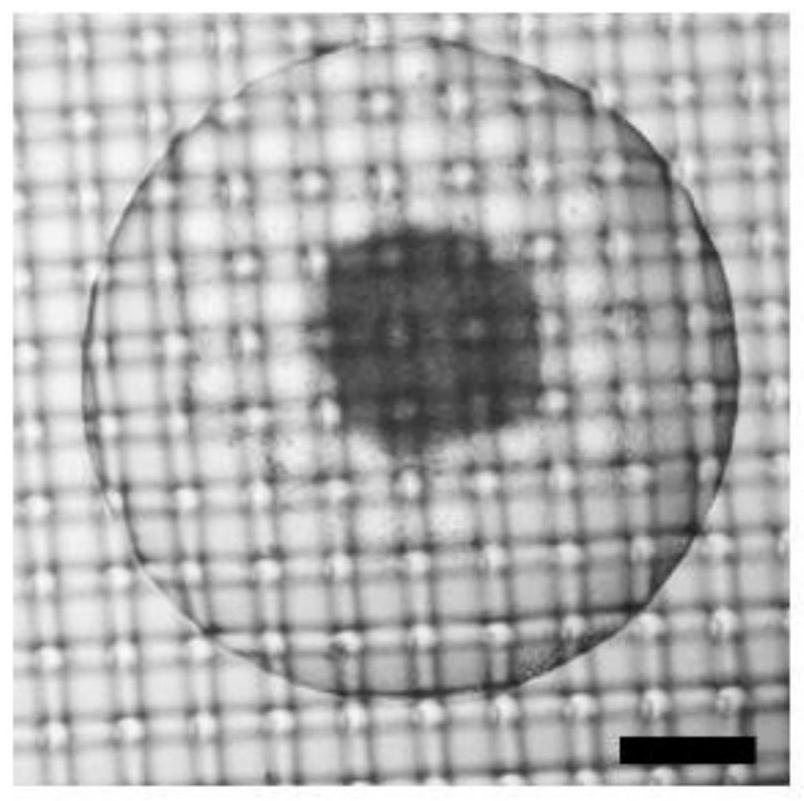

[0073] The cage-structured microporous culture dish used in this embodiment for the formation of three-dimensional cell microtissues in vitro was used to conduct cell culture experiments in vitro. Utilize present embodiment to prepare cage structure microporous culture dish, its cell mesh 2 is the nylon mesh of pore 100 microns, as Figure 5 As shown, a three-dimensional co-culture study of lung tumor cells and vascular endothelial cells was carried out. In the experiment, inoculate 1×10 5 Large cell carcinoma NCI-H460 cells / mL of lung non-small cell lung cancer were cultured in a cage microwell culture dish for 3 days to obtain NCI-H460 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com