Nattokinase drying protective agent

A drying protective agent, nattokinase technology, applied in the direction of enzyme stabilization, hydrolase, etc., can solve the problems of loss of enzyme activity, no research on drying process and enzyme activity stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 The preparation of nattokinase crude enzyme liquid

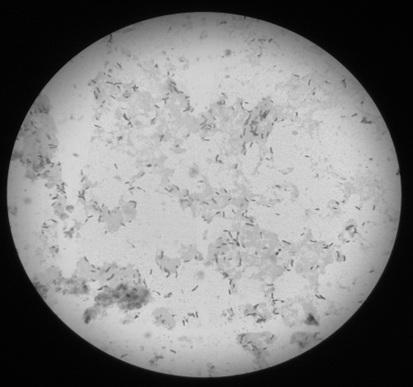

[0023] 1. Activation of strains and preparation of bacterial suspension

[0024] Buy Bacillus natto powder, dissolve it with sterile water, and dilute it to 10 -3 to 10 -6 Different gradient plates were streaked and cultured on LB medium containing 2% agar for 18 hours for microscopic examination. figure 1 , and then pick a single colony into LB liquid medium, activate three generations, then inoculate 3% inoculum in LB liquid medium at 120rpm, and cultivate at 37°C for 12h; the bacterial liquid is placed in a high-speed refrigerated centrifuge at 4°C, 8000r / min centrifuged for 10min; the centrifuged cells were washed twice with sterile water, resuspended, and the concentration of the bacterial suspension was adjusted to 10 7 CFU / mL, as starter culture.

[0025] 2. Fermentation of fresh bean dregs

[0026] Soak the soybeans in distilled water at room temperature for 14 hours, then refine them (soybe...

Embodiment 2

[0029] Embodiment 2 The preparation of nattokinase drying protectant

[0030] Prepare trehalose protective agent, mixed protective agent Ⅰ, mixed protective agent Ⅱ, maltodextrin protective agent, and whey protein powder protective agent for subsequent experiments. The preparation methods are as follows:

[0031] 1. Trehalose protective agent: weigh 18g of trehalose, add 100mL of distilled water and stir until no particles exist;

[0032] 2. Mixed protective agent Ⅰ: Weigh 6g of maltodextrin and 12g of trehalose respectively, add to 100mL of distilled water and stir until no particles exist;

[0033] 3. Mixed protective agent II: Weigh 6g of maltodextrin, 2g of β-cyclodextrin and 10g of whey protein powder into 100mL of distilled water and stir until no particles exist;

[0034] 4. Maltodextrin protective agent: weigh 18g of maltodextrin, add it into 100mL distilled water and stir until no particles exist;

[0035] 5. Protective agent for whey protein powder: Weigh 18g of wh...

Embodiment 3

[0036] Example 3 Nattokinase Crude Enzyme Liquid Drying Experiment

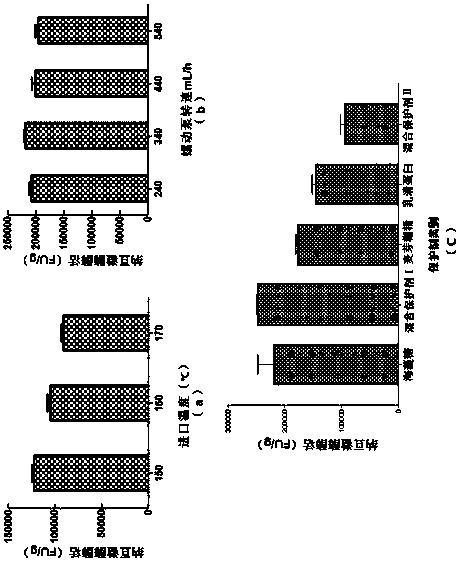

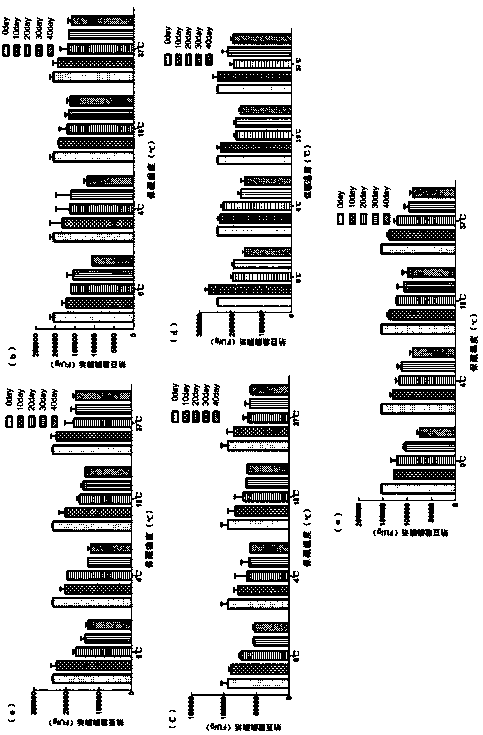

[0037] 1. Optimization of spray drying conditions for nattokinase crude enzyme solution

[0038] According to the nattokinase crude enzyme liquid and various protective agents prepared in Example 2, mix them in a volume ratio of 1:3 (V / V), spray dry them after 10000r / min homogenization for 2 minutes, and set the spray dryer The inlet temperatures were 140, 150, and 160°C, the outlet temperatures were 75°C, the peristaltic pump speeds were 240, 340, and 440mL / h, the fan speed was 70Hz, the firing time was 1s, and the firing interval was 1s. After drying, the enzyme powder was collected for activity determination. The effects of protective agent type, spray drying inlet temperature and spray drying peristaltic pump speed on the activity of nattokinase were investigated.

[0039]Taking the activity of nattokinase as the assessment index, determine the appropriate spray drying conditions for each single factor, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com