Green leather preparation method without heavy metal pollution

A heavy metal and leather technology, applied in leather impregnation, leather surface treatment, chemical instruments and methods, etc., can solve the problems of non-elimination, high discharge of chromium-containing solid waste and wastewater in tanning, and low maturity of resource technology Advanced problems, to achieve the effect of reducing COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

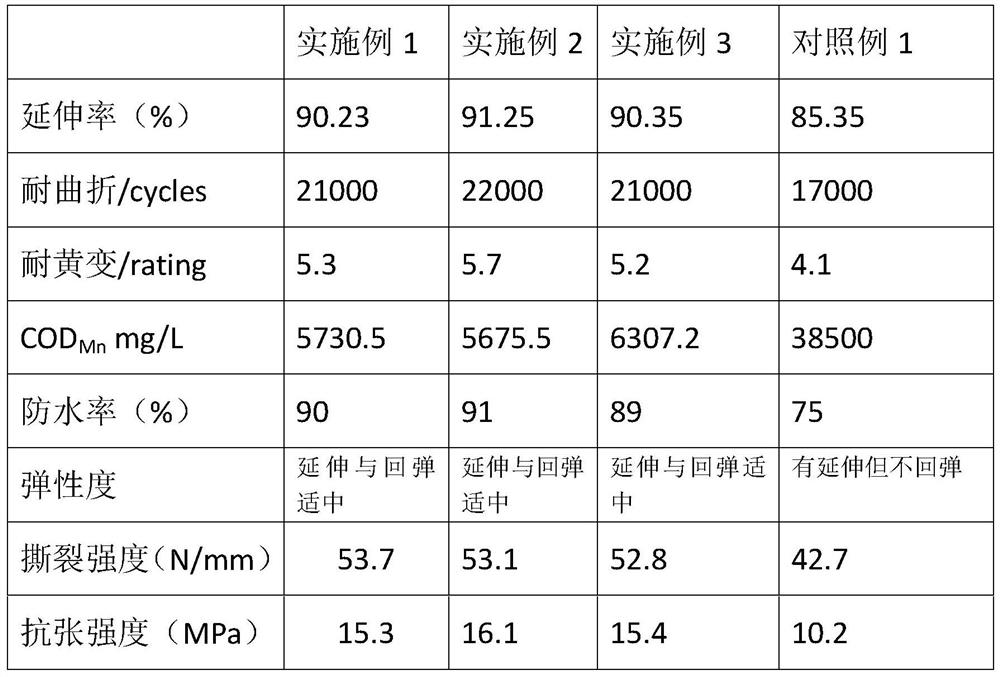

Examples

Embodiment 1

[0017] Get the leather and go through primer coating, rolling finish, middle coating, fixed coating and drum treatment in order to get the finished leather product. Add water-based emulsion and 25 parts of anionic polyurethane dispersion to 100 parts of deionized water in turn, raise the temperature to 30°C, stir evenly, roll coat the surface of the skin embryo with a roller coater, bake at 80°C for 20 minutes, and naturally cool down to room temperature. Add 5 parts of nano-photocatalyst and 50 parts of modified acrylic resin under light conditions, spray evenly on the leather surface, and bake at 70°C;

[0018] The modification method of the modified polysiloxane aqueous emulsion is as follows: in parts by weight, 50 parts of epoxy resin, 2 parts of silane coupling agent, 2 parts of auxiliary agent, put into 80 parts of organic solvent and stir at high speed for 0.5h, add 0.2 Part of defoamer, 0.2 part of leveling agent, mix evenly;

[0019] The modified acrylic resin is a ...

Embodiment 2

[0027] Take the leather and go through primer coating, rolling finish, intermediate coating, fixed coating and drum treatment in order to get the finished leather product. Add water-based emulsion and 27 parts of anionic polyurethane dispersion to 110 parts of deionized water in turn, raise the temperature to 35°C, stir evenly, roll coat on the surface of the leather embryo with a roller coater, bake at 85°C for 22min, and cool down to room temperature naturally. Add 13 parts of nano-photocatalyst and 60 parts of modified acrylic resin under light conditions, spray evenly on the leather surface, and bake at 75°C;

[0028] The modification method of the modified polysiloxane water-based emulsion is: in parts by weight, 75 parts of epoxy resin, 6 parts of silane coupling agent, 3 parts of auxiliary agent, put into 90 parts of organic solvent and stir at high speed for 0.5h, add 0.3 1 part defoamer, 0.3 part leveling agent, mix well;

[0029] The modified acrylic resin is a copo...

Embodiment 3

[0037] Get the leather and get the finished leather through primer, rolling, middle coat, fixed coating and drum treatment successively. 1) The primer described in 1) is: in terms of parts by mass, 15 parts of modified polysiloxane Add water-based emulsion and 30 parts of anionic polyurethane dispersion to 120 parts of deionized water in turn, raise the temperature to 40°C, stir evenly, roll coat on the surface of the leather embryo with a roller coater, bake at 90°C for 25 minutes, and cool down to room temperature naturally. Add 20 parts of nano-photocatalyst and 70 parts of modified acrylic resin under light conditions, spray evenly on the leather surface, and bake at 80°C;

[0038] The modification method of the modified polysiloxane water-based emulsion is: in parts by weight, 100 parts of epoxy resin, 10 parts of silane coupling agent, 4 parts of auxiliary agent, put into 100 parts of organic solvent and stir at high speed for 0.5h, add 0.4 Part of defoamer, 0.4 part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com