A method for efficient deep recovery of hydrogen/deuterium in hydrogen/lithium deuteride

A lithium deuteride, deep technology, applied in the field of nuclear technology applications, can solve the problem of lowering the reaction temperature, etc., to achieve the effect of low reaction temperature, easy handling, and small residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

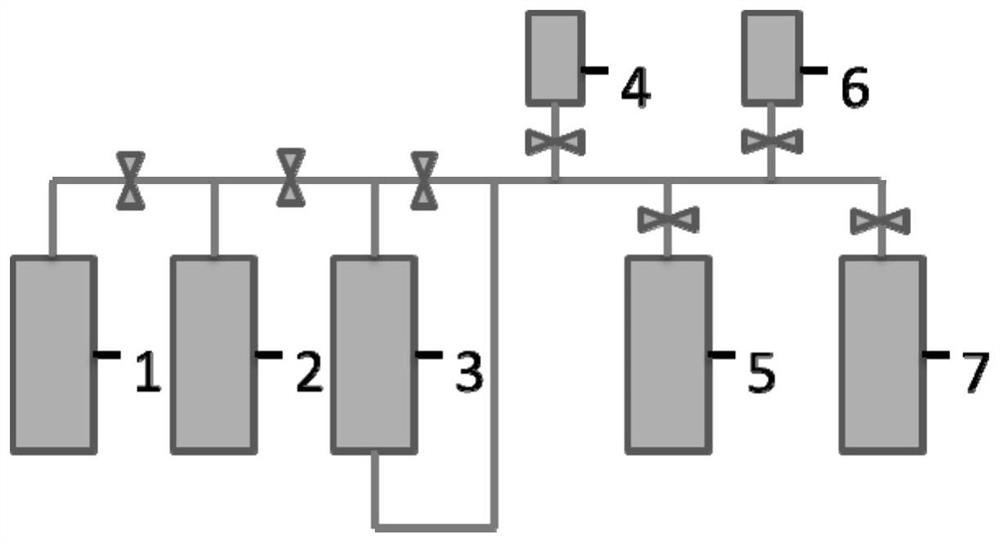

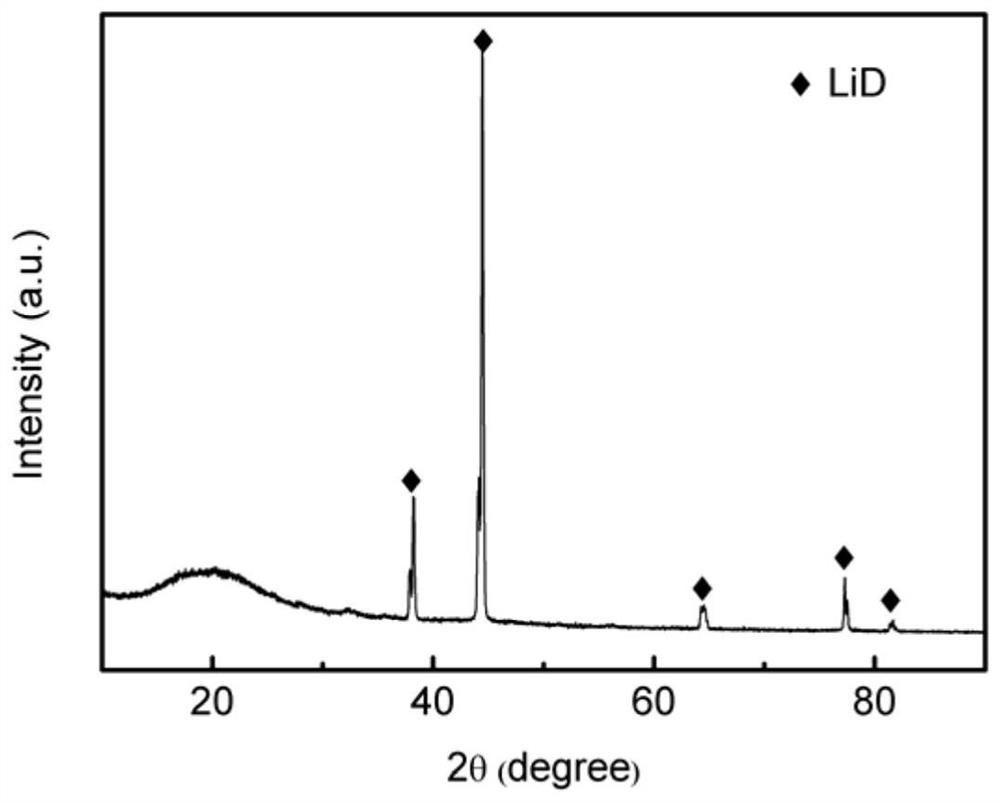

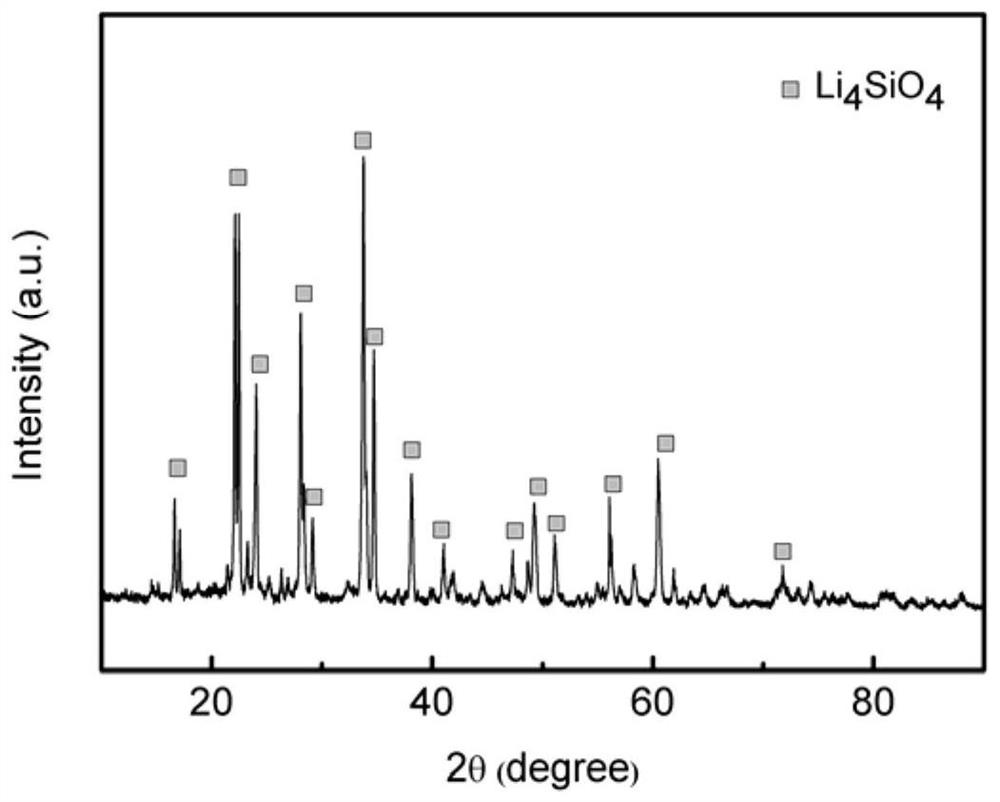

[0038] refer to figure 1 Install the device, evacuate the system to 2Pa, charge to 1.5MPa and keep the pressure for 1h, check for leaks until the leak rate is less than 1.0×10 -9 ·Pa·m3·s -1 for later use. Mesoporous silica SBA-15 (density less than 1g / cm 3 ) heated to 500°C under air atmosphere, calcined at high temperature for 0.5h, and pulverized to less than 100nm. The calcined mesoporous silica SBA-15 and lithium deuteride were uniformly mixed according to the weight ratio of 64:36, and the mixture was pressed into a sheet at a pressure of 25Mpa under the condition of nitrogen protection and loaded into the reactor. Connect the reactor to the system and evacuate the system to below 2Pa, heat to 300°C and lithium deuteride begins to decompose and release deuterium gas. Store the decomposed deuterium gas in a gas standard tank, and use a pressure sensor to record the pressure of the gas. When the pressure value does not change (600°C), the reaction is considered to be o...

Embodiment 2

[0043] Evacuate the system to 2Pa, charge to 1.5MPa and keep the pressure for 1h, the leak rate is less than 1.0×10 -9 ·Pa·m 3 ·s -1 for later use. Microporous silica / alumina MCM-41 (density less than 1g / cm 3 ) heated to 450°C under air atmosphere, calcined at high temperature for 0.5h, and pulverized to less than 100nm. The calcined microporous silica / alumina MCM-41 and lithium deuteride are evenly mixed according to the weight ratio of 79:21, and the mixture is pressed into a sheet at a pressure of 25Mpa under the condition of nitrogen protection and loaded into the reactor. Connect the reactor to the system and evacuate the system to below 2Pa, heat to above 350°C, lithium deuteride begins to decompose and release deuterium gas. Store the decomposed deuterium gas in a gas standard tank, and use a pressure sensor to record the pressure of the gas. When the pressure value does not change (600°C), the reaction is considered to be over. Chromatography is used to analyze th...

Embodiment 3

[0048] Evacuate the system to 2Pa, charge to 1.5MPa and keep the pressure for 1h, the leak rate is less than 1.0×10 -9 ·Pa·m 3 ·s -1 for later use. Mesoporous silica SBA-15 (density less than 1g / cm 3 ) heated to 500°C under air atmosphere, calcined at high temperature for 0.5h, and pulverized to less than 100nm. The calcined mesoporous silica SBA-15 lithium hydride was uniformly mixed according to the weight ratio of 60:40, and the mixture was pressed into a sheet at a pressure of 25Mpa under the condition of nitrogen protection and loaded into the reactor. Connect the reactor to the system and evacuate the system to below 2Pa, heat to above 330°C, lithium hydride begins to decompose and release hydrogen. Store the decomposed hydrogen in a gas standard tank, and use a pressure sensor to record the pressure of the gas. When the pressure value does not change (610°C), the reaction is considered to be over. Chromatography is used to analyze the composition of the gas and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com