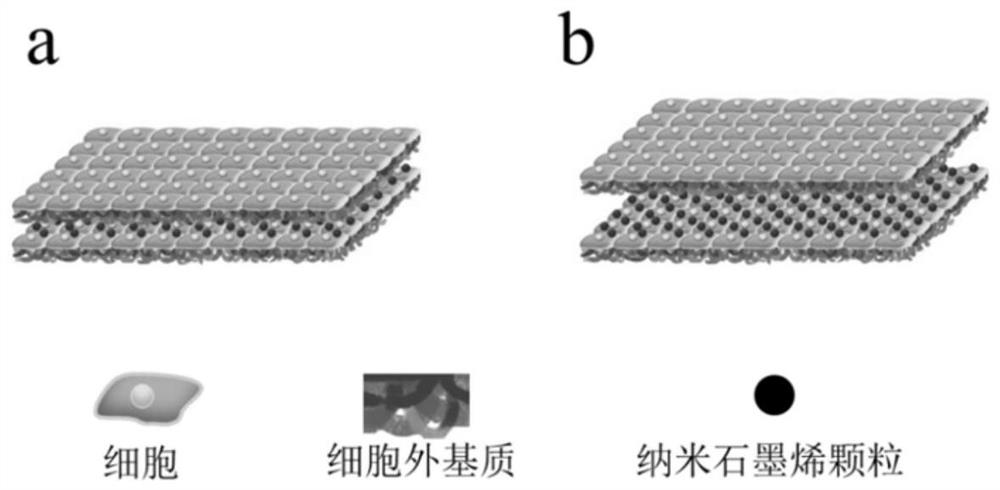

A kind of extracellular matrix composite film with photothermal effect and preparation method thereof

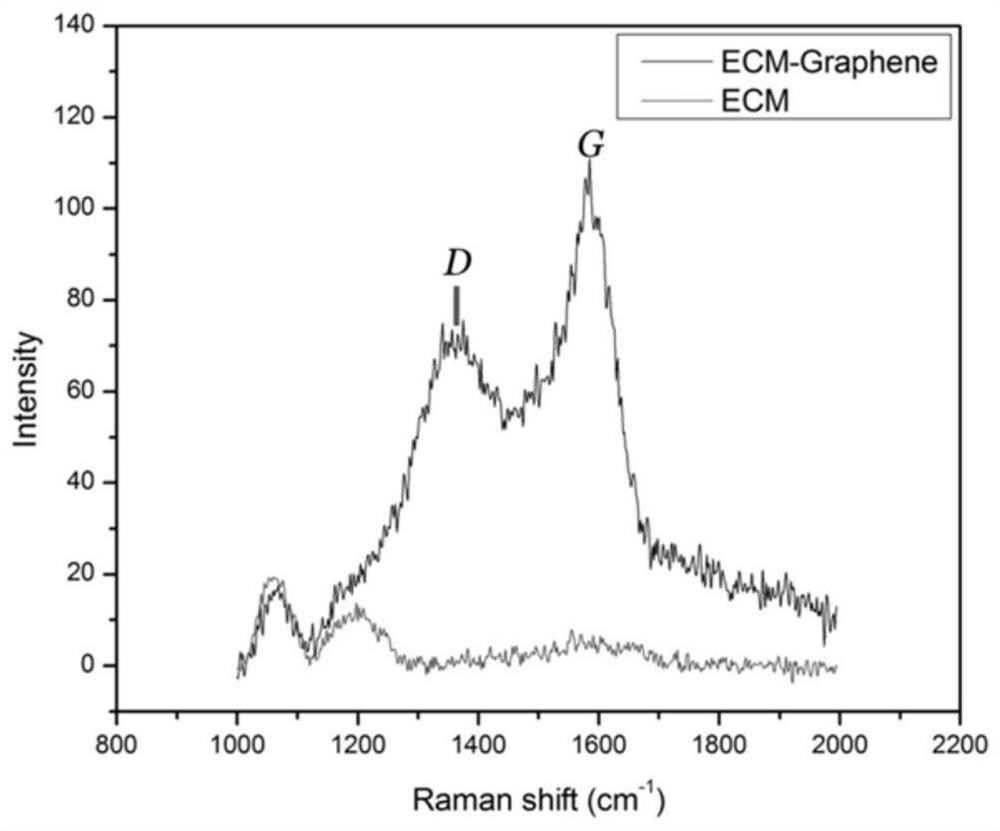

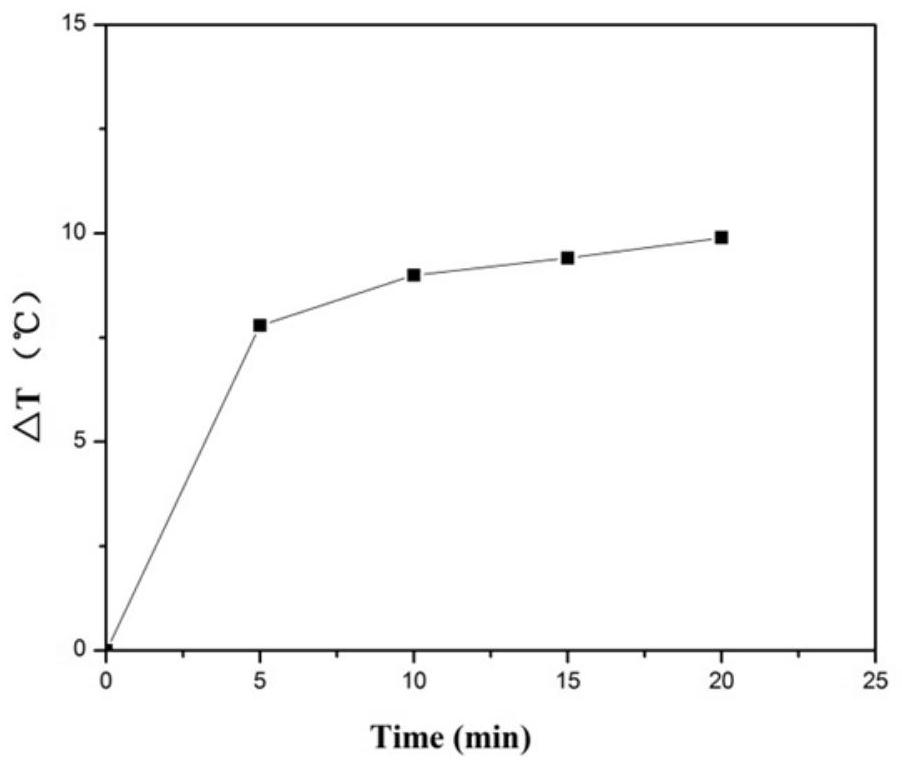

A technology of composite film and photothermal effect, which is applied in the direction of medical preparations containing active ingredients, pharmaceutical formulas, drug combinations, etc., can solve problems affecting cell proliferation and differentiation, changes in the ultrastructure of extracellular matrix, etc., and achieve good photoluminescence. Thermal effect, good light and heat characteristics, the effect of avoiding direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1). Sterilize the cell culture surface on which the visible light-induced cell detachment is performed by autoclaving;

[0028] (2). The cells previously cultured in the culture flask were detached, centrifuged at 1000r / min for 4min, suspended in high-sugar DMEM medium, and counted with a counting plate at 1×10 5 piece / cm 2 The cell density was seeded on the above-mentioned treated cell culture surface, and placed in a constant temperature of 37 ° C, 5% CO 2 Cultured in a cell incubator, the medium was changed once every 2 days, and the culture period was 9 days. In the last day of the culture period, 100 μg / mL nano-graphene particles with a particle diameter of 10 nm were added to form a complete cell culture surface. cell sheet;

[0029] (3). The cultured surface after the above culture was washed with PBS, then soaked in deionized water and then freeze-dried to obtain a cultured surface loaded with an extracellular matrix composite film, and the surface was steril...

Embodiment 2

[0035] (1). Sterilize the cell culture surface on which the visible light-induced cell detachment is performed by autoclaving;

[0036] (2). The cells previously cultured in the culture flask were detached, centrifuged at 800r / min for 6min, suspended in high-sugar DMEM medium, and counted with a counting plate at 2×10 5 piece / cm 2 The cell density was seeded on the above-mentioned treated cell culture surface, and placed in a constant temperature of 37 ° C, 5% CO 2 Cultured in a cell incubator, the medium was changed once every 2 days, and the culture period was 8 days. 90 μg / mL nano-graphene particles with a particle diameter of 15 nm were added on the second-to-last day of the culture period, and finally formed on the surface of the cell culture. the cell sheet;

[0037] (3). The cultured surface after the above culture was washed with PBS, then soaked in deionized water and then freeze-dried to obtain a cultured surface loaded with an extracellular matrix composite film, ...

Embodiment 3

[0042] (1). Sterilize the cell culture surface on which the visible light-induced cell detachment is performed by autoclaving;

[0043] (2). The cells previously cultured in the culture flask were detached, centrifuged at 900r / min for 5min, suspended in high-sugar DMEM medium, and counted with a counting plate at 5×10 5 piece / cm 2 The cell density was seeded on the above-mentioned treated cell culture surface, and placed in a constant temperature of 37 ° C, 5% CO 2 Cultured in a cell culture box, the medium was changed once every 2 days, and the culture period was 7 days. 80 μg / mL nano-graphene particles with a particle diameter of 20 nm were added on the penultimate day of the culture period, and finally formed on the surface of the cell culture. the cell sheet;

[0044] (3). The cultured surface after the above culture was washed with PBS, then soaked in deionized water and then freeze-dried to obtain a cultured surface loaded with an extracellular matrix composite film, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com