Flue gas denitrification system

A flue gas and denitrification technology, which is applied in the field of flue gas denitrification system, can solve the problems of affecting the service life of the booster system, increasing the operating cost of the flue gas denitrification system, increasing the manufacturing cost and technical difficulty of the booster system, and achieving the goal of reducing losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

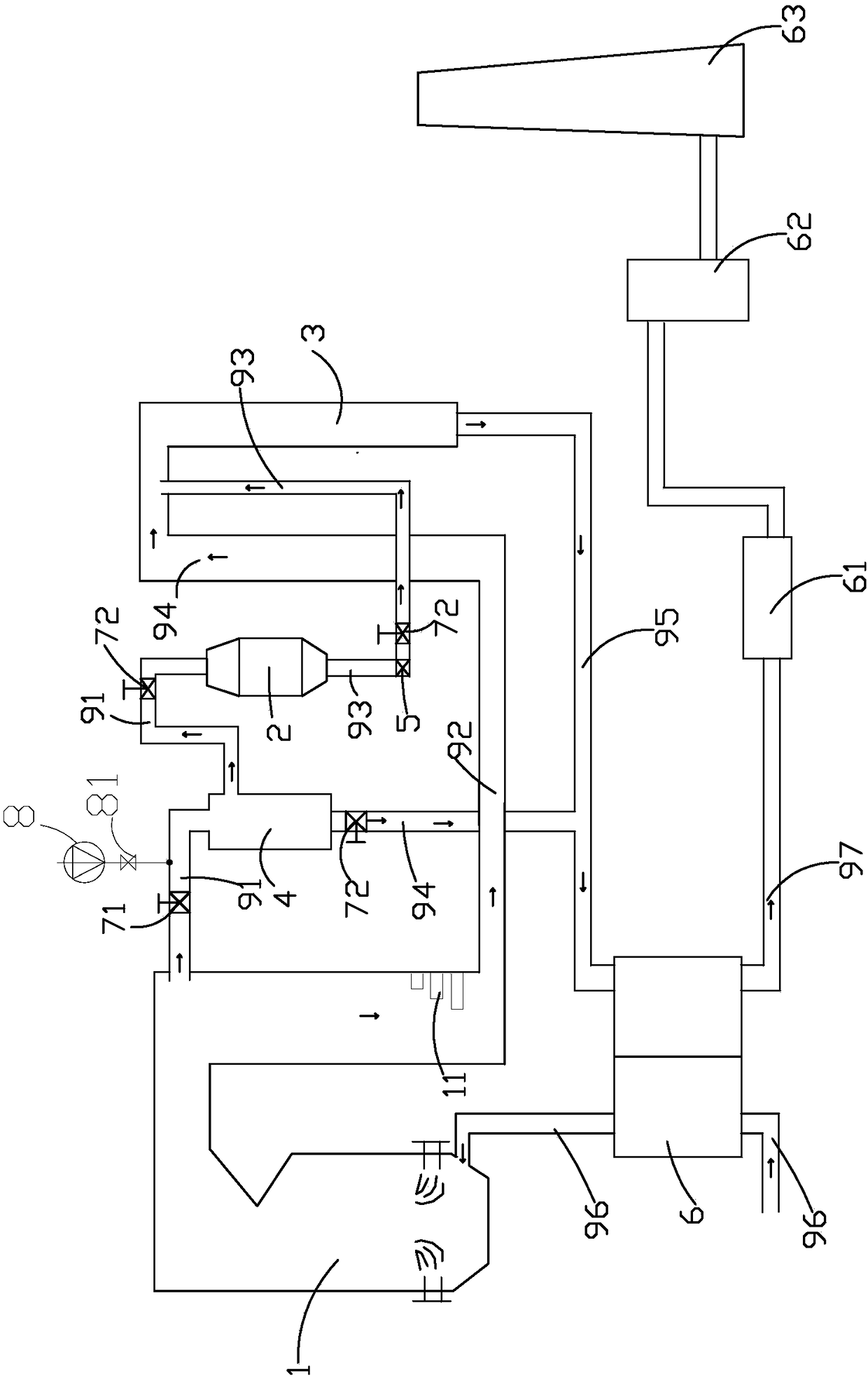

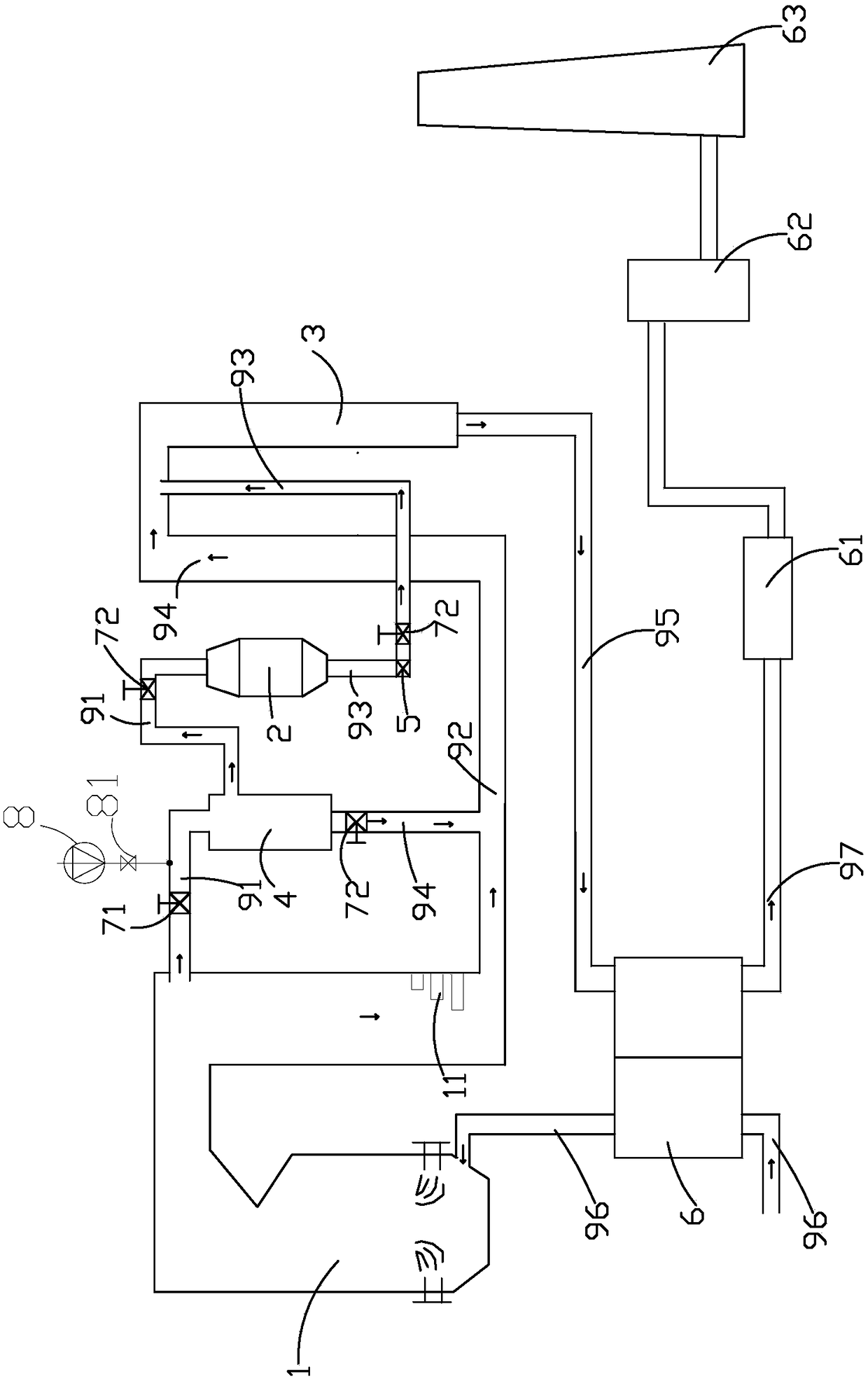

[0019] Such as figure 1 As shown, it is the first embodiment of a flue gas denitrification system involved in the invention, which includes a boiler furnace 1, a pyrolysis mechanism 2, an SCR reactor 3, a dust collector 4, a draft and booster mechanism 5, an air preheating Device 6, main valve 71, multiple air valves 72, cold air system 8 and pipeline system. The boiler furnace 1 is a device for generating high-temperature flue gas.

[0020] The piping system includes a flue gas pipe 91, a furnace flue 92, an air outlet pipe 93, a dust discharge pipe 94, a flue gas discharge pipe 95 and a primary hot air pipe 96; one end of the flue gas pipe 91 is connected to the boiler furnace 1, and the other is One end communicates with the pyrolysis mechanism 2 . In this embodiment, the flue gas pipe 91 is connected to the upper end of the boiler furnace 1, or it can be understood that the place where the flue gas pipe 91 is connected to the boiler furnace is an area that can extract hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com