Hydrotalcite-based composite gel ball as well as preparation method and application thereof

A composite gel and hydrotalcite-based technology, applied in chemical instruments and methods, water pollutants, and other chemical processes, can solve problems such as lack of good selectivity, adsorbent biotoxicity, and difficulty in recycling, and achieve the goal of preparing raw materials Low cost, high adsorption rate, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

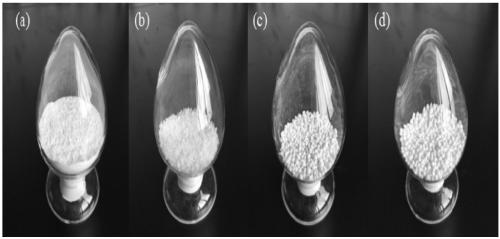

[0036] In view of this, in a specific embodiment of the present invention, a kind of preparation method of hydrotalcite-based composite gel ball is provided, comprising the following steps:

[0037] (1) Dissolve SA in deionized water, stir continuously and ultrasonically disperse to obtain a uniform and transparent colloidal solution;

[0038] (2) Add CLDH to the solution of step (1), continuously stir and ultrasonically disperse, let stand for defoaming, and obtain a homogeneous suspension;

[0039] (3) CaCl 2 Dissolved in deionized water to obtain a homogeneous transparent solution;

[0040] (4) Add the solution of step (2) dropwise to the solution of step (3) in a water bath at 20-60°C with constant stirring through a peristaltic pump, and stir for 1 to 12 hours. After the reaction is complete, stir and solidify at room temperature for 12 hours. ~48h, take out the gel ball, wash with deionized water to remove excess Ca 2+ , freeze-dried to obtain hydrotalcite-based compo...

Embodiment 1

[0053] Embodiment 1: A kind of preparation method of hydrotalcite-based composite gel ball

[0054] (1) 0.6 g of SA with a viscosity of 1000 mpa·s was dissolved in 20 mL of deionized water, stirred continuously and ultrasonically dispersed to obtain a homogeneous and transparent colloidal solution of SA with a mass volume fraction of 3%;

[0055] (2) 1g CaCl 2 Dissolved in 50mL deionized water to obtain CaCl with a mass volume fraction of 2% 2 homogeneous transparent solution;

[0056] (3) Add the solution of step (1) dropwise to the solution of step (2) in a 40°C water bath at a speed of 5r / min through a peristaltic pump at a speed of 40r / min, and continue to stir for 2h. Stir and solidify under the state for 24h, take out the gel ball, wash away the excess Ca with deionized water 2+ , Freeze-dried to obtain hydrotalcite-based composite gel balls 1:0% CLDH-SA gel balls.

Embodiment 2

[0057] Embodiment 2: A kind of preparation method of hydrotalcite-based composite gel ball

[0058] (1) 0.2 g of SA with a viscosity of 550 mpa·s was dissolved in 20 mL of deionized water, stirred continuously and ultrasonically dispersed to obtain a homogeneous and transparent colloidal solution of SA with a mass volume fraction of 1%;

[0059] (2) Add 0.4g CLDH to the colloidal solution of step (1), continuously stir and ultrasonically disperse, leave to stand for defoaming, and obtain a homogeneous suspension;

[0060] (3) 1g CaCl 2 Dissolved in 50mL deionized water to obtain CaCl with a mass volume fraction of 2% 2 homogeneous transparent solution;

[0061] (4) Add the solution of step (2) dropwise to the solution of step (3) in a 30°C water bath at a speed of 5r / min through a peristaltic pump at a speed of 150r / min, and continue to stir for 2h. Stir and solidify under the state for 12h, take out the gel ball, and wash away the excess Ca with deionized water 2+ , Freez...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com