Production technology of high-purity, ultrafine and high-whiteness natural barium sulfate

A natural barium sulfate, production process technology, applied in the direction of calcium/strontium/barium sulfate, calcium/strontium/barium halide, calcium/strontium/barium compound, etc., can solve the poor dispersion of chemically synthesized barium sulfate, production Problems such as large equipment investment and complex production process achieve good economic and environmental benefits, low production cost and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

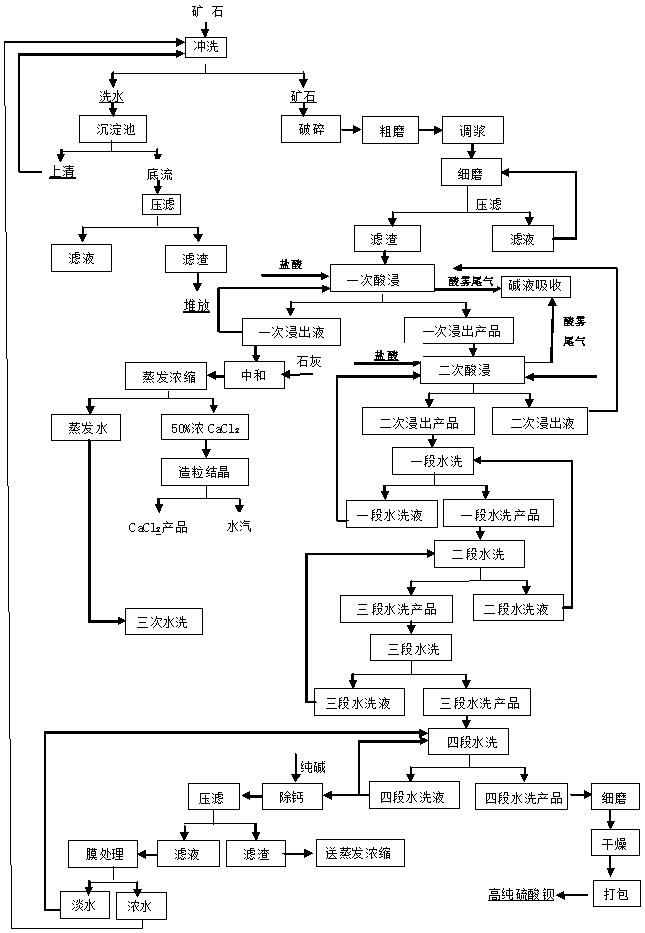

[0034] The invention discloses a process for producing high-purity, ultra-fine, high-whiteness natural barium sulfate, which is characterized by including the following processes: a crushing process, an acid leaching process, a water washing process, an evaporation concentration process, and a membrane treatment process.

[0035] S1, crushing process:

[0036] The raw barite ore is washed to remove the silt and other impurities in the raw ore. The washed ore is crushed and coarsely ground to a particle size of D90 or less than 200 mesh. Then the slurry is adjusted, the barite ore powder and water are mixed and slurryed at a ratio of 1:1, and the slurry after slurrying is finely ground to make the particle size reach D90 below 1000 mesh. The finely ground pulp is filtered by pressure to obtain filtrate and filter residue. The filtrate does not contain impurities such as acid, alkali and calcium, and is recycled in this process. The resulting filter residue enters the next process....

Embodiment 2

[0055] The invention discloses a process for producing high-purity, ultra-fine, high-whiteness natural barium sulfate, which is characterized by including the following processes: a crushing process, an acid leaching process, a water washing process, an evaporation concentration process, and a membrane treatment process.

[0056] S1, crushing process:

[0057] The raw barite ore is washed to remove the silt and other impurities in the raw ore. The washed ore is crushed and coarsely ground to a particle size of D90 or less than 200 mesh. Then the slurry is adjusted, the barite ore powder and water are mixed and slurryed at a ratio of 1:1, and the slurry after slurrying is finely ground to make the particle size reach D90 below 1000 mesh. The finely ground pulp is filtered by pressure to obtain filtrate and filter residue. The filtrate does not contain impurities such as acid, alkali and calcium, and is recycled in this process. The resulting filter residue enters the next process....

Embodiment 3

[0076] The invention discloses a process for producing natural barium sulfate with high purity, ultrafine and high whiteness, which is characterized in that it includes the following steps:

[0077] S1, crushing process:

[0078] The raw barite ore is washed to remove the silt and other impurities in the raw ore. The washed ore is crushed and coarsely ground to a particle size of D90 or less than 200 mesh. Then the slurry is adjusted, the barite ore powder and water are mixed and slurryed at a ratio of 1:1, and the slurry after slurrying is finely ground to make the particle size reach D90 below 1000 mesh. The finely ground pulp is filtered by pressure to obtain filtrate and filter residue. The filtrate does not contain impurities such as acid, alkali and calcium, and is recycled in this process. The resulting filter residue enters the next process.

[0079] S2, acid leaching process:

[0080] One stage of acid leaching: The filter residue after the fine grinding and pressure filtr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com