Low-temperature scouring agent and preparation method thereof

A scouring agent, low temperature technology, applied in the field of low temperature scouring agent and its preparation, can solve the problems of ineffective removal of cotton wax, low wicking height of fabrics, easy wrinkle printing, etc., to achieve excellent wettability and permeability, improve Removal effect, effect of increasing wicking height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

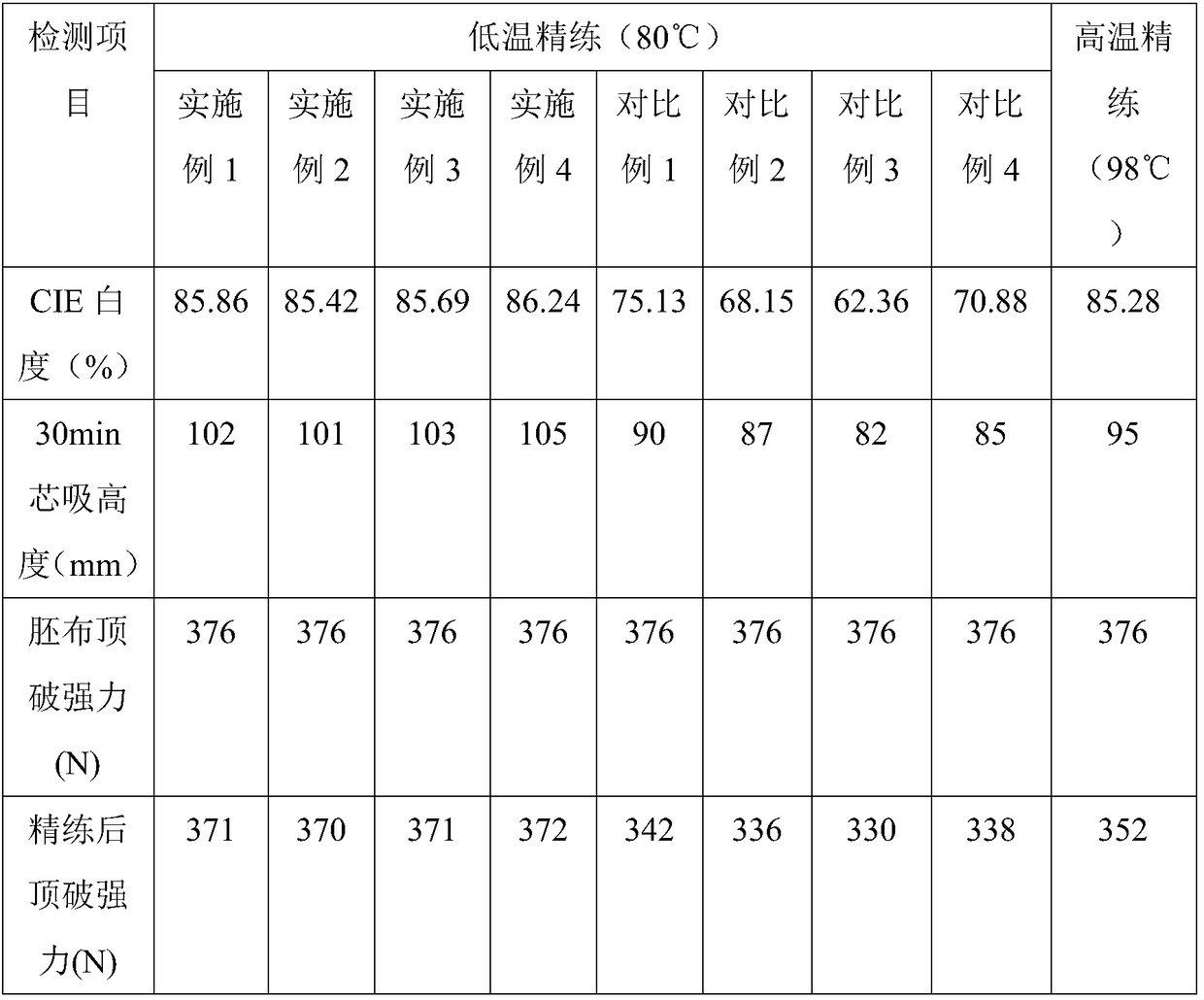

Examples

Embodiment 1

[0032] Embodiment 1, a kind of low temperature scouring agent

[0033] The low-temperature scouring agent is composed of the following components and their weight percentages: 0.2% hydrogen peroxide activator, 21.8% low-foaming surfactant, 3% deionized water 75%; the hydrogen peroxide activator is imino di Ferrous succinate; The low-foaming surfactant is composed of isooctyl alcohol polyoxyethylene ether (EO number is 3), isomeric decanol polyoxyethylene ether (EO number is 5) and isomeric tridecyl alcohol polyoxyethylene The ether (EO number is 3) is composed in a weight ratio of 1:7:12; the auxiliary training agent is diethylene glycol butyl ether.

[0034] Preparation:

[0035] S1 Mix the low-foaming surfactant and the training aid, and stir at a speed of 400r / min for 25min to obtain a mixed solution;

[0036] S2 Add hydrogen peroxide activator to the mixed liquid obtained in step S1, stir at a speed of 300r / min for 10min, add deionized water, stir evenly, and obtain.

Embodiment 2

[0037] Embodiment 2, a kind of low temperature scouring agent

[0038]The low-temperature scouring agent is composed of the following components and their weight percentages: 0.8% of hydrogen peroxide activator, 39.2% of low-foaming surfactant, 10% of auxiliary scouring agent, and 50% of deionized water; Ferrous succinate and ferrous gluconate are composed of 2:5 by weight; the low-foaming surfactant consists of isooctyl alcohol polyoxyethylene ether (EO number is 5), isomeric decanol polyoxyethylene ether (EO number 10) and isomeric tridecyl alcohol polyoxyethylene ether (EO number is 10) in a weight ratio of 2:5:9; the auxiliary refining agent is tripropylene glycol butyl ether.

[0039] Preparation:

[0040] S1 Mix the low-foaming surfactant and the training aid, and stir for 35 minutes at a speed of 600r / min to obtain a mixed solution;

[0041] S2 Add hydrogen peroxide activator to the mixed liquid obtained in step S1, stir at a speed of 400r / min for 15min, add deionized...

Embodiment 3

[0042] Embodiment 3, a kind of low temperature scouring agent

[0043] The low-temperature scouring agent is made up of the following components and their weight percentages: 0.75% of hydrogen peroxide activator, 36.25% of low-foaming surfactant, 8% of auxiliary scouring agent, and 55% of deionized water; the hydrogen peroxide activator consists of salicylaldehyde Manganese taurine complex, ferrous iminodisuccinate and ferrous gluconate are composed of 5:2:1 by weight; the low-foaming surfactant is composed of isooctyl alcohol polyoxyethylene ether (EO number is 4), isomeric decanol polyoxyethylene ether (EO number is 7) and isomeric tridecyl alcohol polyoxyethylene ether (EO number is 5) by weight ratio 1:6:10; pentylene glycol.

[0044] The preparation method of described salicylaldehyde taurate manganese complex is:

[0045] (1) Get taurine and potassium hydroxide of the amount of the same substance, add deionized water, the addition of deionized water is 30 times of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com