Low-noise efficient axial-flow fan

An axial-flow fan, low-noise technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of complexity, limited noise reduction, and difficulty in achieving effective fan noise reduction, and achieves improved efficiency and light weight. , the effect of reducing material cost and processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

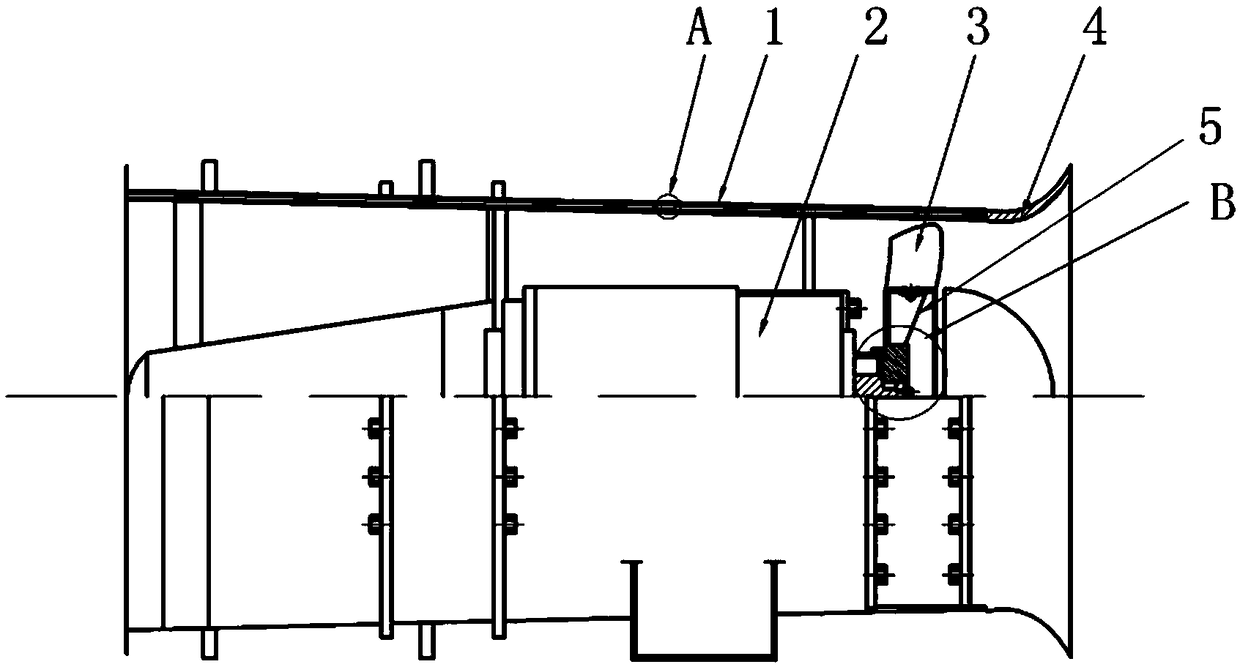

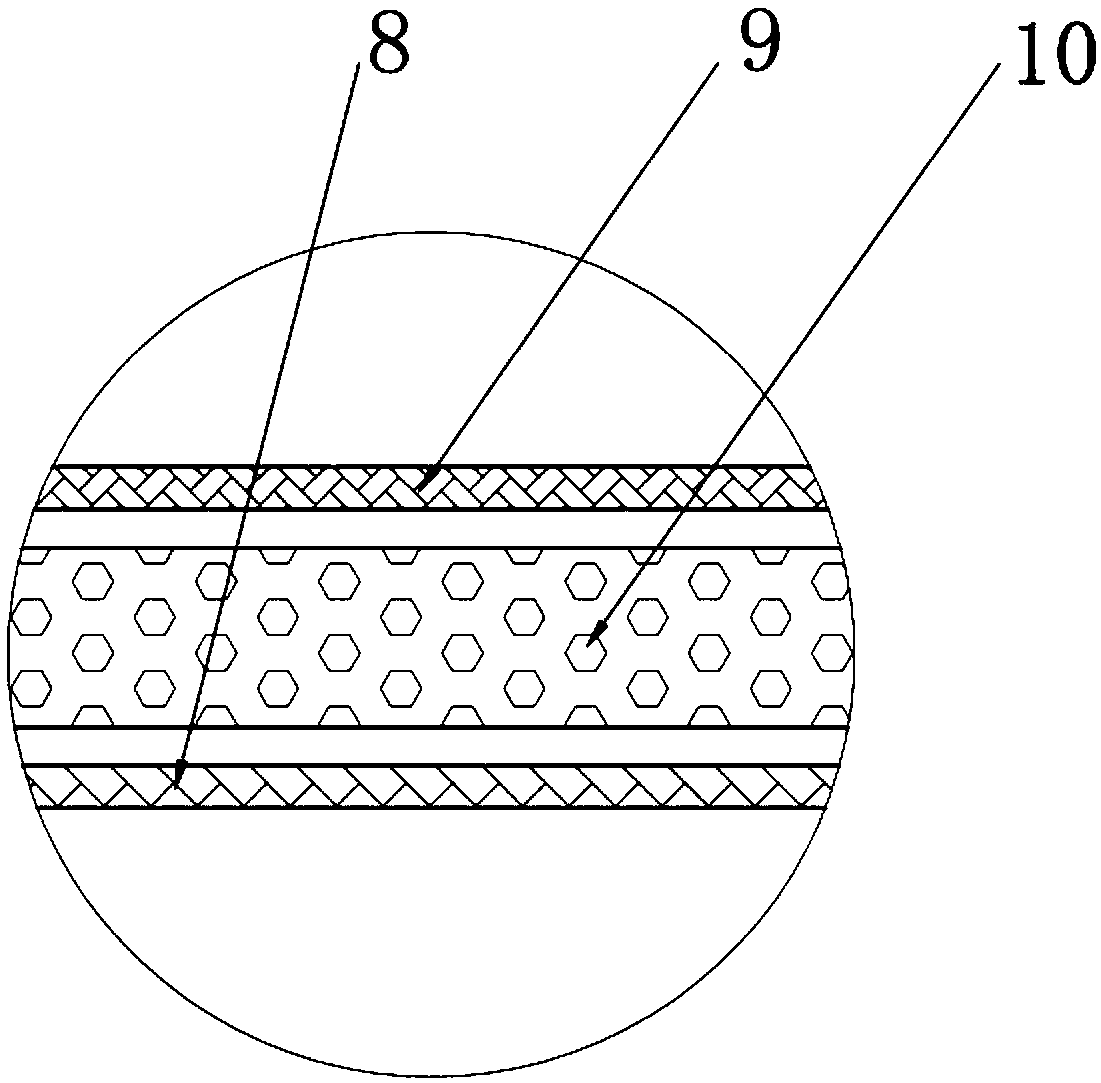

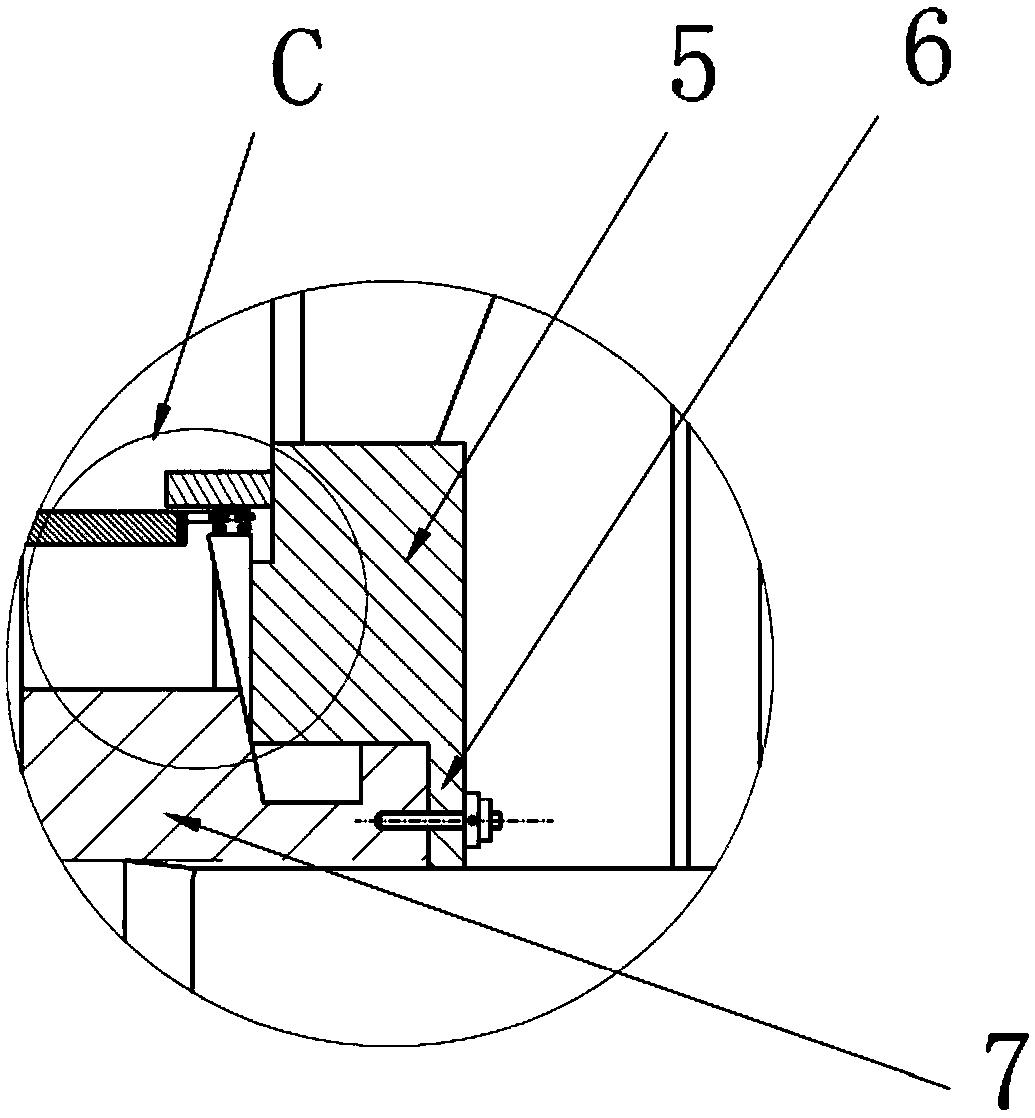

[0023] The reference signs in the drawings of the specification include: silent cover 1, motor 2, blade 3, current collector 4, hub 5, fixed plate 6, motor shaft 7, carbon steel inner layer 8, carbon steel outer layer 9 , Porous foam metal plate 10, connecting rod 11, fixed rod 12, wedge block 13, inner cam ring 14, roller 15, slide bar 16, pressing spring 17, sawtooth 18.

[0024] Embodiment: the low-noise high-efficiency axial fan in this scheme, such as figure 1 and figure 2 As shown, it includes a cylindrical silent cover 1, and the silent cover 1 is composed of a carbon steel inner layer 8, an inner layer of glass wool, a porous foam metal plate 10, an outer layer of glass wool, and a carbon steel outer layer 9. In order to reduce the Mechanical vibration noise between the carbon steel inner layer 8 and the porous metal foam plate 10, between the carbon steel inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com