A method for evaluating the performance of powder coke adsorption of sulfur dioxide/hcl based on entrained flow

An evaluation method, the technology of entrained flow bed, which is applied in the direction of using material absorption and weighing, can solve the problems of inappropriate powder activated coke, inability to simulate the adsorption state of powder activated coke, and inability to measure the intrinsic adsorption rate of activated coke. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

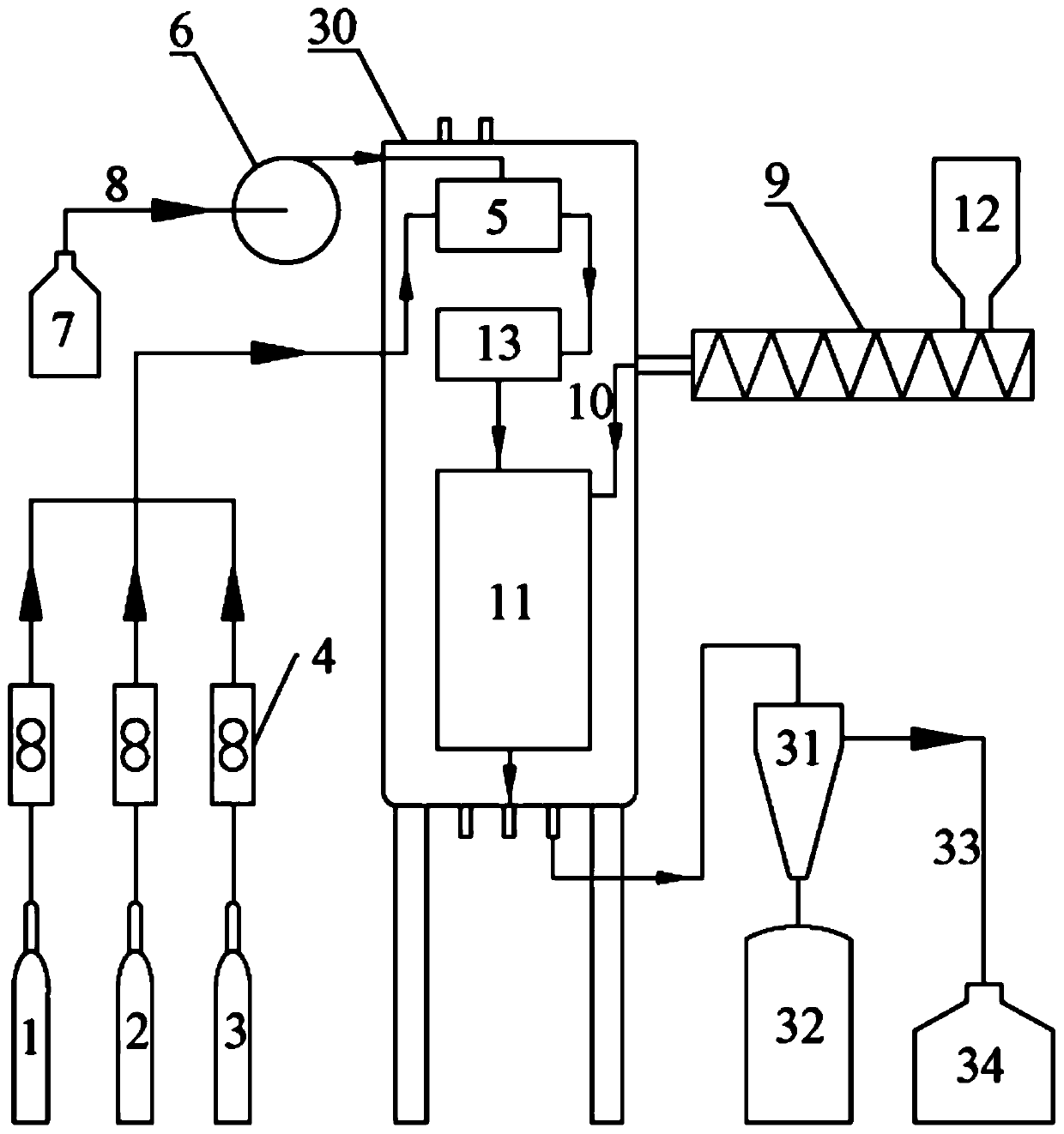

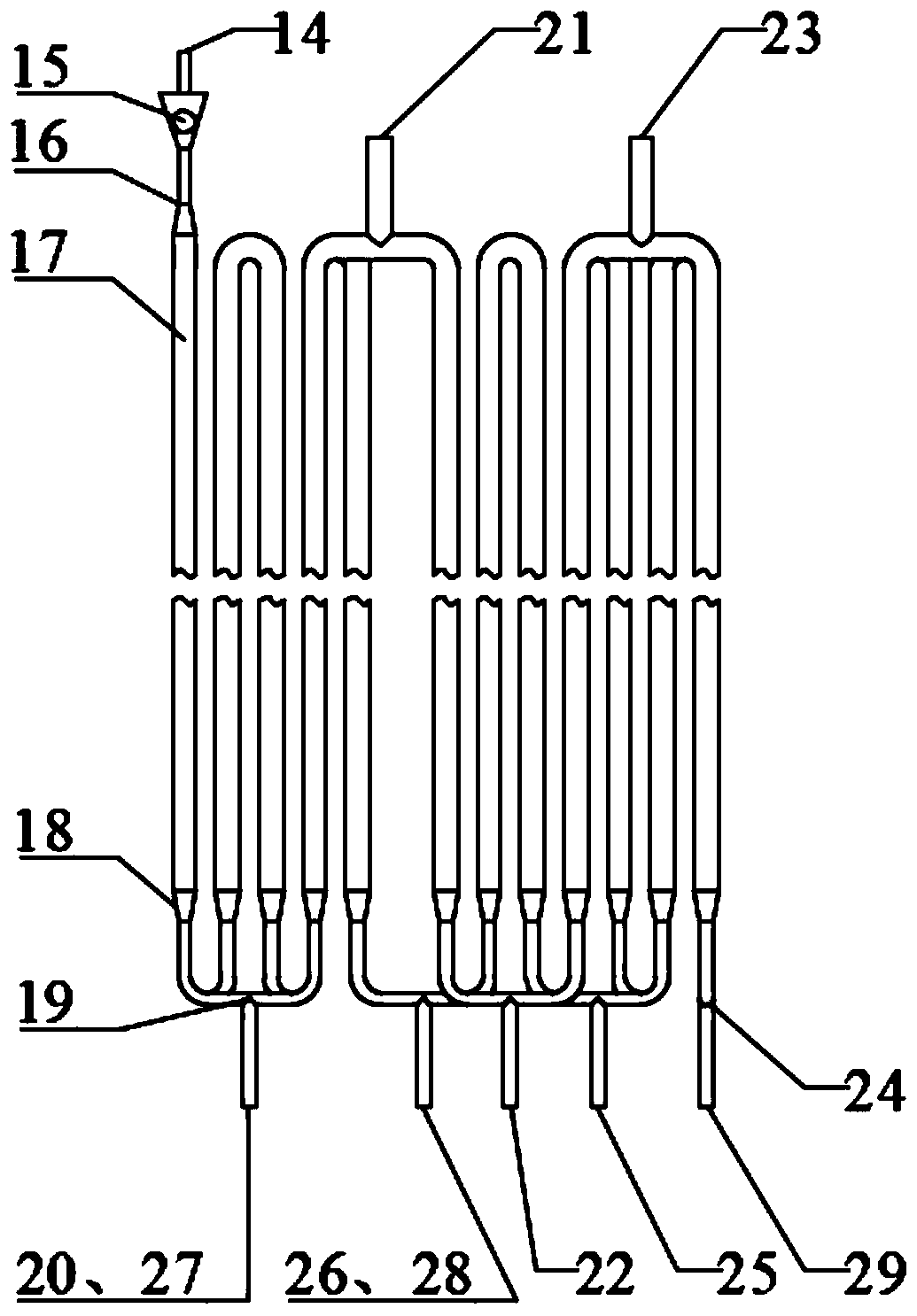

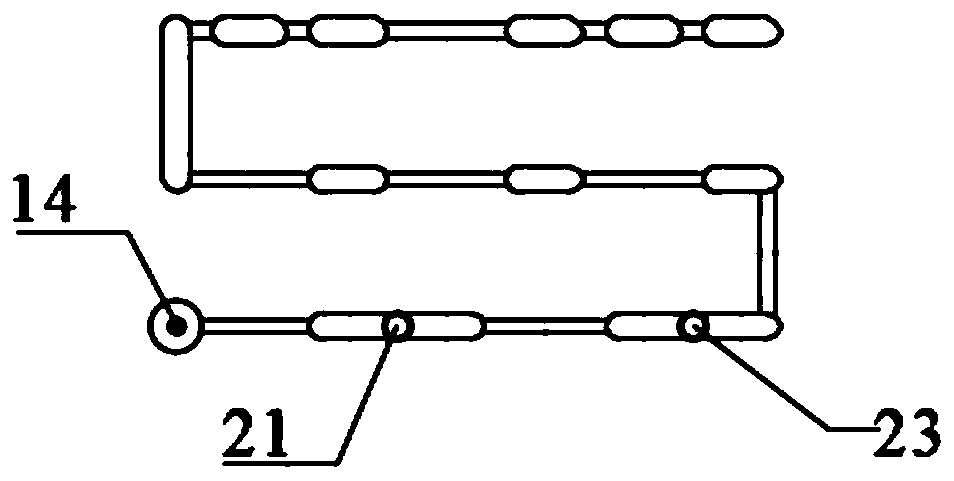

[0063] systems such as Figure 1~4 As shown, it includes adsorption gas generating device, coke powder feeding device, temperature control and heat preservation device, serpentine tube adsorption reactor, gas-solid separation device and tail gas treatment device.

[0064] The adsorption gas generating device includes gas cylinders (high-purity nitrogen cylinder 1, high-purity oxygen cylinder 2, SO 2 Standard gas cylinder 3), mass flow controller 4 and steam generator 5, and adopt peristaltic pump 6 to absorb water from water tank 7 to provide ultrapure water 8 with stable flow for steam generator 5.

[0065] The steam generating device 5 is a cylindrical metal shell, which is heated by an electric heating wire, and an appropriate amount of heat storage ceramics is installed inside, and the water droplets sent by the peristaltic pump 6 evaporate instantly to water vapor.

[0066] The main body of the coke powder feeding device is a screw feeder 9, which is used to send powder...

Embodiment 2

[0071] combine Figure 1~4 , a powder coke adsorbing SO 2 The performance evaluation method includes the following steps:

[0072] 1. Preparation part:

[0073] (1) Sieve the powdered active coke to be tested to obtain powdered coke particles with different particle sizes (50-200 μm);

[0074] (2) Pour powder coke with an average particle size of 75 μm (the powder coke that can pass through a 160-mesh sieve but cannot pass through a 250-mesh sieve has a particle size distribution of 58 to 96 μm, and its average particle size is 75 μm) into the screw feeder The feed bin 12 of the feeder 9 is turned on the feeder motor, and the feeding amount is calibrated (10g / h);

[0075] (3) Turn on the power supply of the steam generating device 5 and the gas heater 13, and after the temperature reaches the set value, turn on the peristaltic pump 6 to set the water supply and open each gas cylinder 1-3 to prepare the simulated flue gas: The concentration of each component in the simulate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com