A magnetic conductive sheet for wireless char and a preparation method thereof

A technology of wireless charging and magnetic conductive sheet, which is applied in the field of magnetic conductive sheet, can solve the problems such as difficulty in reducing the thickness, and achieve the effects of controllable thickness, good uniformity and performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

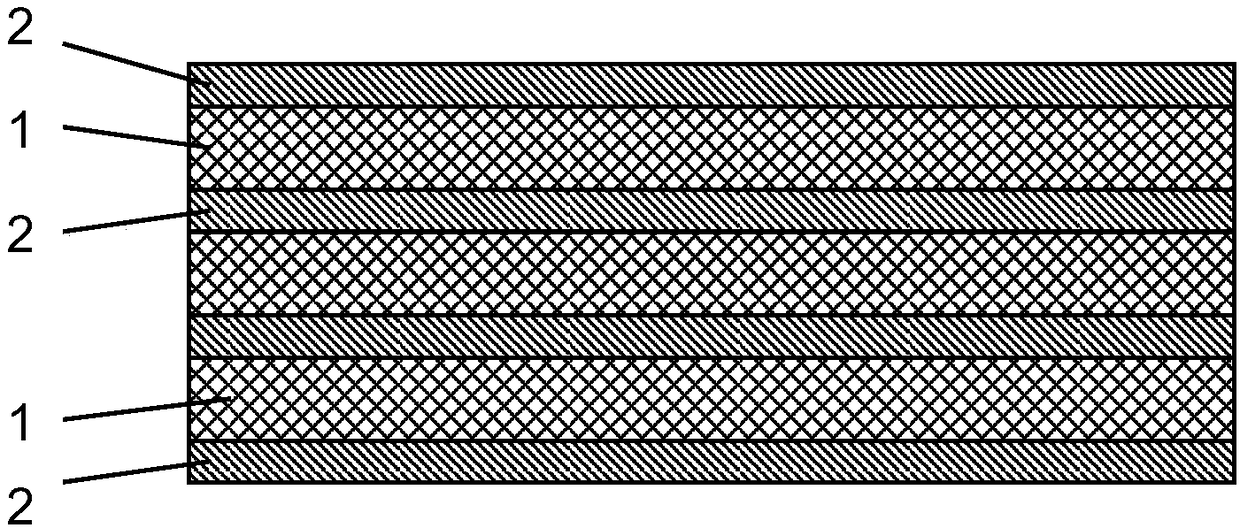

[0032] The magnetic conductive sheet for wireless charging of the present invention is such as figure 1 As shown, it mainly includes several layers of permalloy layer 1 stacked on top of each other and patterned with magnetic sheets. The permalloy layer is bonded by the coating layer 2 provided on the upper and lower sides of the permalloy layer 1 and passes through the layer. Pressed.

[0033] As an embodiment, the permalloy layer is made of an ultra-thin permalloy strip with a thickness of 5-15 μm.

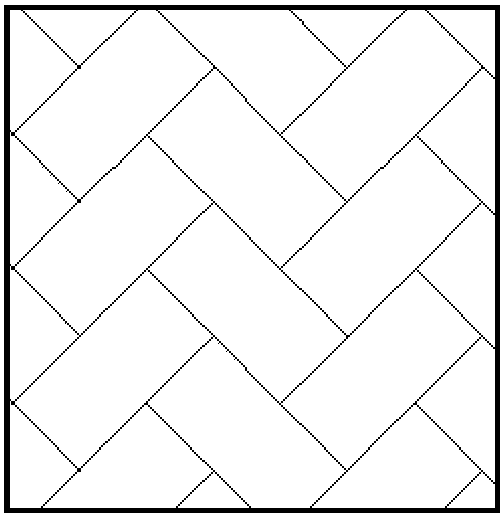

[0034] Please combine image 3 As shown, the method for preparing the magnetic conductive sheet for wireless charging specifically includes the following steps:

[0035] 1) Material preparation stage: prepare ultra-thin permalloy strips with a thickness of 5-15μm and prepare adhesive glue; in addition, relevant production equipment, such as heat treatment equipment, test analysis equipment, and graphical processing equipment, are also required.

[0036] 2) Heat treatment: After the perm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com