A preparation method of a positive electrode functional separator applied in a lithium sulfur battery

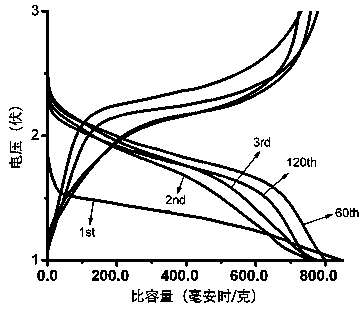

A lithium-sulfur battery, functional technology, applied in the field of preparation of positive electrode functional interlayer, can solve the problems of poor performance of lithium-sulfur batteries, low utilization of active materials, etc., to achieve rich mesopores and micropores, reaction reversibility The effect of improving and increasing the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

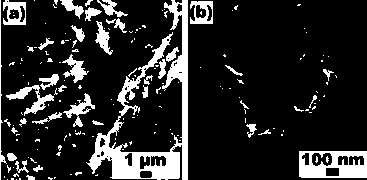

[0026] (1) Preparation of silica-polyacrylonitrile

[0027] Using N,N-dimethylformamide (DMF) as a solvent for PAN polymer and silica, the SiO 2 Stir and dissolve into the PAN / DMF solution to obtain the electrospinning precursor solution, wherein DMF:PAN:SiO 2 Weigh according to the mass ratio of 8:1:1. Inhale the precursor solution into the syringe, and perform electrospinning with the following parameters: adjust the distance between the needle tip and the receiving cylinder to a set distance of 25cm, apply a voltage of 18kV, inject the pump at a rate of 0.3ml / h, and collect the rotating speed at 500 rpm;

[0028] (2) Pretreatment of silica-polyacrylonitrile

[0029] The silica-polyacrylonitrile obtained in step (1) was stabilized in air at 260 °C for 4 h, and the heating rate was 1 °C / min;

[0030] (3) Carbonization treatment of silica-polyacrylonitrile

[0031] The pretreated silica-polyacrylonitrile film was carbonized under a nitrogen atmosphere at a heating rate of ...

Embodiment 2

[0039] (1) Preparation of silica-polyacrylonitrile

[0040] Using N,N-dimethylformamide (DMF) as a solvent for PAN polymer and silica, the SiO 2 Stir and dissolve into the PAN / DMF solution to obtain the electrospinning precursor solution, wherein DMF:PAN:SiO 2 Weigh according to the mass ratio of 8:1:0.5. Inhale the precursor solution into the syringe, and perform electrospinning with the following parameters: adjust the distance between the needle tip and the receiving cylinder to a set distance of 25cm, apply a voltage of 18kV, inject the pump at a rate of 0.3ml / h, and collect the rotating speed at 500 rpm;

[0041] (2) Pretreatment of silica-polyacrylonitrile

[0042] Stabilize the silica-polyacrylonitrile obtained in step (1) at 280 °C in air for 3 h, and the heating rate is 1 °C / min;

[0043] (3) Carbonization treatment of silica-polyacrylonitrile

[0044] The pretreated silica-polyacrylonitrile film was carbonized under a nitrogen atmosphere at a heating rate of 5 °C...

Embodiment 3

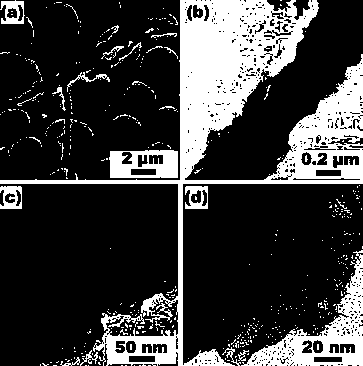

[0050] Step 1: Preparation of silica-polyacrylonitrile membrane by electrospinning

[0051] (1) Preparation of silica-polyacrylonitrile

[0052] Using N,N-dimethylformamide (DMF) as a solvent for PAN polymer and silica, the SiO 2 Stir and dissolve into the PAN / DMF solution to obtain the electrospinning precursor solution, wherein DMF:PAN:SiO 2 Weigh according to the mass ratio of 8:1:0.25. Inhale the precursor solution into the syringe, and perform electrospinning with the following parameters: adjust the distance between the needle tip and the receiving cylinder to a set distance of 25cm, apply a voltage of 18kV, inject the pump at a rate of 0.3ml / h, and collect the rotating speed at 500 rpm;

[0053] (2) Pretreatment of silica-polyacrylonitrile

[0054] The silica-polyacrylonitrile obtained in step (1) was stabilized in air at 260 °C for 4 h, and the heating rate was 1 °C / min;

[0055] (3) Carbonization treatment of silica-polyacrylonitrile

[0056] The pretreated silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com