A preparation method of a positive electrode modified spacer applied in a lithium sulfur battery

A lithium-sulfur battery and positive electrode technology, which is applied in the field of preparation of positive electrode modified interlayers, can solve the problems of low utilization rate of active materials and poor performance of lithium-sulfur batteries, and achieve rich pores, good thermal stability and mechanical properties, Effect of improving absorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The first step, preparation of electrospinning precursor solution:

[0029] Under magnetic stirring state, in 20g 10% (mass percentage) polyvinyl alcohol solution, slowly dropwise add zinc acetate solution (1.5g (CH 3 COO) 2 Zn·H 2 O and 2g H 2 o). Then reflux in a water bath at 60°C for 5h for later use.

[0030] The second step, the preparation of ZnO nanofiber membrane:

[0031] Put the mixed solution into the syringe, control the working voltage to 10kV, adjust the distance between the receiver and the spinning needle to be 10cm, and the outflow rate of the solution to be 0.5ml / h, and obtain the ZnO nanofiber membrane after spinning for 6 hours.

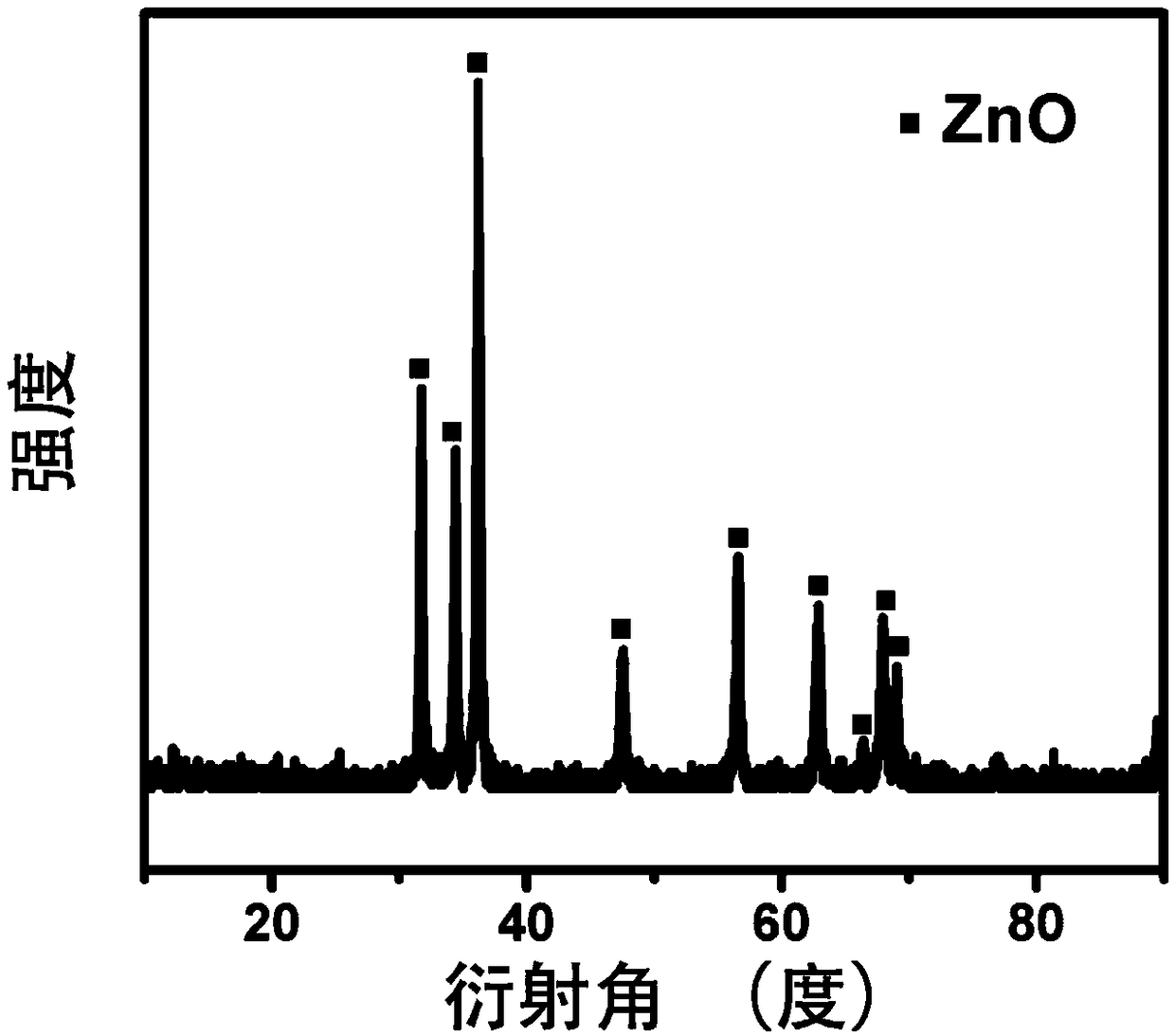

[0032] The third step, the preparation of ZnO nanofibers:

[0033] The spun fiber membrane was dried in a vacuum oven (70°C) for 8h, and then calcined at 700°C for 5h. Then cool down to room temperature naturally to get ZnO nanofibers.

[0034] The fourth step, the preparation of the positive electrode separator: ...

Embodiment 2

[0039] The first step, preparation of electrospinning precursor solution:

[0040] Under magnetic stirring state, in 20g 30% (mass percentage) polyvinyl alcohol solution, slowly dropwise add zinc acetate solution (3g (CH 3 COO) 2 Zn·H2O and 1g H 2 o). Then reflux in a water bath at 80°C for 5h for later use.

[0041] The second step, the preparation of ZnO nanofiber membrane:

[0042] Add the mixed solution into the syringe, control the working voltage to 10kV, adjust the distance between the receiver and the spinning needle to 10cm, and the outflow rate of the solution to 0.5ml / h, and obtain the ZnO nanofiber membrane after spinning for 4 hours.

[0043] The third step, the preparation of ZnO nanofibers:

[0044] The spun fibers were dried in a vacuum oven (70°C) for 8h, and then calcined at 700°C for 5h. Then cool down to room temperature naturally to get ZnO nanofibers.

[0045] The fourth step, the preparation of the positive electrode separator:

[0046] Place the...

Embodiment 3

[0048] The first step, preparation of electrospinning precursor solution:

[0049] Under magnetic stirring state, in 20g 10% (mass percentage) polyvinyl alcohol solution, slowly dropwise add zinc acetate solution (1.5g (CH 3 COO) 2 Zn·H2O and 2g H 2 o). Then reflux in a water bath at 60°C for 5h for later use.

[0050] The second step, the preparation of ZnO nanofiber membrane:

[0051] Put the mixed solution into the syringe, control the working voltage to 20kV, adjust the distance between the receiver and the spinning needle to 20cm, the outflow rate of the solution to 0.8ml / h, and the spinning time to 4~8h, to obtain the ZnO nanofiber membrane.

[0052] The third step, the preparation of ZnO nanofibers:

[0053] The spun fiber membrane was dried in a vacuum oven (70°C) for 8h, and then calcined at 700°C for 5h. Then cool down to room temperature naturally to get ZnO nanofibers.

[0054] The fourth step, the preparation of the positive electrode separator:

[0055] P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com