A method for preparing a functional barrier layer for a lithium sulfide battery

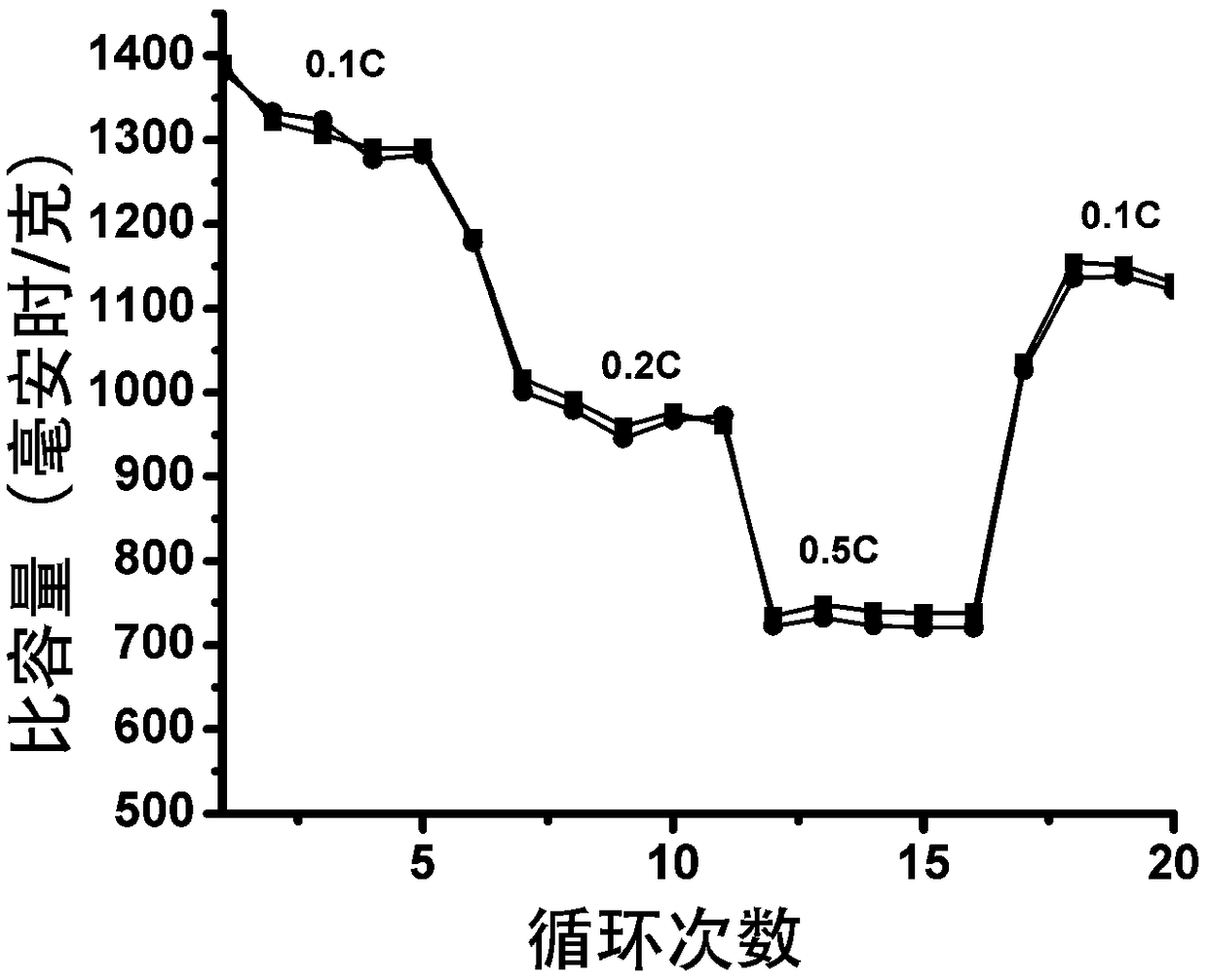

A lithium-sulfur battery and functional technology, applied in the field of preparation of functional interlayers, can solve the problems of low utilization rate of active materials and poor performance of lithium-sulfur batteries, and achieve rich pores, good thermal stability and mechanical properties, Effect of improving absorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0027] The first step, preparation of electrospinning precursor solution:

[0028] Add 0.3g Co(NO 3 ) 2 ·6H 2 O and 5ml ethanol and 5ml N,N-dimethylformamide (DMF), stirred for 20min, added 0.7g PVP to the mixed solution, stirred for 1h, and finally ultrasonicated for 1h in an ultrasonic machine to obtain the electrospinning precursor .

[0029] The second step, the preparation of metal cobalt salt nanofiber membrane:

[0030] Put the mixed solution into the syringe, control the working voltage to 20KV, adjust the distance between the receiver and the spinning needle to be 15cm, and the outflow speed of the solution to be 0.5ml / h to obtain the metal cobalt salt nanofiber membrane.

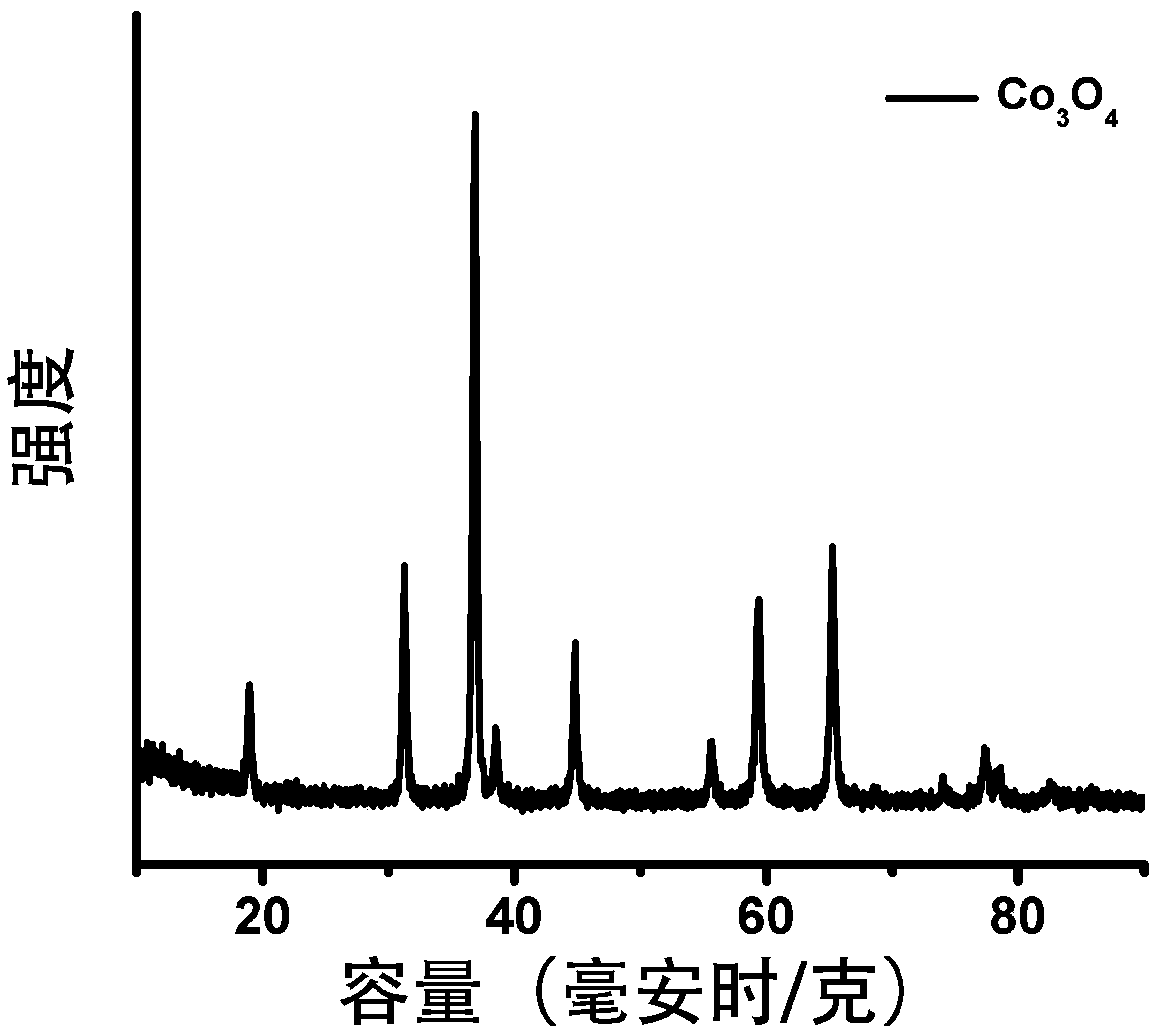

[0031] In the third step, Co 3 o 4 Preparation of nanofibers:

[0032] The spun metal cobalt salt fiber membrane was dried in a vacuum oven (70°C) for 10h, and then calcined in a muffle furnace at 500°C for 5h. Then naturally lowered to room temperature, the Co 3 o 4 Nanofibers.

[0033]...

Embodiment example 2

[0039] The first step, preparation of electrospinning precursor solution:

[0040] Add 0.3g Co(NO 3 ) 2 ·6H 2 O and 10ml ethanol and 5ml N,N-dimethylformamide (DMF), stirred for 20min, then added 1g of PVP to the mixed solution, stirred for another 2h, and finally ultrasonicated in an ultrasonic machine for 1h to obtain an electrospinning precursor.

[0041] The second step, the preparation of metal cobalt salt nanofiber membrane:

[0042] Put the mixed solution into the syringe, control the working voltage to 20KV, adjust the distance between the receiver and the spinning needle to be 15cm, and the outflow rate of the solution to be 0.5ml / h to obtain the metal salt nanofiber membrane.

[0043] In the third step, Co 3 o 4 Preparation of nanofibers:

[0044] The spun metal cobalt salt fiber membrane was dried in a vacuum oven (70°C) for 10h, and then calcined in a muffle furnace at 500°C for 5h. Then naturally lowered to room temperature, the Co 3 o 4 Nanofibers.

[0...

Embodiment example 3

[0049] The first step, preparation of electrospinning precursor solution:

[0050] Add 0.3g Co(NO 3 ) 2 ·6H 2 O and 5ml ethanol and 5ml N,N-dimethylformamide (DMF), stirred for 20min, then added 0.7g PVP to the mixed solution, stirred for 2h, and finally ultrasonicated for 1h in an ultrasonic machine to obtain an electrospinning precursor .

[0051] The second step, the preparation of metal cobalt salt nanofiber membrane:

[0052] Put the mixed solution into the syringe, control the working voltage to 10KV, adjust the distance between the receiver and the spinning needle to 25cm, and the outflow rate of the solution to 0.1ml / h to obtain the metal salt nanofiber membrane.

[0053] In the third step, Co 3 o 4 Preparation of nanofibers:

[0054] The spun metal cobalt salt fiber membrane was dried in a vacuum oven (70°C) for 10h, and then calcined in a muffle furnace at 500°C for 5h. Then naturally lowered to room temperature, the Co 3 o 4 Nanofibers.

[0055] The fourt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com