Resistant starch rice noodles and preparation method and application thereof

A technology of resistant starch and rice noodles, applied in the field of food processing, can solve problems such as low penetration rate, and achieve the effects of improving shelf life, good cooking resistance, and reducing glycemic index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

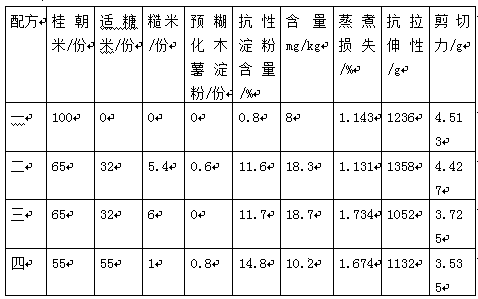

Examples

Embodiment 1

[0027] A resistant starch rice noodle is composed of the following raw materials:

[0028] 60 parts of Guichao rice, 26 parts of suitable sugar rice, 3 parts of brown rice, and 0.5 part of pregelatinized tapioca starch. The preparation method of resistant starch rice noodle, carries out according to the following steps:

[0029] (1) Ingredients, kneading noodles: Soak Guichao rice, suitable sugar rice and brown rice for 5 hours, drain the water and grind them into rice flour, pass through an 80-mesh sieve, then add pre-gelatinized tapioca starch to the rice flour, add 20% of water and make a dough ;

[0030] (2) Extrusion molding: Put the reconciled dough into the extrusion molding machine for extrusion molding;

[0031] (3) Aging and fermentation: Put the rice noodles into the aging room, control the temperature at 20°C, humidity at 60%, and time for 8 hours;

[0032] (4) Microwave sterilization or drying: semi-dry rice noodles are directly bagged, fresh and wet rice noodl...

Embodiment 2

[0034] A kind of resistant starch rice noodle, it is made up of following raw material:

[0035] 70 parts of Guichao rice, 36.5 parts of suitable sugar rice, 6 parts of brown rice, and 1 part of pregelatinized tapioca starch. The preparation method of resistant starch rice noodle, carries out according to the following steps:

[0036] (1) Ingredients, kneading noodles: Soak Guichao rice, suitable sugar rice and brown rice for 10 hours, drain the water and grind them into rice flour and pass through an 80-mesh sieve, then add pre-gelatinized tapioca starch to the rice flour, then add 40% water and ingredients dough;

[0037] (2) Extrusion molding: Put the reconciled dough into the extrusion molding machine for extrusion molding;

[0038] (3) Aging and fermentation: Put the rice noodles into the aging room, control the temperature at 35°C, humidity at 80%, and time for 16 hours;

[0039] (4) Microwave sterilization or drying: semi-dry rice noodles are directly bagged, fresh a...

Embodiment 3

[0041] Evaluation of the functional component content of the resistant starch rice noodle of the present invention:

[0042] 1. Detection of γ-aminobutyric acid (GABA) content:

[0043] (1) Weigh 500mg of the sample and grind it into a 15mL centrifuge test tube (with cover), and tap the test tube gently to make the sample fall to the bottom of the test tube; (2) Add 5mL of distilled water to each tube; (3) Put the tied Put the test tube on a reciprocating shaker (200 times / min) and take it out after hydrolysis for 2 hours; (4) take it out and centrifuge it at 10000r / min for 3 minutes; .0) 0.6mL; (6) Add 2mL of 5% phenol and 1mL of sodium hypochlorite with a mass fraction of 7%; (7) Heat in a boiling water bath for 5min after fully shaking; (8) Cool in an ice bath for 5min and shake continuously; (9) ) into 2 mL of 60% ethanol, use a spectrophotometer to measure the absorbance value at 645 nm, and determine the content of γ-aminobutyric acid by the standard curve method. Meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com