Automatic control device of welding robot

An automatic control and welding robot technology, applied in the direction of auxiliary equipment, welding equipment, welding equipment, etc., can solve the problems that the production line resources of the control device cannot be better utilized, the welding work of the mechanical arm is single, and the production cost is increased, etc., to achieve welding Good effect, high degree of automation, convenient welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

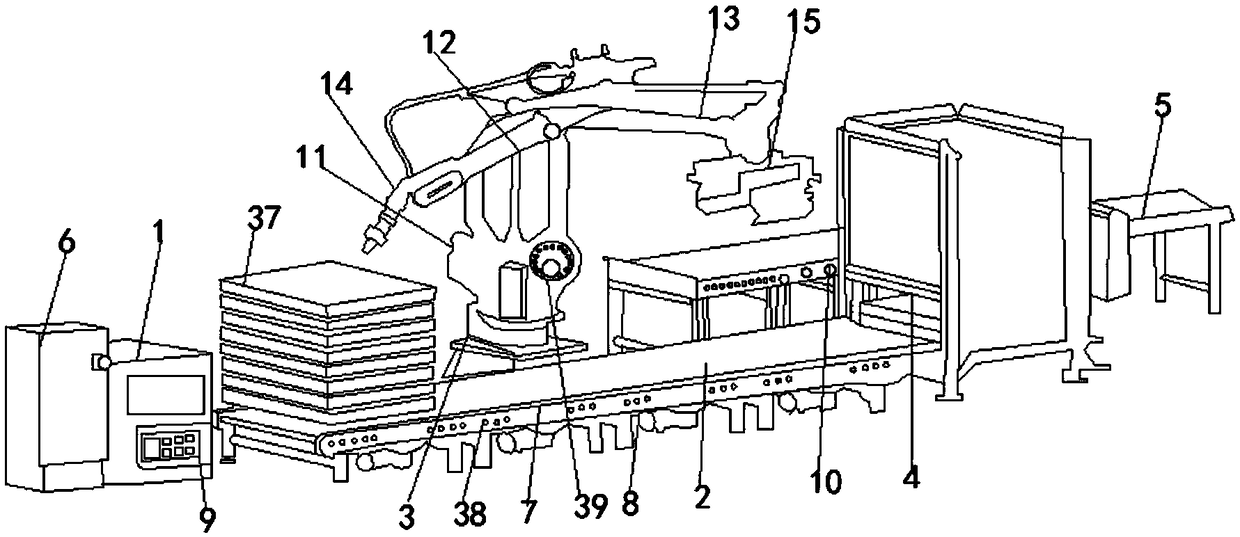

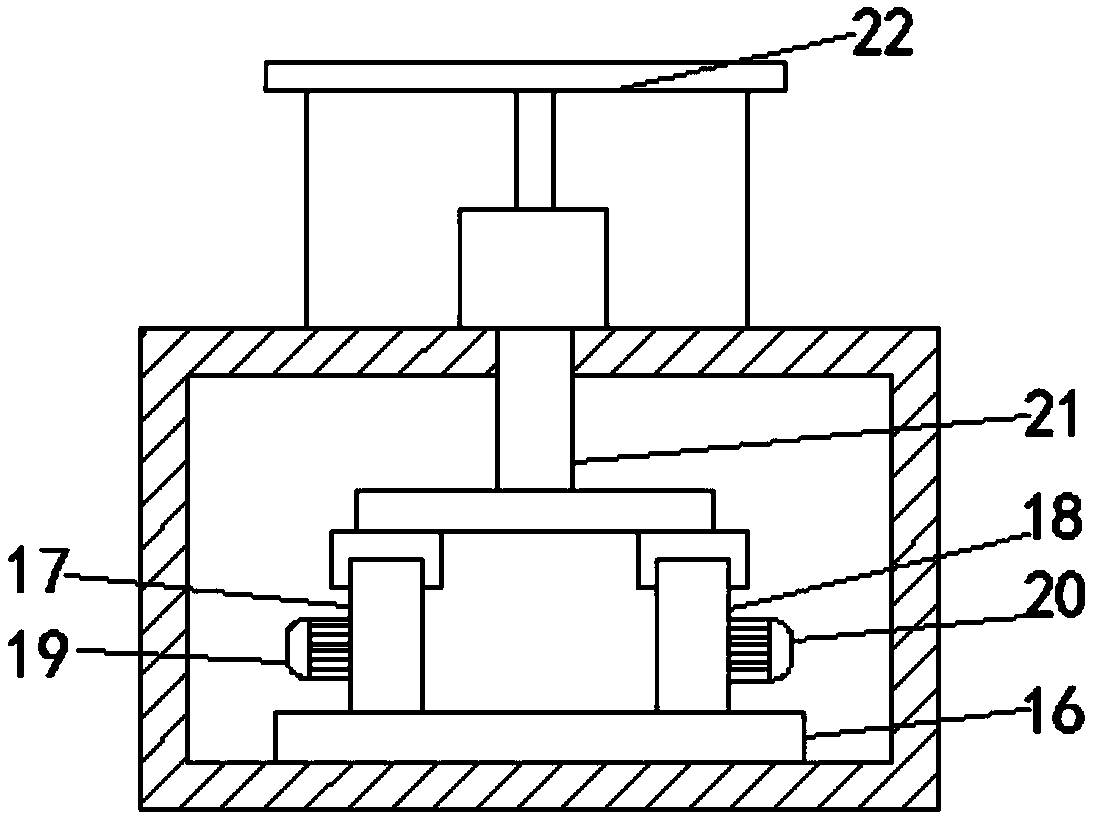

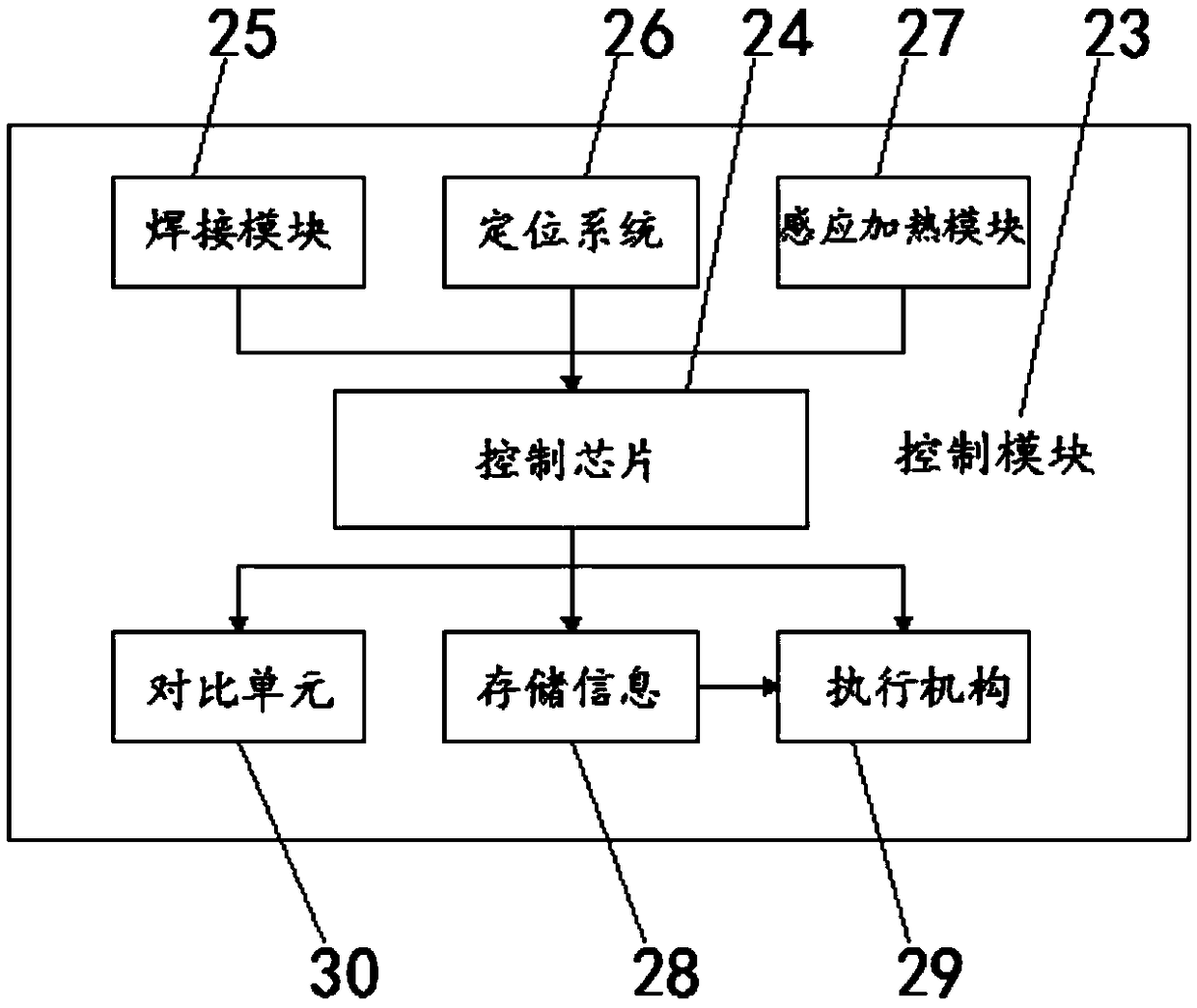

[0019] Refer to attached Figure 1-4 , an automatic control device for a welding robot, comprising a controller 1, a workbench 2, a rotating chassis 3, a storage port 4 and a winding wheel 5, one side of the controller 1 is connected to the workbench 2 through a power distribution cabinet 6 The outer wall of the workbench 2 is connected with a rectangular array of transmission rollers 7 on both sides along the edge, the bottom of the transmission roller 7 is fixedly connected with a hinge 8, and the electric control switch 9 on the controller 1 is connected to the The transmission rollers 7 are connected to each other, the storage port 4 is connected to one end of the workbench 2 away from the power distribution cabinet 6, and the inspection port 10 connected to the controller 1 is connected to one end of the storage port 4 , the top of the storage port 4 is connected with a winding wheel 5 close to the workbench 2, and the top of the rotating chassis 3 is respectively connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com