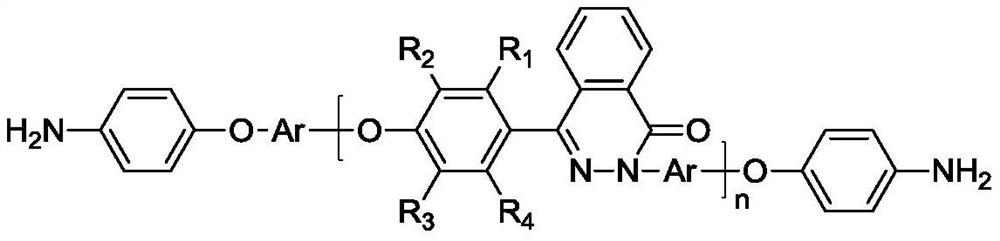

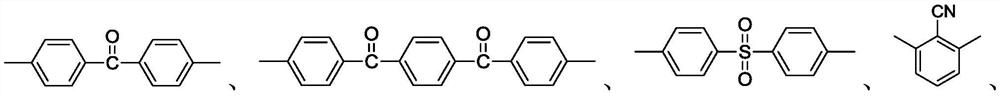

Method for preparing phthalonitrile resin cured product by amino-terminated polyarylether curing agent containing phthalazinone biphenyl structure

A technology of phthalonitrile resin and naphthalene biphenyl, which is applied in the field of material science, can solve problems such as defects, volatile or decomposed resin, etc., and achieves wide processing window, excellent melt processing fluidity, and excellent thermal stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 1g of resorcinol-based phthalonitrile resin precursor, add 0.1g of amino-terminated polyaryl ether ketone curing agent, grind it thoroughly, and put it into a reactor with a temperature of 180°C , heat and stir until completely melted, then pour the liquid mixture into a mold, and heat in a muffle furnace at 200°C / 2 hours; 250°C / 2 hours; 300°C / 2 hours; 350°C / 2 hours; 375°C / 2 hours; program curing at 400°C / 2 hours, and then cooled to room temperature to prepare isophthalonitrile resin.

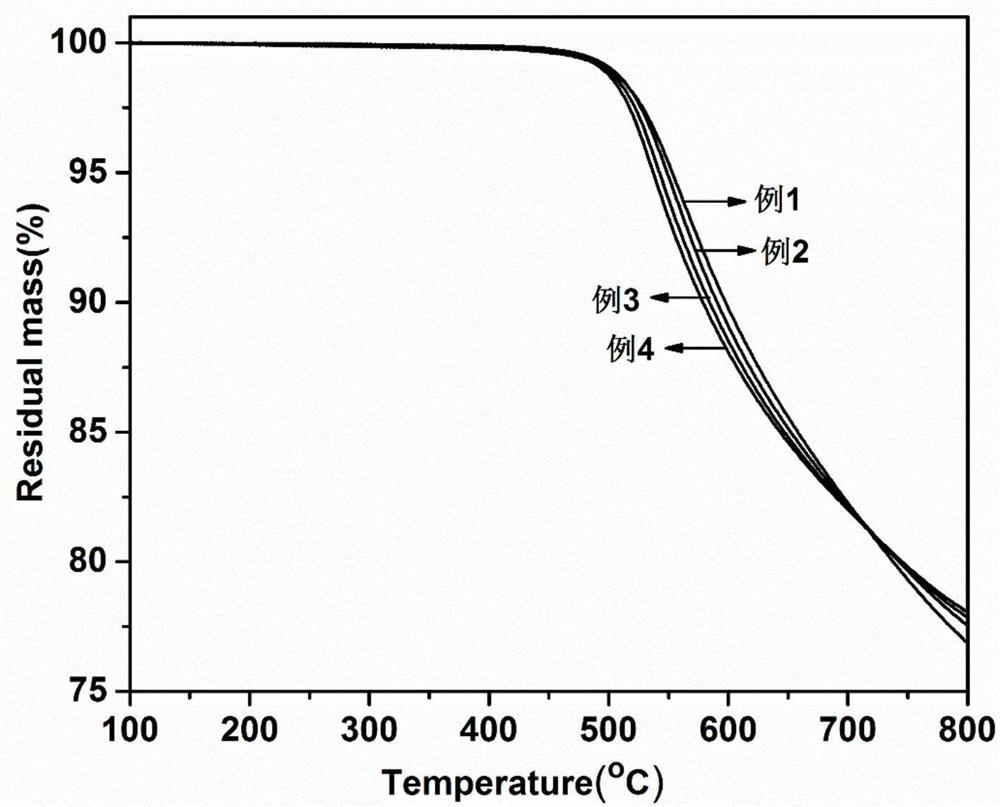

[0029] After curing, the phthalonitrile resin has a 5% thermal weight loss temperature of 553.2°C under a nitrogen atmosphere, and a carbon residue rate of 76.9% at 800°C.

[0030] Rheological analysis shows that when the temperature rises to 182.5°C, the viscosity decreases to within 50Pa·s, the lowest viscosity is 0.167Pa·s, the gel temperature is 377.1°C, and the processing temperature window is 194.6°C.

Embodiment 2

[0032] Weigh 1g of resorcinol-based phthalonitrile resin precursor, add 0.2g of amino-terminated polyaryl ether ketone curing agent, grind it thoroughly, and put it into a reactor with a temperature of 180°C , heat and stir until completely melted, then pour the liquid mixture into a mold, and heat in a muffle furnace at 200°C / 2 hours; 250°C / 2 hours; 300°C / 2 hours; 350°C / 2 hours; 375°C / 2 hours; program curing at 400°C / 2 hours, and then cooled to room temperature to prepare isophthalonitrile resin.

[0033] After curing, the phthalonitrile resin has a 5% thermal weight loss temperature of 548.8°C under a nitrogen atmosphere, and a carbon residue rate of 77.5% at 800°C.

[0034] Rheological analysis shows that when the temperature rises to 181.5°C, the viscosity decreases to within 50Pa·s, the lowest viscosity is 0.255Pa·s, the gel temperature is 279.2°C, and the processing temperature window is 97.7°C.

Embodiment 3

[0036] Weigh 1g of resorcinol-based phthalonitrile resin precursor, add 0.3g of amino-terminated naphthalene biphenyl polyaryletherketone curing agent, grind it thoroughly, and put it into a reactor with a temperature of 180°C , heat and stir until completely melted, then pour the liquid mixture into a mold, and heat in a muffle furnace at 200°C / 2 hours; 250°C / 2 hours; 300°C / 2 hours; 350°C / 2 hours; 375°C / 2 hours; program curing at 400°C / 2 hours, and then cooled to room temperature to prepare isophthalonitrile resin.

[0037] After curing, the phthalonitrile resin has a 5% thermal weight loss temperature of 542.5°C under a nitrogen atmosphere, and a carbon residue rate of 77.9% at 800°C.

[0038] Rheological analysis shows that when the temperature rises to 179.3°C, the viscosity decreases to within 50Pa·s, the minimum viscosity is 0.524Pa·s, the gel temperature is 222.8°C, and the processing temperature window is 43.5°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com