Preparation method of high-strength gel plugging agent material

The technology of a plugging agent and gel is applied in the field of preparation of high-strength gel plugging agent materials, which can solve the problems of reducing the mechanical properties of materials, poor plugging performance, easy to be diluted by running water, etc. Improve structural properties and mechanical strength, good viscoelasticity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

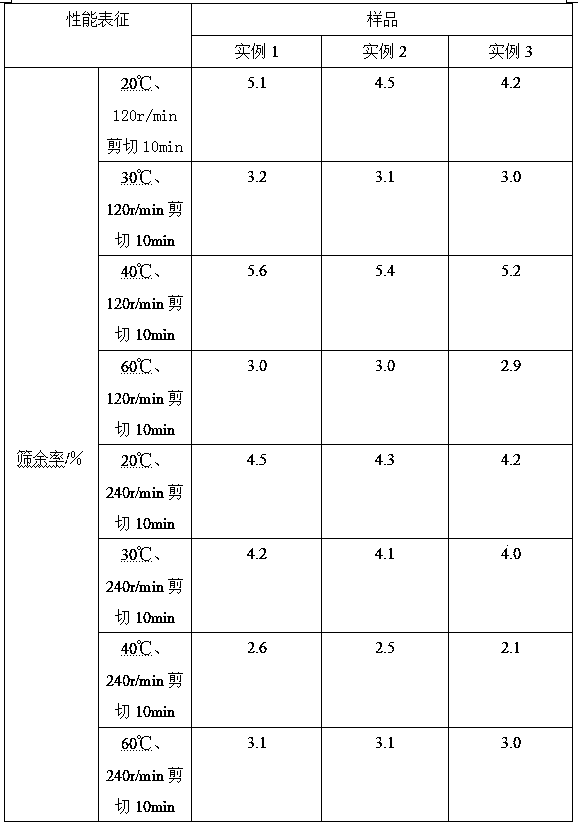

Examples

Embodiment Construction

[0018] Take the cane pith and pulverize it through a 100-mesh sieve, collect the sieved powder, add the sieved powder to a 5% sodium hydroxide solution by mass at a mass ratio of 1:10, stir and mix, and cook at 100-120 ° C for 1- 2h, stand to cool to room temperature, filter and collect the filter cake, vacuum freeze-dry and collect the dry particles, in parts by weight, weigh 45-50 parts of deionized water, 6-8 parts of dry particles, 10-15 parts of acrylic acid respectively , 6 to 8 parts of 200 mesh kaolin, 25 to 30 parts of N,N'-methylenebisacrylamide and 0.1 to 0.5 parts of ammonium persulfate were placed in a three-necked flask, stirred and mixed and adjusted with a mass fraction of 5% sodium hydroxide solution pH to 8.5, stir and mix and place in a three-necked flask, incubate the reaction at 75-80 °C for 2-3 hours, let stand to cool to room temperature, collect the reaction solution and place it in the syringe of the electrospinning device, and control the constant perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com