A composite magnetic core and a preparation method thereof

A technology of composite materials and magnetic cores, which is applied in the manufacture of magnetic cores, magnetic materials, inductors/transformers/magnets, etc., can solve the problems of low saturation magnetic induction, high brittleness, and high coercive force, and achieve high production efficiency and low Requirements, the effect of low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

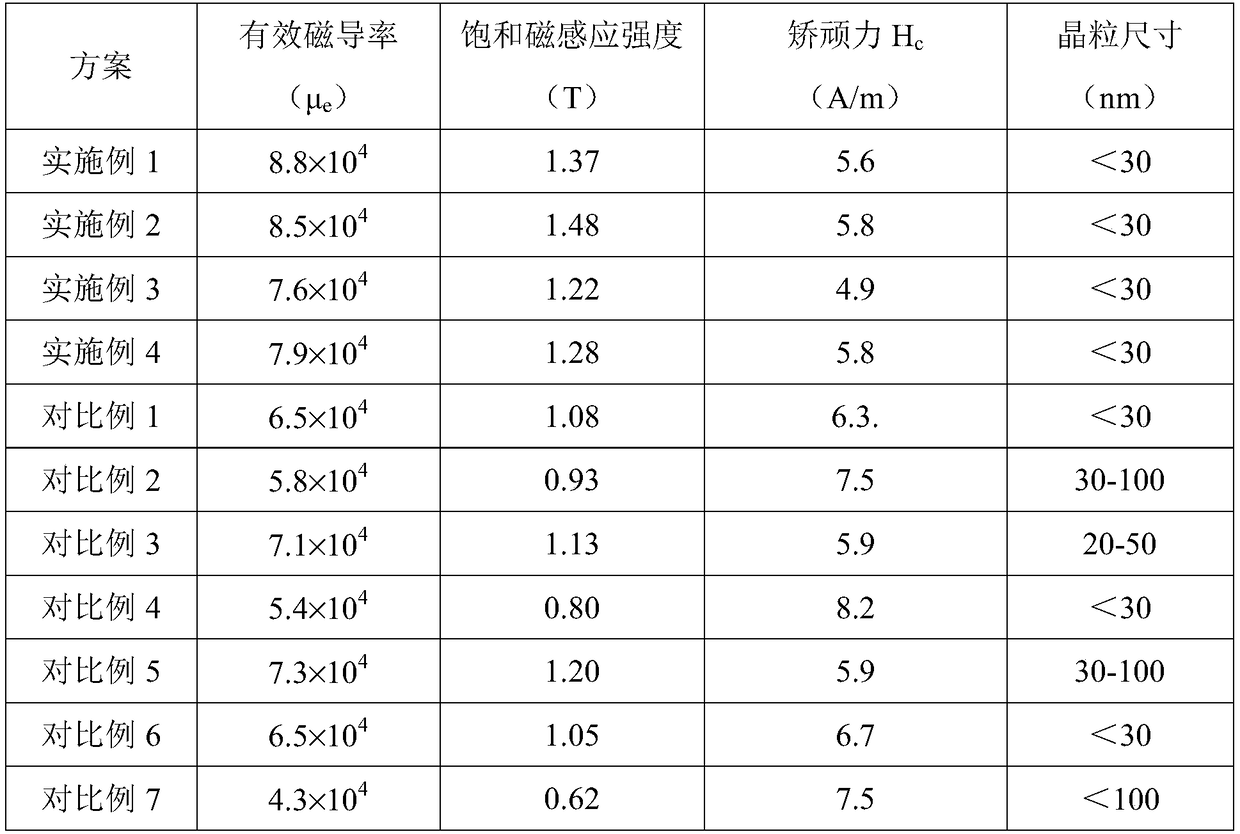

Examples

Embodiment 1

[0053] The composite magnetic core prepared in this embodiment is composed of the following components: Fe 73.8%, B 8.5%, Si 12.5%, C 0.5%, Cu 1.7%, Nb 2.5%, Mo 0.5%.

[0054] Prepare as follows:

[0055] (1) Fe, B, Si, C, Cu, Nb and Mo with a purity higher than 99.9% are used as raw materials, and the ingredients are weighed according to the formula amount, and the prepared raw materials are placed in a vacuum intermediate frequency induction melting furnace. Electromagnetic stirring was used to repeatedly smelt for 2.5 hours under gas atmosphere to obtain a master alloy with uniform composition;

[0056] (2) Put the master alloy obtained in step (1) into the smelting ladle in the rapid solidification equipment, adopt a single-roller strip-making process, and make strips at a speed of 30m / s to obtain a strip with a width of 60mm and a thickness of 20μm alloy;

[0057] (3) Wind the strip-shaped alloy obtained in step (2) into a magnetic core, place it in a heat treatment dev...

Embodiment 2

[0059] The composite magnetic core prepared in this embodiment is composed of the following components: Fe 71.5%, Co 2.5%, B 10%, Si 10%, P 1%, Cu 2.0%, Nb 2.5%, Ti 0.5%.

[0060] Prepare as follows:

[0061] (1) Fe, Co, B, Si, P, Cu, Nb and Ti with a purity higher than 99.9% are used as raw materials, and the ingredients are weighed according to the formula quantity, and the prepared raw materials are placed in a vacuum intermediate frequency induction melting furnace, Under the argon atmosphere, electromagnetic stirring is used for repeated melting for 3 hours to obtain a master alloy with uniform composition;

[0062] (2) Put the master alloy obtained in step (1) into the smelting ladle in the rapid solidification equipment, adopt a single-roller strip-making process, and make strips at a speed of 35m / s to obtain a strip with a width of 50mm and a thickness of 15μm alloy;

[0063] (3) Wind the strip-shaped alloy obtained in step (2) into a magnetic core, place it in a hea...

Embodiment 3

[0065] The composite magnetic core prepared in this embodiment is composed of the following components: 70.3% Fe, 3.7% Co, 10% B, 10% Si, 0.5% C, 0.5% Al, 1.0% Cu, 3% Nb, 0.5% Mo, Ag 0.5%.

[0066] Prepare as follows:

[0067] (1) Use Fe, Co, B, Si, C, Al, Cu, Nb, Mo and Ag with a purity higher than 99.9% as raw materials, weigh the ingredients according to the formula amount, and place the prepared raw materials in a vacuum medium frequency induction In the smelting furnace, under the argon atmosphere, electromagnetic stirring is used to repeatedly smelt for 3 hours to obtain a master alloy with uniform composition;

[0068] (2) Put the master alloy obtained in step (1) into the smelting ladle in the rapid solidification equipment, and adopt a single-roller strip-making process at a speed of 33m / s to obtain a strip with a width of 5mm and a thickness of 20μm alloy;

[0069] (3) Wind the strip-shaped alloy obtained in step (2) into a magnetic core, place it in a heat treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com