Glass-metalsealed radio-frequency connector surface treatment method

A radio frequency connector and metal sealing technology, which is used in the surface treatment of glass-to-metal sealed radio frequency connectors, and the surface treatment field of improving the insulation resistance of glass-to-metal sealed connectors, which can solve operator and environmental hazards, thermal expansion curve It can improve the anti-discoloration and corrosion resistance, avoid further corrosion, and improve the processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

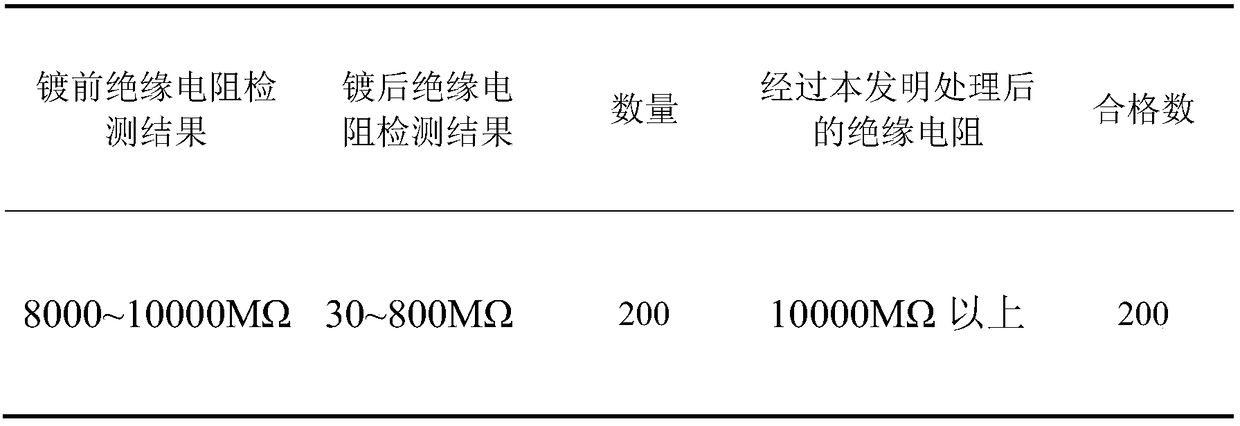

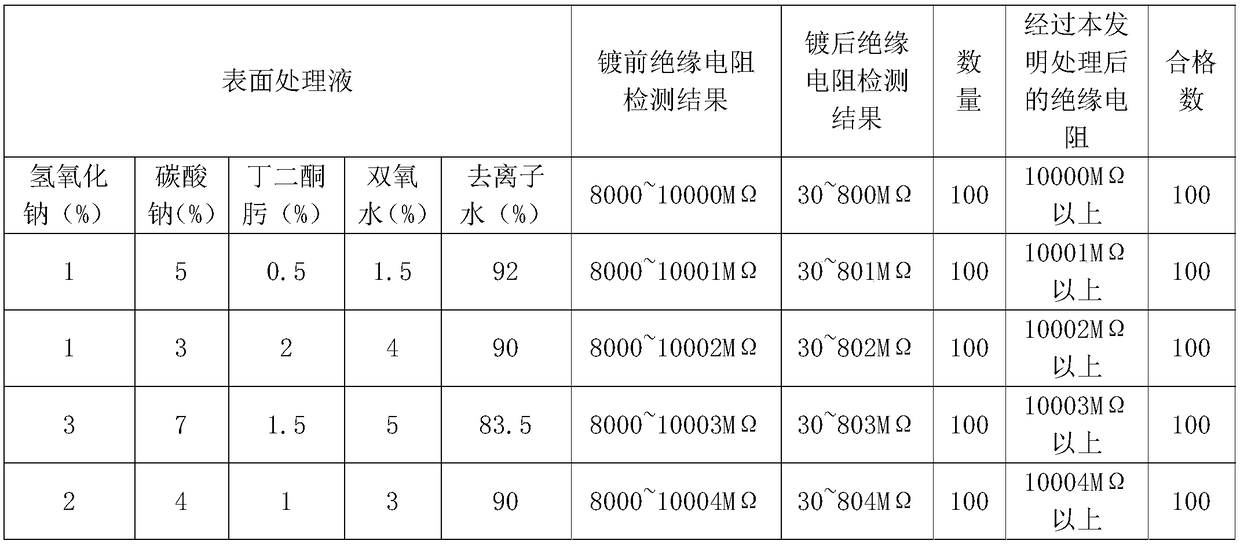

Examples

Embodiment 1

[0032] 1. In terms of mass fraction, weigh a certain amount: 1% sodium hydroxide, 4% sodium carbonate, 1.5% dimethylglyoxime, 4% hydrogen peroxide, and the balance is deionized water. The raw materials are placed in a stainless steel electric heating pot in turn, and the mixed solution is heated until the mixed solution boils;

[0033] 2. Place the glass-to-metal sealed RF connector with unqualified insulation resistance after electroplating in a net bag with a mesh number of 30, place the net bag in the mixed solution in step 1, and soak in the boiled mixed solution for 3 minutes;

[0034] 3. Use a clean beaker to measure 2L of pure water at a temperature of 60°C, place the RF connector treated in step 3) in a measuring cylinder filled with water, and then place the beaker in an ultrasonic wave for ultrasonication. The frequency of the ultrasonic wave is 70Hz, ultrasonic time 4min;

[0035]4. At room temperature, place the RF connector processed in step 4) in the alcohol sol...

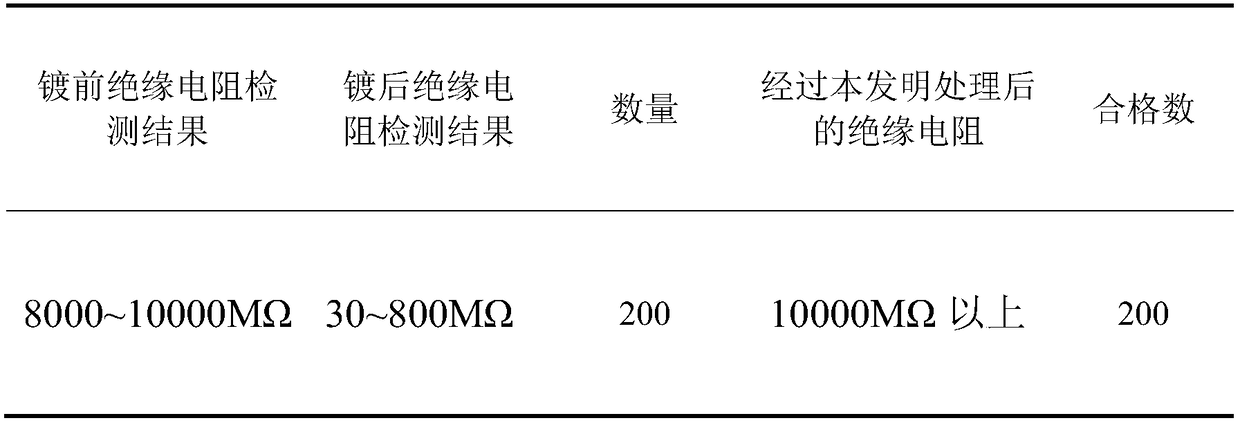

Embodiment 2

[0041] 1. In terms of mass fraction, weigh a certain amount: 1.5% sodium hydroxide, 3% sodium carbonate, 1% dimethylglyoxime, 3% hydrogen peroxide, and the balance is deionized water. Place the weighed raw materials in a stainless steel electric heating pot in turn, and heat the mixed solution until the mixed solution boils;

[0042] 2. Place the glass-to-metal sealed RF connector with unqualified insulation resistance after electroplating in a net bag with a mesh number of 20, place the net bag in the mixed solution in step 1, and soak in the boiled mixed solution for 4 minutes;

[0043] 3. Use a clean beaker to measure 1.5L of pure water at a temperature of 60°C, place the RF connector treated in step 3) in a measuring cylinder filled with water, and then place the beaker in an ultrasonic wave for ultrasonication. 80Hz, ultrasonic time 3min;

[0044] 4. At room temperature, place the RF connector processed in step 4) in an alcohol solution for ultrasonic treatment, the ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com