CsPbBr3 perovskite quantum dot-molecular imprinting fluorescence sensor for detecting omethoate and preparation method thereof

A technology of fluorescent sensor and omethoate, which is applied in the field of analytical chemistry to achieve the effects of high yield, fast reaction speed and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

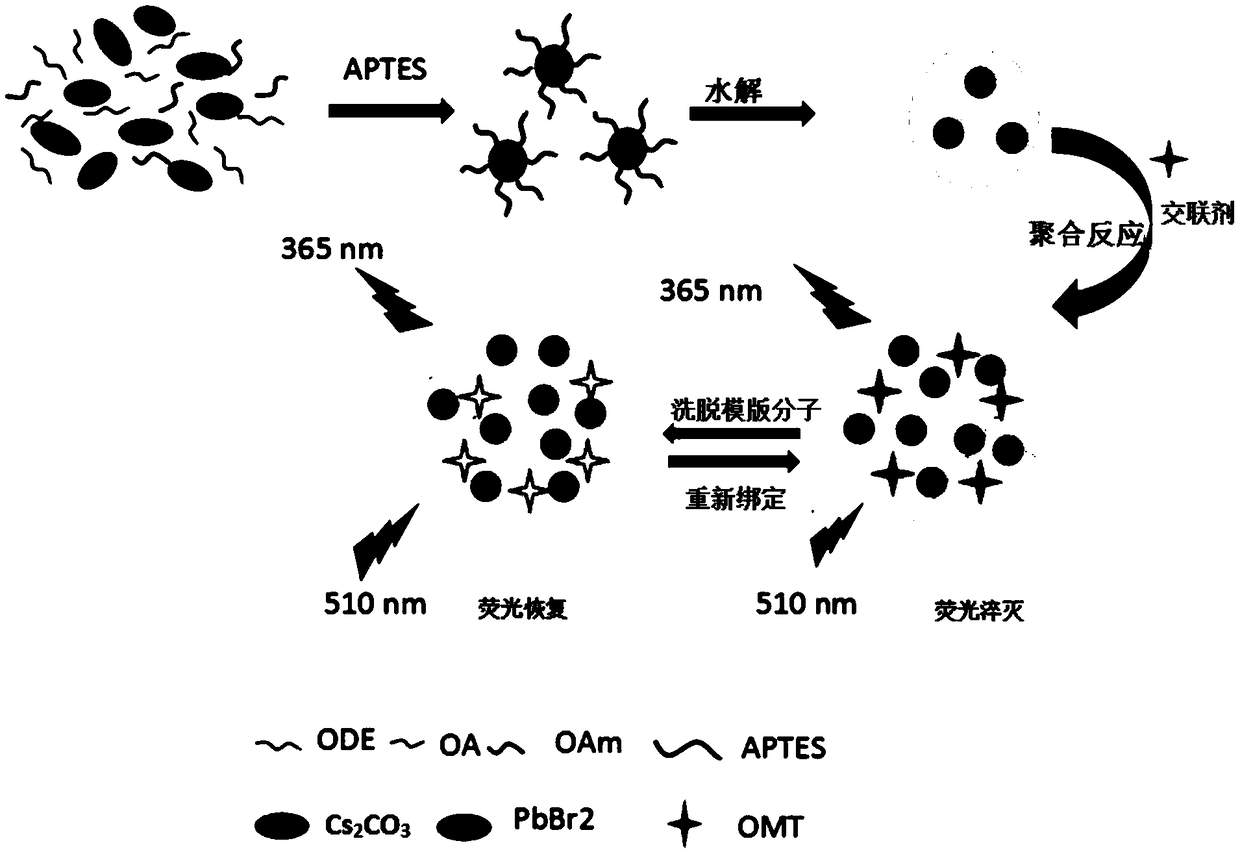

[0057] Such as figure 1 Shown, the invention provides a kind of CsPbBr for detecting omethoate 3 A method for preparing a perovskite quantum dot-molecularly imprinted fluorescent sensor, comprising the following steps:

[0058] S1: Preparation of APTES-capped CsPbBr 3 Perovskite Quantum Dots

[0059] Add 3-aminopropyltriethoxysilane (APTES) to cesium carbonate (Cs 2 CO 3 ), Octadecene (ODE), PbBr 2 , oleic acid (0A) and oleylamine (OAm) mixture, at a temperature of 20 ° C, a humidity of 40%, under air conditions, stirred for 3 hours, hydrolyzed, purified, and prepared APTES-capped CsPbBr 3 Perovskite quantum dots;

[0060] S2: Preparation of CsPbBr 3 Perovskite Quantum Dots-Molecularly Imprinted Polymers

[0061] Template molecule omethoate (OMT), octadecene, APTES-capped CsPbBr obtained in step S1 3 The perovskite quantum dots and the remaining 3-aminopropyltriethoxysilane (APTES) from the reaction in step S1 were mixed and stirred for 30 minutes, then a crosslinking...

Embodiment 1

[0068] (1) Preparation of APTES-capped CsPbBr 3 Perovskite Quantum Dots

[0069] 1) Join 0.32g cesium carbonate, 1ml oleic acid (90%, OA), 12ml octadecene (90%, ODE) in the 50ml three-neck round bottom flask, vacuum degas 10 minutes on Schlenk line, in Heating to 120°C under vacuum conditions for 1 hour, then heating to 150°C under the condition of feeding nitrogen gas, and constant temperature for 2 hours until the solution is clear to obtain a cesium oleate solution;

[0070] 2) Mix 10ml octadecene (90%, ODE) and 0.376mmol PbBr 2 Load it into a 50ml three-necked round-bottomed flask, degas it under vacuum for 10 minutes, and dry it under vacuum for 1 hour at a temperature of 120°C. , 100 μl oleylamine (80%-90%, OAm) and 1ml 3-aminopropyltriethoxysilane (APTES) were slowly added to the flask, and the solution was clarified and heated to 160°C;

[0071] 3) Preheat the cesium oleate solution prepared in step 1) to 100°C, quickly inject 1ml of the preheated cesium oleate soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com