Preparation method of hydrophobic oleophilic cochineal red pearlescent pigment

A cochineal, hydrophobic and lipophilic technology, applied in inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., can solve problems such as difficult dispersion, unevenness, agglomeration and coloring, and achieve the effect of expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

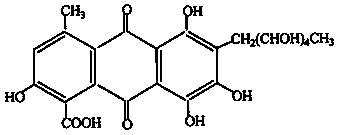

Image

Examples

Embodiment 1

[0025] A method for preparing a hydrophobic and lipophilic cochineal pearlescent pigment, using cochineal pigment and mica powder with a particle size of 10-100um as raw materials, the preparation process comprising the following steps:

[0026] Step 1: Preparation of oil-soluble cochineal pigment, adding 1 g of cochineal pigment into a mixed solution of 15 ml of acetic anhydride and 35 ml of acetic acid and stirring evenly, then adding 2 ml of triethylamine catalyst, stirring under reflux at 60° C., and reacting for 6 hours.

[0027] Step 2: Purification of oil-soluble cochineal red pigment. After the reaction, the mixed solution was cooled to room temperature, 100ml of distilled water was added, stirred for 1 hour, and then the mixed solution was distilled under reduced pressure to collect the solid product, dried in an oven at 80°C to constant weight, and the obtained product That is, oil-soluble cochineal red pigment;

[0028] Step 3: Pretreatment of mica powder, add 10g o...

Embodiment 2

[0031] A method for preparing a hydrophobic and lipophilic cochineal pearlescent pigment, using cochineal pigment and mica powder with a particle size of 10-100um as raw materials, the preparation process comprising the following steps:

[0032] Step 1: Preparation of oil-soluble cochineal pigment, adding 1g carmine to a mixed solution of 20ml acetic anhydride and 30ml acetic acid and stirring evenly, then adding 2ml triethylamine catalyst, stirring under reflux at 70°C, and reacting for 8h.

[0033] Step 2: Purification of oil-soluble carminic acid. After the reaction, cool the mixed solution to room temperature, add 100ml of distilled water, stir for 2 hours, then distill the mixed solution under reduced pressure, collect the solid product, and dry it in an oven at 80°C to constant weight. The obtained product is oil Soluble carmine;

[0034] Step 3: Pretreatment of mica powder, add 10g of mica powder to 90g of distilled water to prepare a slurry, then add 0.1g of silane cou...

Embodiment 3

[0037] A method for preparing a hydrophobic and lipophilic cochineal pearlescent pigment, using cochineal pigment and mica powder with a particle size of 10-100um as raw materials, the preparation process comprising the following steps:

[0038] Step 1: Preparation of oil-soluble cochineal pigment, adding 1g carmine to a mixed solution of 25ml acetic anhydride and 30ml acetic acid and stirring evenly, then adding 3ml triethylamine catalyst, stirring under reflux at 80°C, and reacting for 8 hours.

[0039] Step 2: Purification of oil-soluble cochineal red pigment. After the reaction, the mixed solution was cooled to room temperature, 100ml of distilled water was added, stirred for 2 hours, and then the mixed solution was distilled under reduced pressure, and the solid product was collected, dried in an oven at 80°C to constant weight, and the obtained product That is, oil-soluble cochineal red pigment;

[0040] Step 3: Pretreatment of mica powder, add 10g of mica powder to 90g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com