Weather-resistant environmentally-friendly water-based metal anticorrosive coating

A metal anti-corrosion and coating technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of high environmental hazards to human body, shortened lifespan, etc., and achieve fast recoating, good weather resistance, and strong UV resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

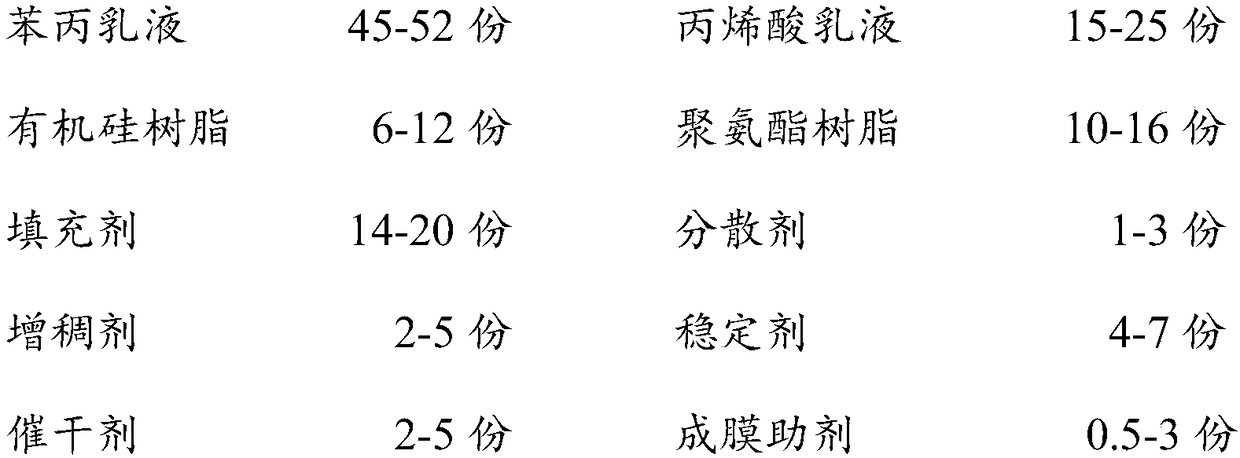

[0025] Weather-resistant and environmentally friendly water-based metal anti-corrosion coatings, the raw material components in parts by mass are:

[0026]

[0027] Its preparation method is:

[0028] Weigh the components of styrene-acrylic emulsion, acrylic emulsion, silicone resin, polyurethane resin, aluminum oxide powder, sodium tripolyphosphate, hydroxypropyl methylcellulose, castor oil derivatives, drier, propylene glycol butyl ether and water ;

[0029] Alumina powder, sodium tripolyphosphate, hydroxypropyl methylcellulose, castor oil derivatives, drier and propylene glycol butyl ether were placed in a grinder for grinding and dispersion, and the particles were controlled at 20 μm;

[0030] Add water to the reaction kettle, add silicone resin and polyurethane resin in sequence, turn on the stirrer, and stir at a speed of 80r / min until completely dissolved;

[0031] Add the styrene-acrylic emulsion and acrylic emulsion into the reaction kettle, adjust the stirring s...

Embodiment 2

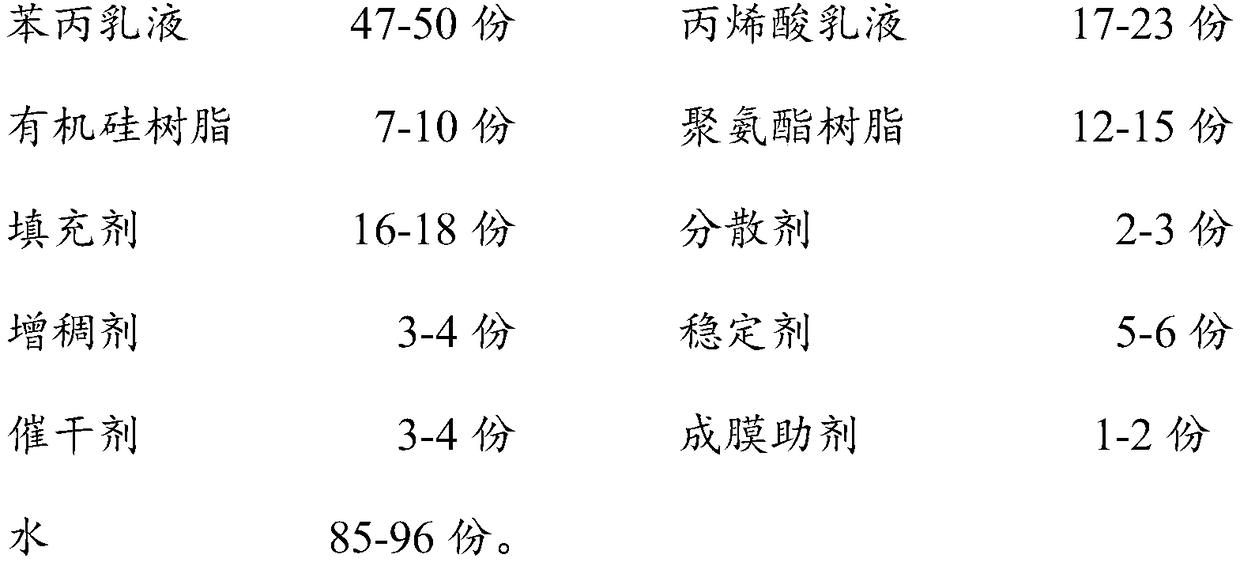

[0037] Weather-resistant and environmentally friendly water-based metal anti-corrosion coatings, the raw material components in parts by mass are:

[0038]

[0039] Its preparation method is:

[0040] Weigh the components of styrene-acrylic emulsion, acrylic emulsion, silicone resin, polyurethane resin, mica powder, sodium hexametaphosphate, sodium carboxymethylcellulose, fumed silica, cerium isooctanoate, propylene glycol methyl ether acetate and water ;

[0041] Place mica powder, sodium hexametaphosphate, sodium carboxymethylcellulose, fumed silica, cerium isooctanoate and propylene glycol methyl ether acetate in a grinder for grinding and dispersion, and the particle size is controlled at 28 μm;

[0042] Add water to the reaction kettle, add silicone resin and polyurethane resin in sequence, turn on the stirrer, and stir at a speed of 90r / min until completely dissolved;

[0043] Add the styrene-acrylic emulsion and acrylic emulsion into the reaction kettle, adjust the...

Embodiment 3

[0049] Weather-resistant and environmentally friendly water-based metal anti-corrosion coatings, the raw material components in parts by mass are:

[0050]

[0051] Its preparation method is:

[0052] Weighing component amounts of styrene-acrylic emulsion, acrylic emulsion, silicone resin, polyurethane resin, quartz powder, sodium pyrophosphate, polyacrylamide, castor oil derivatives, cerium isooctanoate, propylene glycol butyl ether and water;

[0053] Quartz powder, sodium pyrophosphate, polyacrylamide, castor oil derivatives, cerium isooctanoate and propylene glycol butyl ether were placed in a grinder for grinding and dispersion, and the particles were controlled at 30 μm;

[0054] Add water to the reaction kettle, add silicone resin and polyurethane resin in sequence, turn on the stirrer, and stir at a speed of 150r / min until completely dissolved;

[0055] Add the styrene-acrylic emulsion and acrylic emulsion into the reaction kettle, adjust the stirring speed to 200r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com