Polymeric environmentally-friendly waterproof polyurethane coating for waterproof parts of buildings

A polyurethane waterproof and building waterproof technology, applied in the field of coatings, can solve problems such as air pollution, achieve the effects of lowering roof and indoor temperature, excellent physical and mechanical properties, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

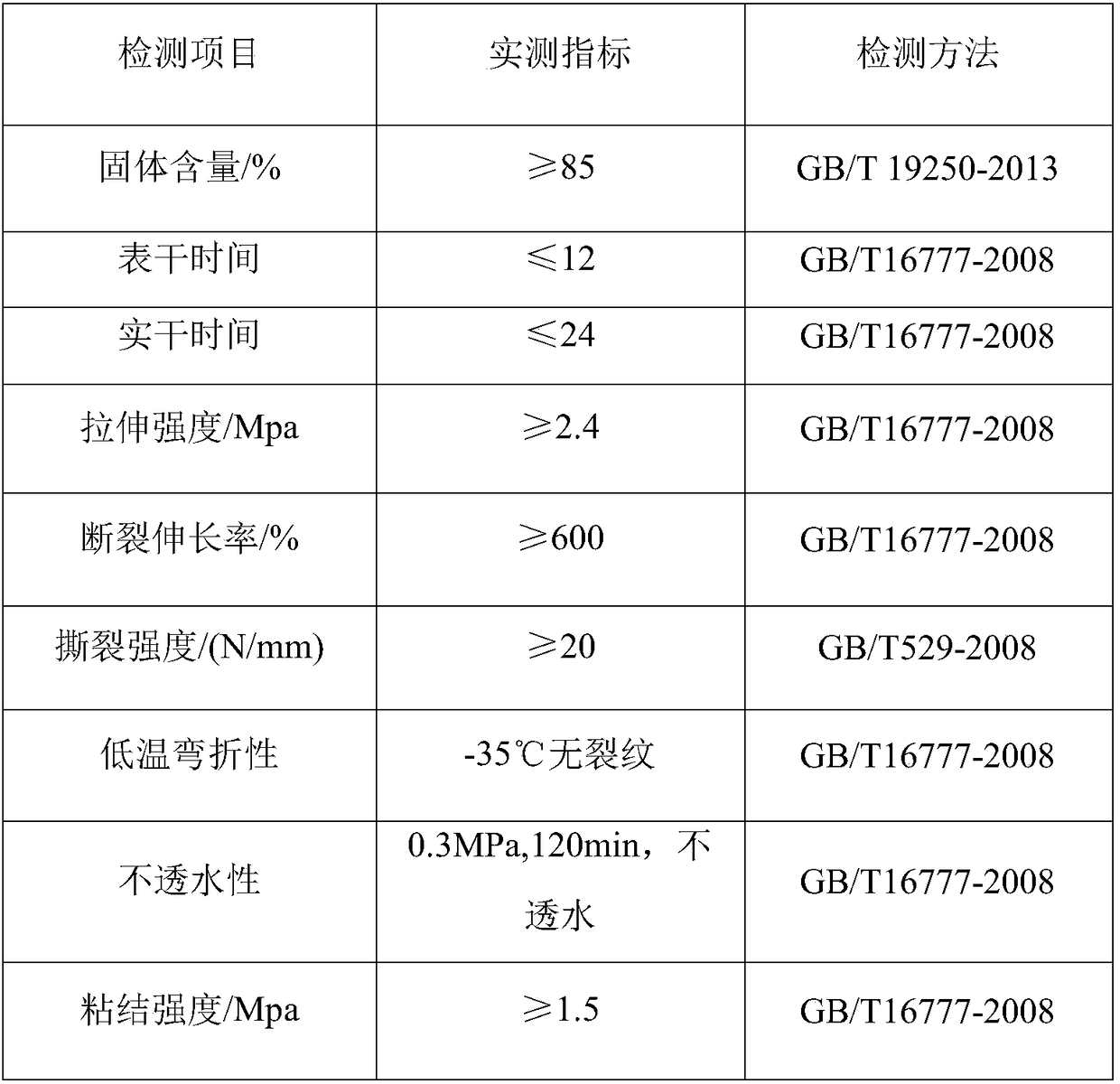

Image

Examples

Embodiment 1

[0025] By weight, 15 parts of polyether 2000N, 10 parts of polyether 330N, 1 part of liquid modifier, 0.2 parts of dispersant, 0.2 parts of defoamer, 20 parts of talcum powder, 5 parts of kaolin, 15 parts of heavy calcium, nano TiO 2 Add 5 parts into a closed reaction kettle, mix and heat through high-speed stirring, dehydrate under reduced pressure at 120°C and 0.06Mpa for 180min, make the moisture content in the reaction kettle ≤0.02%, cool down to 75°C-80°C, add 4 parts of MDI , react at constant temperature at 80°C for 120 minutes, add 0.06 parts of catalyst, and stop the reaction after 60 minutes of reaction. After the reaction, add 1 part of latent curing agent, 0.2 parts of antioxidant and 1 part of anti-settling agent under high-speed stirring state, and keep warm Stir for 60 minutes, and finally drop to below 40°C and discharge.

Embodiment 2

[0027] 20 parts of polyether 2000N, 10 parts of polyether 330N, 5 parts of liquid modifier, 0.5 parts of dispersant, 0.5 parts of defoamer, 25 parts of talc, 8 parts of kaolin, 17 parts of heavy calcium, nano-TiO 2 Add 8 parts into a closed reaction kettle, mix and heat through high-speed stirring, dehydrate under reduced pressure at 120°C and 0.06Mpa for 180min, make the moisture content in the reaction kettle ≤0.02%, cool down to 75°C-80°C, and add 6 parts of MDI React at a constant temperature of 80°C for 120 minutes, add 0.1 parts of catalyst, and stop the reaction after 60 minutes of reaction. After the reaction, add 1.5 parts of latent curing agent, 0.5 parts of antioxidant, and 2 parts of anti-settling agent under high-speed stirring, and keep stirring 60min, finally lowered to below 40°C and discharged.

Embodiment 3

[0029] 17 parts of polyether 2000N, 8 parts of polyether 330N, 3 parts of liquid modifier, 0.4 parts of dispersant, 0.3 parts of defoamer, 22 parts of talc, 6 parts of kaolin, 16 parts of heavy calcium, nano-TiO 2 Add 7 parts into a closed reaction kettle, mix and heat through high-speed stirring, dehydrate under reduced pressure at 120°C and 0.06Mpa for 180min, make the moisture content in the reaction kettle ≤0.02%, cool down to 75°C-80°C, and add 5 parts of MDI , react at a constant temperature at 80°C for 120 minutes, add 0.08 parts of catalyst, and stop the reaction after 60 minutes of reaction. After the reaction, add 1.2 parts of latent curing agent, 0.4 parts of antioxidant, and 1.5 parts of anti-settling agent under high-speed stirring, and keep warm Stir for 60 minutes, and finally drop to below 40°C and discharge.

[0030] The construction process is as follows:

[0031] Grassroots treatment --- brushing the primary treatment agent --- additional layer constructio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com