Medical implanted degradable composite bar and preparing method thereof

A technology of composite rods and magnesium alloys, applied in pharmaceutical formulations, medical science, coatings, etc., can solve problems such as atrophy, non-degradable, and natural bone function degradation, and achieve good mechanical properties, good biocompatibility, and bonding strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

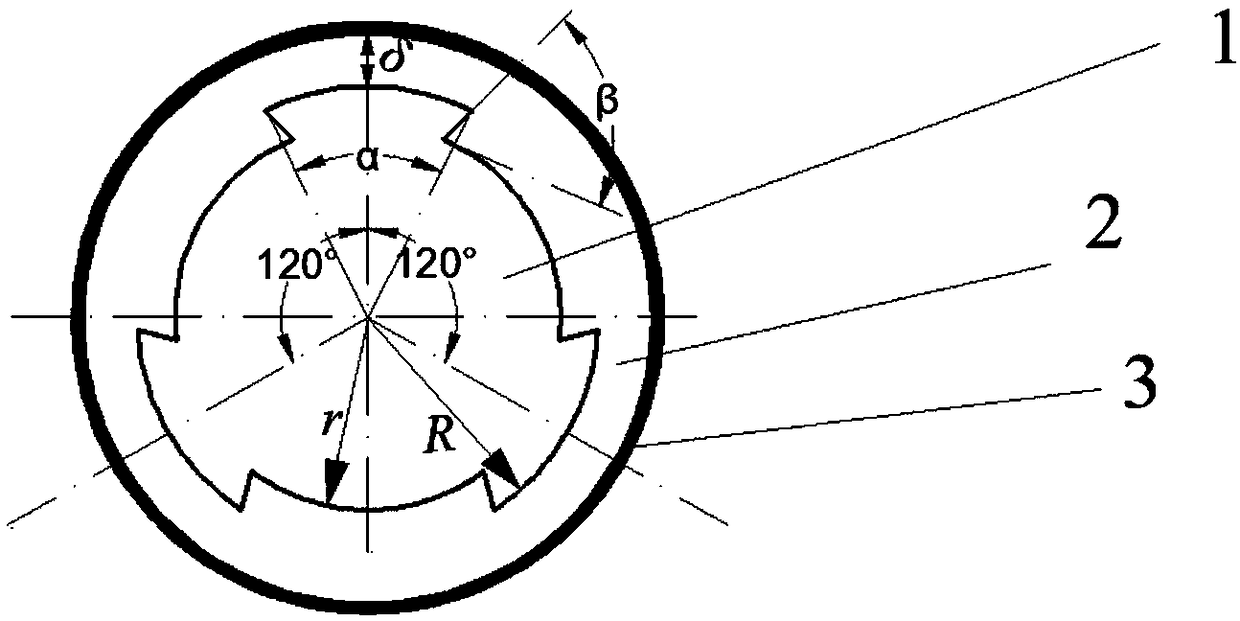

Image

Examples

Embodiment 1

[0038] (1) Preparing magnesium alloy rods, including the following steps:

[0039] 1) Alloy ingredients: The chemical composition is calculated by mass percentage: CaO 8%, Zn 6%, Sr 3%, Ce 1.0%, and the rest is Mg;

[0040] 2) Put the prepared raw materials into the non-consumable electrode water-cooled copper crucible electric arc furnace, and evacuate the furnace to 8.5×10 -4 Pa, the argon gas with a purity of 99.99% was introduced for 3 times of repeated gas scrubbing, and then smelted by electricity (temperature 1750°C, holding time 60min) and cast into ingots, then the ingots were turned over 180° and remelted 5 times to ensure the uniformity of components ;

[0041] 3) The ingot is subjected to homogenization treatment. The homogenization treatment is held at 380°C for 3 hours; then the temperature is raised to 420°C for 5 hours, and then the furnace is cooled to room temperature to obtain an ingot;

[0042]4) Heat the ingot at 400°C for 35 minutes, then carry out high...

Embodiment 2

[0064] (1) Preparing magnesium alloy rods, including the following steps:

[0065] 1) Alloy ingredients: The chemical composition is calculated by mass percentage: CaO 8.5%, Zn 7%, Sr 4%, Ce 1.2%, and the rest is Mg;

[0066] 2) Put the prepared raw materials into the non-consumable electrode water-cooled copper crucible electric arc furnace, and evacuate the furnace to 8.5×10 -4 Pa, the argon gas with a purity of 99.99% was introduced for 3 times of repeated gas scrubbing, and then smelted by electricity (temperature 1750°C, holding time 60min) and cast into ingots, then the ingots were turned over 180° and remelted 5 times to ensure the uniformity of components ;

[0067] 3) The ingot is subjected to homogenization treatment. The homogenization treatment is carried out at 380°C for 3 hours, then heated to 420°C for 5 hours, and then furnace cooled to room temperature to obtain an ingot;

[0068] 4) Heat the ingot at 400°C for 35 minutes, then carry out high-temperature pla...

Embodiment 3

[0090] (1) Preparing magnesium alloy rods, including the following steps:

[0091] 1) Alloy ingredients: The chemical composition is calculated by mass percentage: CaO 9%, Zn 8%, Sr 4.5%, Ce 1.1%, and the rest is Mg;

[0092] 2) Put the prepared raw materials into the non-consumable electrode water-cooled copper crucible electric arc furnace, and evacuate the furnace to 8.5×10 -4 Pa, the argon gas with a purity of 99.99% was introduced for 3 times of repeated gas scrubbing, and then smelted by electricity (temperature 1750°C, holding time 60min) and cast into ingots, then the ingots were turned over 180° and remelted 5 times to ensure the uniformity of components ;

[0093] 3) The ingot is subjected to homogenization treatment. The homogenization treatment is held at 380°C for 3 hours; then the temperature is raised to 420°C for 5 hours, and then the furnace is cooled to room temperature to obtain an ingot;

[0094] 4) Heat the ingot at 400°C for 35 minutes, then carry out h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com