Wearable steel ball for producing ore pulp in mine, and preparation method thereof

A technology of wear-resistant steel and slurry, which is applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problems of not meeting the performance of slurry in mine operations, improve hardenability and surface hardness, promote hardenability, improve The effect of hardenability and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of wear-resistant steel balls for producing ore pulp in mines of the present invention comprises the following process steps:

[0027] A. Molten steel smelting: Put molten iron, high-quality steel scrap and low-phosphorus-sulfur pig iron into a 120-ton LD converter for conventional top-bottom composite blowing, respectively at 25.0-30.0kg / t 钢 , 20.0~25.0kg / t 钢 , 1.0~2.0kg / t 钢 Adding lime, lightly burned dolomite and magnesite balls to make slag, controlling the carbon content at the end point ≥0.10wt%, tapping temperature ≤1640°C; adding active lime to the bottom of the ladle before tapping for slag washing, the amount of lime added 2.5kg / t 钢 ;The whole process of bottom blowing argon is adopted when tapping, and the flow rate of argon is controlled at 15-20NL / min;

[0028] B. Deoxidation alloying: Tap out the molten steel smelted in step A. When the amount of molten steel in the ladle is greater than 1 / 4, follow the following deoxidation alloy...

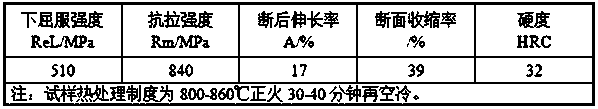

Embodiment 1

[0053] A, molten steel smelting: molten iron (chemical composition C 4.0wt%, Si 0.20wt%, Mn 0.40wt%, P 0.080wt%, S0.020wt%, the rest is Fe and unavoidable impurities), high-quality steel scrap ( Chemical composition C 0.16wt%, Si 0.12wt%, Mn 0.45wt%, P 0.015wt%, S 0.018wt%, the rest is Fe and unavoidable impurities) and low phosphorus sulfur pig iron (chemical composition C 3.2wt% , Si 0.30 wt%, Mn 0.30wt%, P 0.070wt%, S 0.020wt%, the rest are Fe and unavoidable impurities) into a 120-ton LD converter for conventional top-bottom compound blowing, respectively according to 25.0 kg / t 钢 、20.0kg / t 钢 、1.0kg / t 钢 Adding lime, lightly burned dolomite and magnesite balls to make slag, controlling the C content at the end point to 0.13wt%, and tapping temperature at 1630°C; before tapping, add active lime to the bottom of the ladle for slag washing, and the amount of lime added is 2.5kg / t 钢 ; The whole process of bottom blowing argon is adopted when tapping, and the flow rate of arg...

Embodiment 2

[0070] A, molten steel smelting: molten iron (chemical composition C 4.3wt%, Si 0.30wt%, Mn 0.58wt%, P 0.100 wt%, S0.032wt%, the rest is Fe and unavoidable impurities), high-quality steel scrap ( Chemical composition C 0.20wt%, Si 0.18wt%, Mn 0.58wt%, P 0.026wt%, S 0.027wt%, the rest is Fe and unavoidable impurities) and low phosphorus sulfur pig iron (chemical composition C 3.3wt% , Si 0.40wt%, Mn 0.40wt%, P 0.080wt%, S 0.027wt%, and the rest are Fe and unavoidable impurities) into a 120-ton LD converter for conventional top-bottom composite blowing, respectively according to 27.0 kg / t 钢 、22.0kg / t 钢 、1.6kg / t 钢 Adding lime, lightly burned dolomite and magnesite balls to make slag, controlling the end point C content to 0.12wt%, and tapping temperature at 1635°C; before tapping, add active lime to the bottom of the ladle for slag washing, and the amount of lime added is 2.5 kg / t 钢 ; The whole process of bottom blowing argon is adopted when tapping, and the flow rate of argo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com