Mask blank, mask assembly, display panel and display device

A mask substrate and display panel technology, which is applied to electrical components, electrical solid-state devices, semiconductor devices, etc., can solve the problems of circular edge color mixing, affecting product evaporation yield and production capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following describes the embodiments of the present invention in detail, and those skilled in the art will understand that the following embodiments are intended to explain the present invention, and should not be regarded as limiting the present invention. Unless otherwise specified, those skilled in the art can carry out according to commonly used techniques or conditions in this field or according to the product specification if no specific technique or condition is explicitly described in the following examples.

[0050] In one aspect of the invention, the invention provides a mask blank.

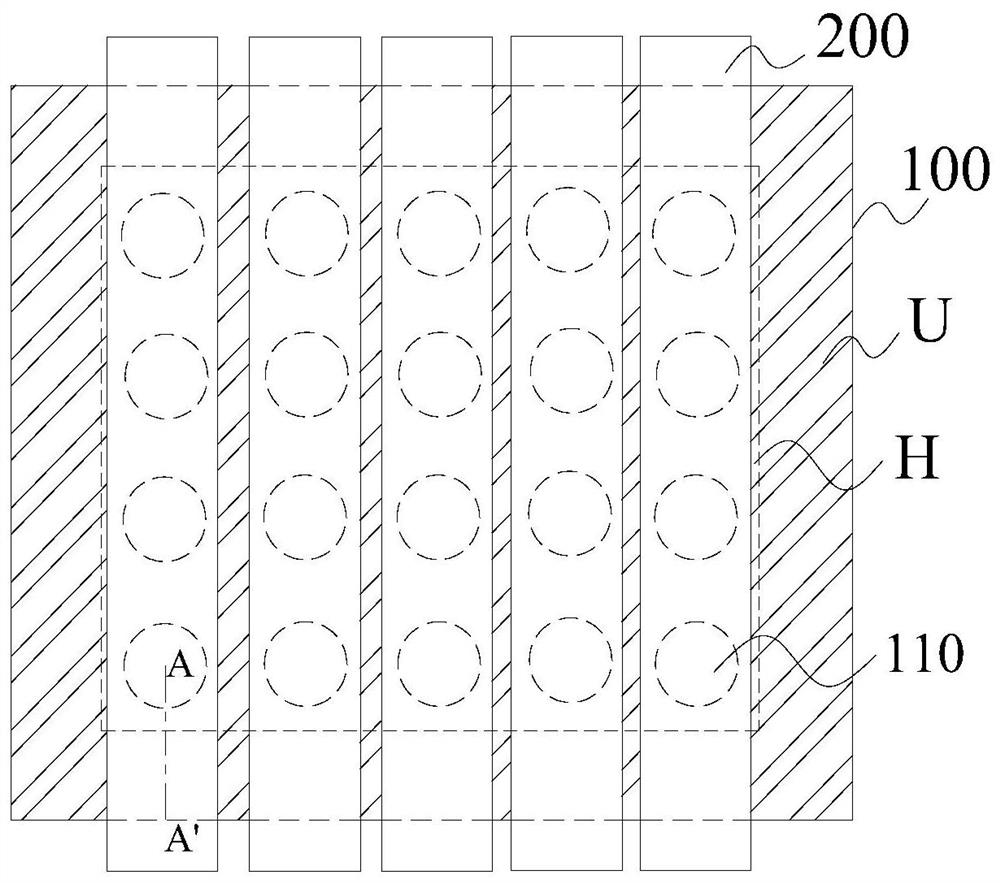

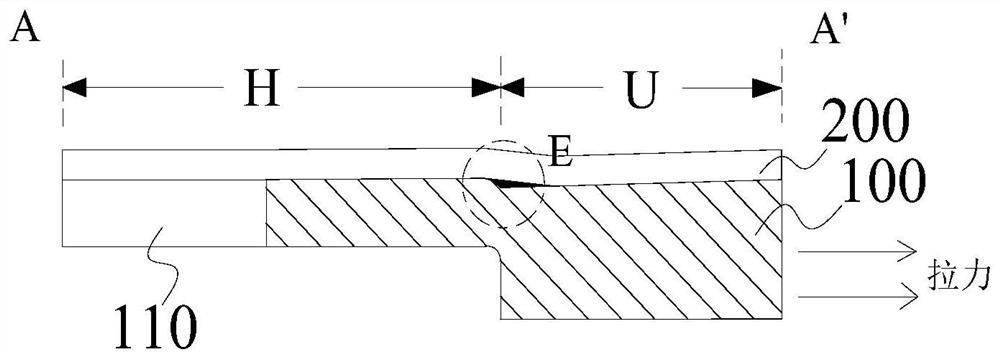

[0051] According to an embodiment of the present invention, refer to Figure 4~5, the mask substrate 100 includes a half-etched region H and a non-etched region U, the non-etched region U is arranged around the half-etched region H, and the half-etched region H has a plurality of openings 110 distributed in an array, and any one The minimum distance d′ from the opening 110 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com