Isothermal forging die laser repair method

A technology of isothermal forging and laser repair, which is used in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc. The effect of preventing overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

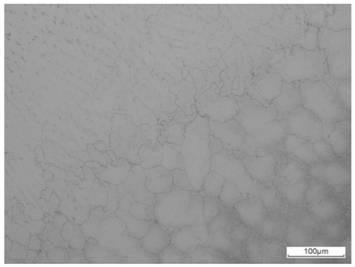

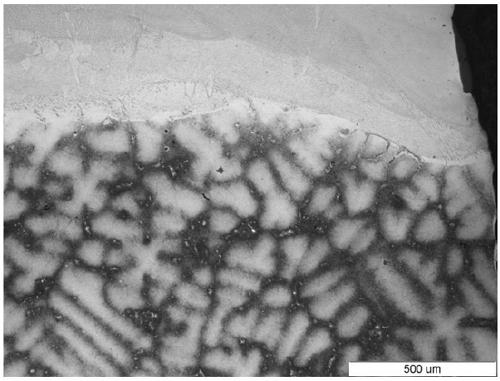

[0040] The main mass percentages of superalloy materials for isothermal forging are C 0.14%, Cr 11.5%, Co5.2%, W 5.3%, Mo 4.2%, Al 5.3%, Ti 2.6%, Fe 0.5%, a small amount of traces and impurities elements, and the rest are Ni. The defects in the above-mentioned molds are in the form of cracks, and the steps of laser repair are as follows: use mechanical methods to dig out the defects to form a groove with an opening of 90°; use acetone to treat all surfaces of the groove, including the edge of the top of the groove. Thorough cleaning to remove stains on the surface; use oxygen-acetylene flame to preheat the groove, use infrared induction thermometer to measure the preheating temperature, stop heating when the preheating temperature reaches 900 °C; use laser repair method to repair the groove The laser power is 1Kw, the laser scanning speed is 200mm / min, the spot diameter is 1.0mm, the powder feeding rate is 10g / min, the overlap rate is 50%, and the laser is suspended when the h...

Embodiment 2

[0042]The main mass percentages of superalloy materials for isothermal forging are C 0.12%, Cr 11.0%, Co5.3%, W 5.2%, Mo 4.4%, Al 5.7%, Ti 2.7%, Fe 0.4%, a small amount of traces and impurities elements, and the rest are Ni. The above-mentioned defects in the mold are in the form of cracks, and the steps of laser repair are as follows: use mechanical methods to dig out the defects to form a groove with an opening of 120°; use alcohol to clean all the surfaces of the groove, including the edge of the top of the groove. Thoroughly clean to remove the stains on the surface; use oxygen-acetylene flame to preheat the groove, use infrared induction thermometer to measure the preheating temperature, stop heating when the preheating temperature exceeds 800 ℃; use laser repair method to repair the groove The laser power is 6Kw, the laser scanning speed is 300mm / min, the spot diameter is 3.0mm, the powder feeding rate is 30g / min, the overlap rate is 50%, and the laser is suspended when ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com