High pullout strength building reinforced polyacrylonitrile short-cut fiber, preparation method and applications thereof

A technology of chopped fiber and polyacrylonitrile is applied in the field of building reinforced polyacrylonitrile chopped fiber and its preparation, which can solve the problems of poor compression resistance and the like, and achieve the effect of improving compression resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Stock solution preparation: Refined acrylonitrile, sodium methacryl sulfonate, methyl acrylate in mass ratio 99.6:0.2:0.2, solid content 15%, azobisisobutyronitrile accounted for 0.2wt% of comonomer, with Add dimethyl sulfoxide as a solvent into the reactor, and react at a constant temperature of 50° C. for 20 hours under the protection of nitrogen to obtain a polymerization stock solution with an intrinsic viscosity of 3.2 dL / g. After "vacuum-nitrogen" replacement, single removal, vacuum defoaming, and 2 micron precision filtration, the spinning stock solution is prepared.

[0045] 2. Coagulation forming: The primary fiber is prepared by wet spinning. The spinning stock solution is accurately metered by a metering pump and filtered again, and then enters the first coagulation bath through the spinneret. The coagulation temperature is 25°C and the concentration is 50%. The draw ratio is -20%, followed by two-stage coagulation and drawing, and the draw ratios are resp...

Embodiment 2

[0053] 1. Stock solution preparation: same as Step 1 of Example 1.

[0054] 2. Solidification molding: same as step 2 of embodiment 1.

[0055] 3. Drawing and washing: same as Step 3 of Example 1.

[0056] 4. One-time oiling and drying and densification: same as Step 4 of Example 1.

[0057] 5. Steam drawing and heat setting: same as Step 5 of Example 1.

[0058] 6. Secondary oiling and re-drying of oil agent: same as Step 6 of Example 1.

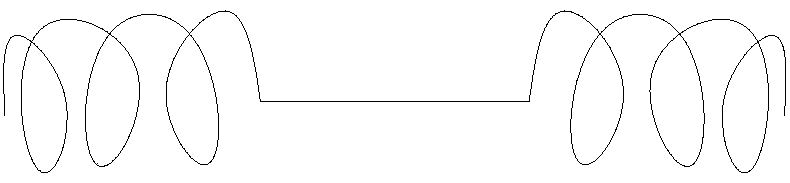

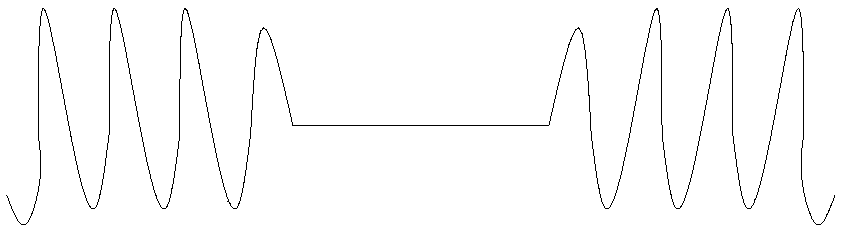

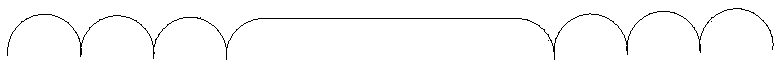

[0059] 7. Fiber steam chopping: the fibers obtained in step 6 are placed in a steam chopping machine, and the fibers are crimped and cut under a steam pressure of 0.7 MPa combined with mechanical action; the crimp density at both ends of the obtained fibers is 0.6 pieces / mm, The equal length of the crimps at both ends is 2 mm, the crimps at both ends are S-shaped, the length of the chopped fibers is 6 mm, and the linear density of the fibers is 1.5 dtex.

[0060] The tensile strength of the obtained chopped fibers in cement mortar was t...

Embodiment 3

[0062] 1. Stock solution preparation: same as Step 1 of Example 1.

[0063] 2. Solidification molding: same as step 2 of embodiment 1.

[0064] 3. Drawing and washing: same as Step 3 of Example 1.

[0065] 4. One-time oiling and drying and densification: same as Step 4 of Example 1.

[0066] 5. Steam drawing and heat setting: same as Step 5 of Example 1.

[0067] 6. Secondary oiling and re-drying of oil agent: same as Step 6 of Example 1.

[0068] 7. Fiber steam chopping: the fibers obtained in step 6 are placed in a steam chopping machine, and the fibers are crimped and cut under a steam pressure of 0.7 MPa combined with mechanical action; the crimp density at both ends of the obtained fibers is 0.6 pieces / mm, The curled length at both ends is equal to 2 mm, the curled shape at both ends is hook-shaped, the length of the chopped fiber is 6 mm, and the linear density of the fiber is 1.5 dtex.

[0069] The tensile strength of the obtained chopped fibers in cement mortar was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com