Split impeller for large single-shell slurry pump

A single-shell, slurry pump technology, which is applied to the components, pumps, and pump components of pumping devices for elastic fluids, which can solve engineering costs and maintenance waste, limited corrosion resistance, and harsh operating conditions. and other problems, to achieve excellent mechanical properties, good exhaust effect, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

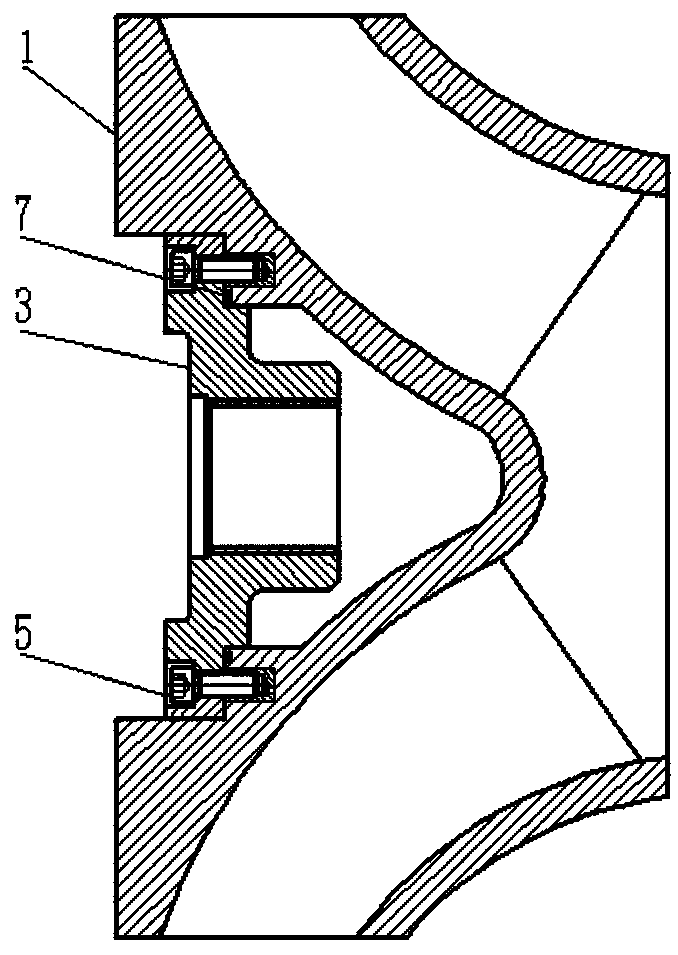

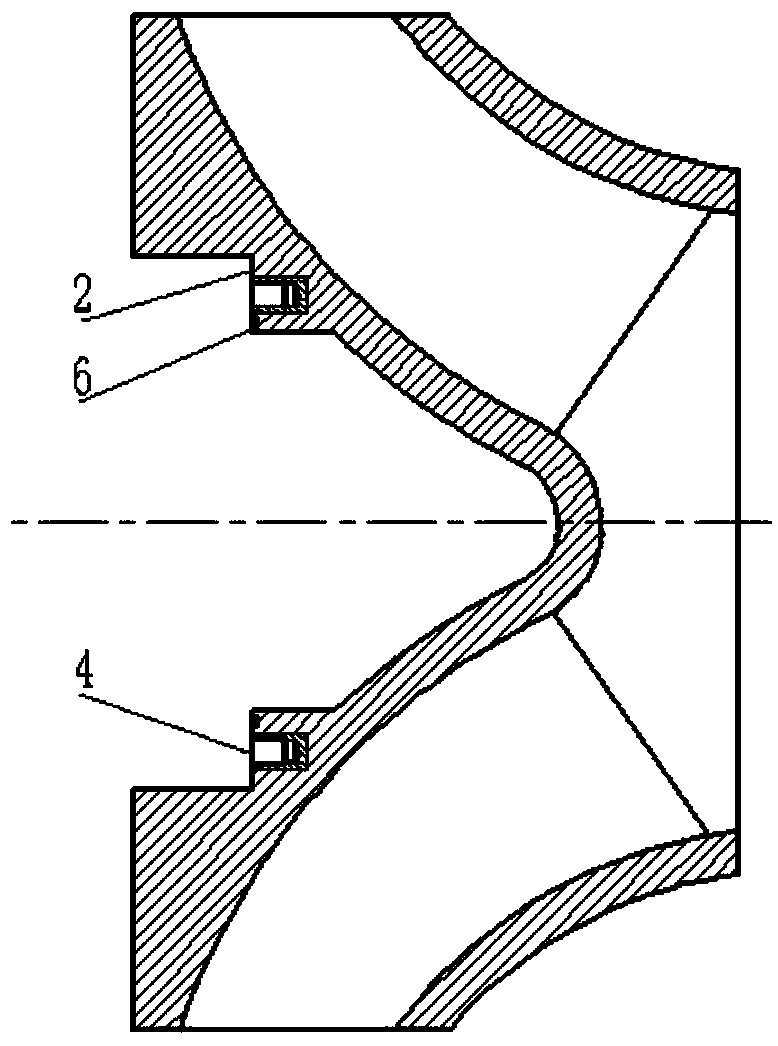

[0041] Such as figure 1 and figure 2 As shown, a split impeller for a large single-case slurry pump includes an impeller body 1, and one end surface of the impeller body 1 close to the pump shaft is provided with a positioning table 2 for positioning and matching with the impeller hub 3, and the impeller hub The disk 3 is embedded in the positioning table 2 and connected and fixed via the connecting piece 5 .

[0042] At present, domestic large-scale slurry pumps are mainly imported according to resistance. Imported slurry pump products are not only expensive, but also have a long lead time for accessories, which often delays production. Therefore, research and development of large-scale slurry pump products can improve wear resistance and corrosion resistance, and run stably Slurry pump products with low maintenance costs play a positive role in promoting energy conservation and emission reduction, resource protection and ecological environment protection in my country. The...

Embodiment 2

[0057] The content of this example is basically the same as that of Example 1, and the similarities will not be repeated. The difference is that the coating slurry includes the following components: 20-35 kg of polyvinylpyrrolidone, 42-54 kg of nanoparticles, High temperature adhesive 30~35kg, surfactant 3~8kg, dispersant 1~2kg,

[0058] The high temperature adhesive is Na 2 O.3.1 SiO 2 Mixed thick colloidal solution with 10-25% epoxy acrylate;

[0059] Surfactant is fatty alcohol polyoxyethylene-3 ether;

[0060] The dispersant is calcium lignosulfonate;

[0061] The nanoparticles include: nano-Al accounting for 30-45% by weight of the nanoparticles 2 o 3 , 50-60% nano-TiC, 10-26% nano-SiO 2 ;

[0062] The coating slurry is prepared through the following steps: put polyvinylpyrrolidone, nanoparticles, dispersant, high-temperature adhesive and surfactant into the disperser to disperse at a line speed faster than 16m / s, and the dispersion time is 20 ~30 minutes, the tem...

Embodiment 3

[0064] As shown in the figure, the structure of this embodiment is basically the same as that of Embodiment 2, and the similarities will not be repeated. The difference is: (4) The quenching and tempering process is adopted, and the heating rate is controlled at 32-35 °C / h, in the temperature range of 600-650°C, step-wise heat preservation for 1-2 hours, quenching temperature of 900-1100°C, heat preservation time of 1-3 hours; tempering temperature of 750°C, heat preservation time of 3-5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com