Cultivation culture medium, preparation method and factoryized strain bag cultivation method of phlebopus portentosus

A cultivation method and a culture medium technology, which are applied in the field of industrialized bacterial bag cultivation and cultivation medium of Dictyostelium bruceae, can solve the problems of high pollution rate, long covering time, and slow growth of boletus mycelium and other issues to achieve the effect of reducing pollution rate and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

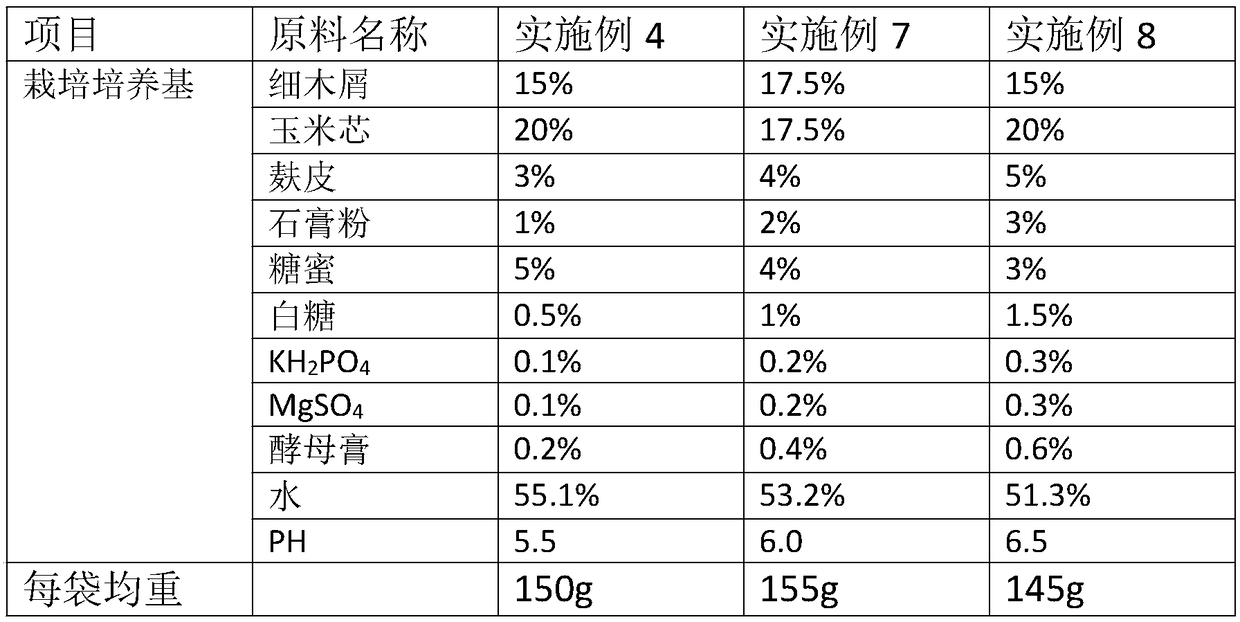

Embodiment 1

[0037] A culture medium, comprising raw materials and the mass percentage of raw materials: 15% fine wood chips, 15% corncobs, 3% bran, 1% gypsum powder, 3% molasses, 0.5% white sugar, KH 2 PO 4 0.1%, MgSO 4 0.1%, yeast extract 0.2%, balance water, pH 5.5.

[0038] A kind of method of utilizing the culture medium to carry out the factory-made bacteria bag cultivation method of reticulum phalaenopsis boletus, comprises the following steps:

[0039] (1) preparing the cultivation medium;

[0040] (2) Cultivation medium bagging and sterilization: the cultivation medium prepared in step (1) is sub-packed in bacteria bags, and then sterilized after sealing;

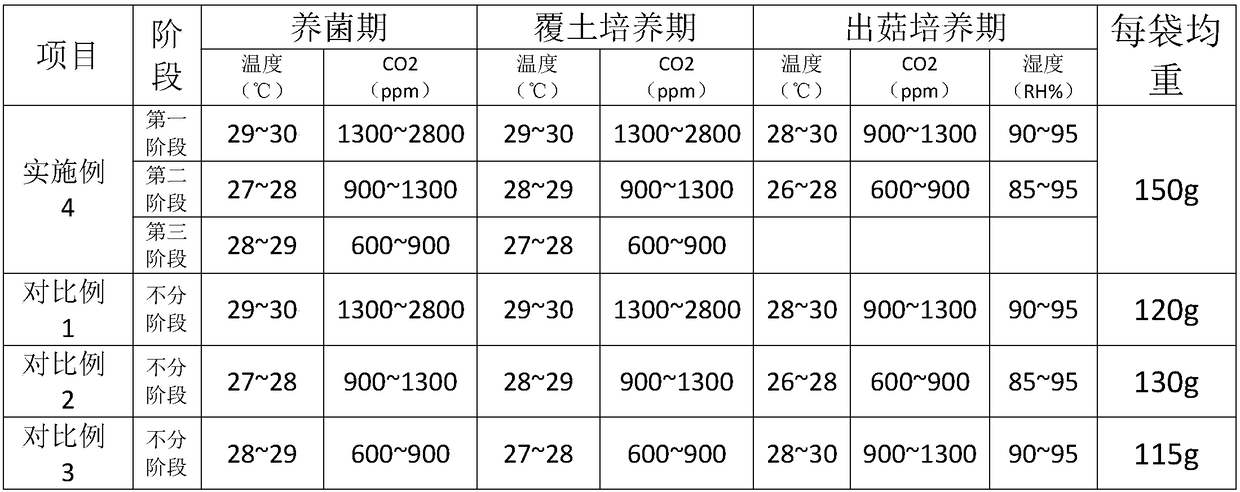

[0041] (3) Inoculation and bacteria cultivation: inoculate the liquid strains cultivated in the fermenter into the cultivated bacteria bags sterilized in step (2), and insert 30-50 ml of strains into each bag, and then carry out stage-by-stage cultivation. Bacterial culture:

[0042] (4) Covering soil, covering soil cultiva...

Embodiment 2

[0045] Compared with Example 1, the difference is that the composition ratio of the cultivation medium is different: bagasse 20%, corn cob 20%, bran 5%, gypsum powder 3%, molasses 5%, white sugar 1.5%, KH 2 PO 4 0.3%, MgSO 4 0.3%, yeast extract 0.6%, the balance is water, pH6.5.

Embodiment 3

[0047] Compared with Example 1, the difference is that the composition ratio of the cultivation medium is different: fine sawdust and straw 17%, corn cob 17%, bran 4%, gypsum powder 2%, molasses 4%, white sugar 1%, KH 2 PO 4 0.2%, MgSO 4 0.2%, yeast extract 0.5%, the balance is water, PH6.

[0048] The moisture content of the soil-containing medium cannot be higher than 51%, otherwise there will be mud, which will affect the ventilation and high viscosity will cause trouble for mechanized charging. The cultivation medium provided by the invention not only has sufficient nutrition and is easy to absorb, but also solves some problems of low water content of the substrate and actual mechanized loading. In addition, the water content of the culture medium is easy to control accurately, and the consistency between batches is good, so it is suitable for industrial cultivation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com