ZIF-8 derived carbon-based material supporting CdS photocatalyst as well as preparation method and application thereof

A ZIF-8, carbon-based material technology, applied in the field of photocatalytic materials, can solve the problems of difficulty in maintaining the pore structure of the precursor, unsuitable for large-scale industrial production, poor crystal form of the ZIF-8 template, etc., and achieve a rich pore structure. Features, high specific surface area, highly dispersed load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

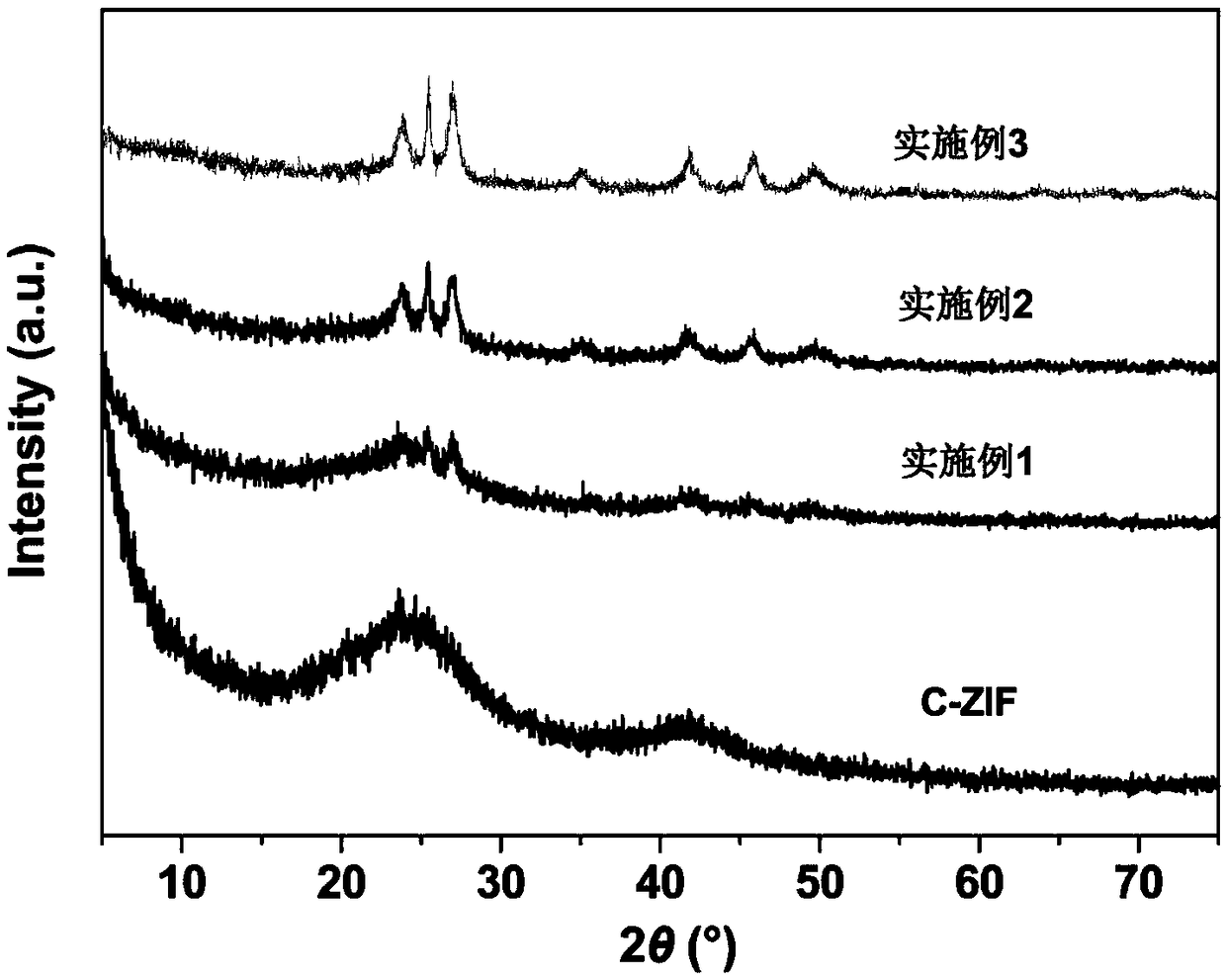

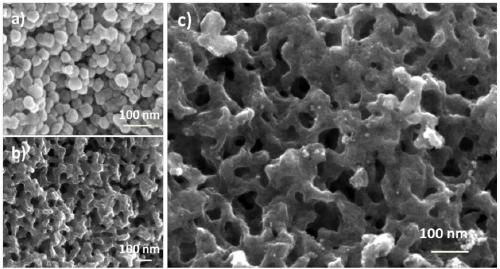

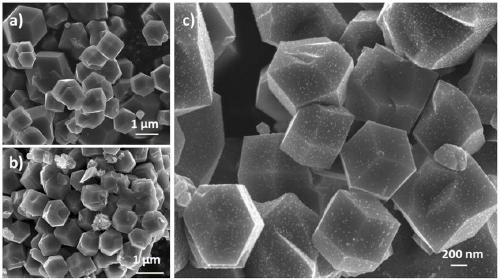

[0031] Mix and dissolve 0.74g zinc nitrate, 0.8g sodium formate and 0.8g 2-methylimidazole in 100mL methanol, stir magnetically for 0.5h, then let stand at room temperature for 12h, then centrifuge, wash, and vacuum dry to obtain ZIF-8; Under protective conditions, the temperature was raised to 1000°C at a rate of 10°C / min by high-temperature carbonization and kept for 3 hours, and then naturally cooled to room temperature to prepare the porous carbon material C-ZIF; then take 0.1g of the prepared porous carbon material C-ZIF -ZIF was dispersed in 0.5mL 3-aminopropyltrimethoxysilane, stirred gently at 50°C for 6h, washed and dried to obtain an amino-modified porous carbon material C-ZIF; the prepared amino-modified The porous carbon material C-ZIF was uniformly dispersed in deionized water by ultrasonic, adding 0.1g cadmium chloride and 0.1g thioacetamide, stirred for 3h, centrifuged, washed, and vacuum-dried to obtain the ZIF-8 derived carbon-based material Photocatalysts loa...

Embodiment 2

[0033] Mix 1.5g of zinc nitrate, 3.1g of sodium formate and 1.5g of 2-methylimidazole in 160mL of methanol, stir magnetically for 1 hour, then let it stand at room temperature for 24 hours, then centrifuge, wash and vacuum dry to obtain ZIF-8; Under the same conditions, the temperature was raised to 1100°C at a rate of 5°C / min by high-temperature carbonization and kept for 2 hours, and then naturally cooled to room temperature to prepare the porous carbon material C-ZIF; then take 0.5g of the prepared porous carbon material C-ZIF ZIF was dispersed in 4mL 3-aminopropyltrimethoxysilane, stirred gently at 60°C for 8h, washed and dried to obtain the amino-modified porous carbon material C-ZIF; the prepared amino-modified porous carbon The material C-ZIF was uniformly dispersed in deionized water by ultrasonic, adding 0.5g cadmium chloride and 0.5g thioacetamide, stirring for 5h, centrifuging, washing, and vacuum drying to prepare ZIF-8 derived carbon-based material loaded with CdS ...

Embodiment 3

[0035] Mix 1.2g of zinc nitrate, 1.8g of sodium formate and 1.8g of 2-methylimidazole in 110mL of methanol, stir magnetically for 2h, then let it stand at room temperature for 20h, then centrifuge, wash, and vacuum dry to obtain ZIF-8; Under the same conditions, the temperature was raised to 950°C at a rate of 8°C / min by high-temperature carbonization and kept for 5h, and then naturally cooled to room temperature to prepare the porous carbon material C-ZIF; then take 0.1g of the prepared porous carbon material C-ZIF ZIF was dispersed in 1mL 3-aminopropyltrimethoxysilane, stirred gently at 70°C for 9h, washed and dried to obtain the amino-modified porous carbon material C-ZIF; the prepared amino-modified porous carbon The material C-ZIF was uniformly dispersed in deionized water by ultrasonic, adding 0.1g cadmium chloride and 0.1g thioacetamide, stirring for 3 hours, centrifuged, washed, and dried in vacuum to prepare ZIF-8 derived carbon-based material loaded with CdS photocat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com