Collapsing intensifier for sodium silicate-bonded sand used for casting

A technology of water glass sand and reinforcing agent, which is applied in casting molding equipment, molds, manufacturing tools, etc., can solve the problems of poor collapsibility and deterioration of sand mold performance, and achieve the effect of improving collapsibility, reducing residual strength and improving collapsibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

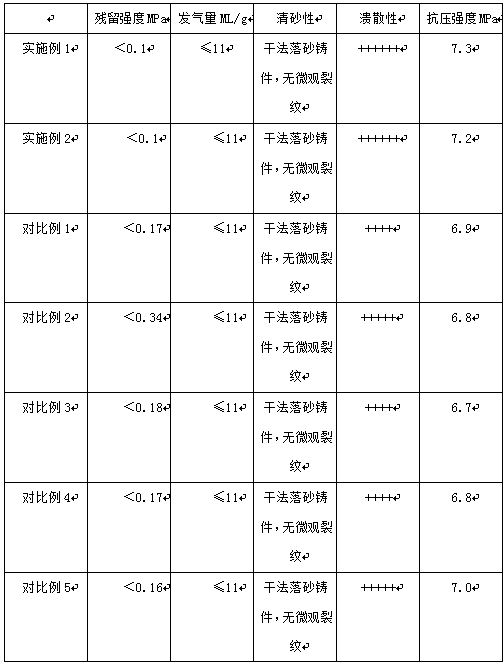

Examples

Embodiment 1

[0020] A water glass sand collapsing enhancer for casting, its raw material components include iron oxide magnetic powder, dickite powder and xanthan gum, in parts by weight, the raw material component of the water glass collapsible enhancer includes 76 parts of iron oxide Magnetic powder, 0.6 parts of xanthan gum and 13 parts of dickite powder.

[0021] Further, the raw material components of the collapsibility enhancer also include ceramic micropowder, fluorosilicate, bentonite and surfactant, in parts by weight, 7 parts of ceramic micropowder, 2.3 parts of fluorosilicate, 2.7 parts of bentonite, 2.5 parts of surfactants.

[0022] Further, the iron oxide magnetic powder is from one or more of white γ-Fe2O3, Fe3O4.

[0023] Further, the surfactant is selected from one or more of organosilicon surfactants, sodium dodecylsulfonate, fluorocarbon surfactants, and hydrocarbon surfactants; the bentonite is sodium bentonite ; The fluorosilicate is one or more of sodium fluorosilic...

Embodiment 2

[0026] A water glass sand collapsing enhancer for casting, its raw material components include iron oxide magnetic powder, dickite powder and xanthan gum, in parts by weight, the raw material component of the water glass collapsible enhancer includes 74 parts of iron oxide Magnetic powder, 0.6 parts of xanthan gum and 13 parts of dickite powder.

[0027] Further, the raw material components of the collapsibility enhancer also include ceramic micropowder, fluorosilicate, bentonite and surfactant, in parts by weight, 7 parts of ceramic micropowder, 0.5-2.3 parts of fluorosilicate, 2.5 parts of bentonite Parts, 2.6 parts of surfactants.

[0028] Further, the iron oxide magnetic powder is from one or more of white γ-Fe2O3, Fe3O4.

[0029] Further, the surfactant is selected from one or more of organosilicon surfactants, sodium dodecylsulfonate, fluorocarbon surfactants, and hydrocarbon surfactants; the bentonite is sodium bentonite ; The fluorosilicate is one or more of sodium f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com