Feed for metal-powder injection molding and preparation method of feed

An injection molding, metal powder technology, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as easy deformation and inability to apply in large quantities, achieve the effect of improving hardness, expanding the scope of market application, and solving easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

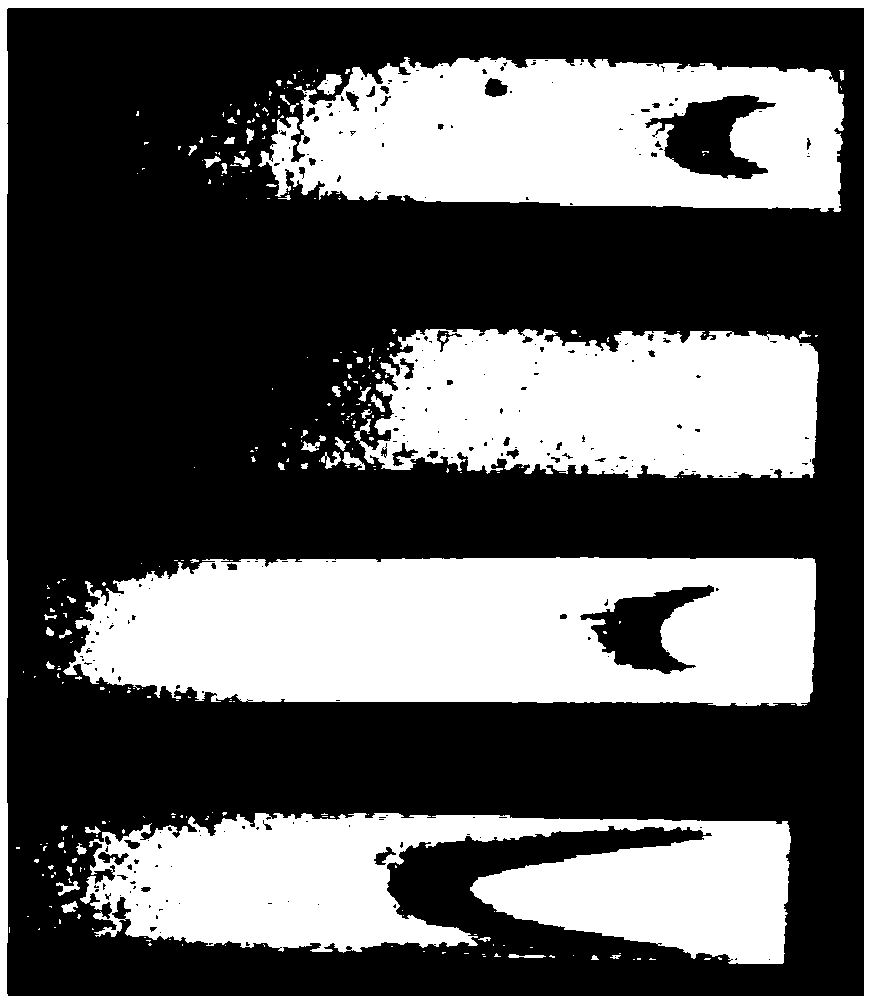

Image

Examples

preparation example Construction

[0050] In one embodiment, a kind of preparation method of described metal powder injection molding feedstock, comprises the following steps:

[0051] S1. adding the stainless steel feed powder to the mixer for preheating;

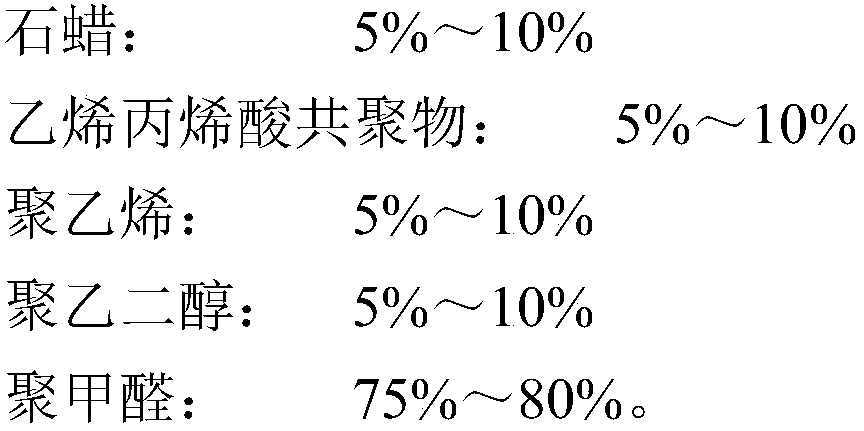

[0052] S2. The forming agent added according to the proportion is mixed;

[0053] S3. Extrusion granulation.

[0054] In a preferred embodiment, in step S1, the stainless steel feed powder is preheated to a predetermined temperature to remove moisture in the powder, more preferably, heated to a predetermined temperature of 200°C.

[0055] In a preferred embodiment, in step S2, the forming agent is added and kneaded at a temperature higher than 170°C.

[0056] In a preferred embodiment, in step S2, the temperature is kept at 185° C., the rotation speed is 20 r / min, the heating is stopped after kneading for 30 min, and kneading is continued for another 30 min.

[0057] In one embodiment, a method of using the metal powder injection molding feedstock to mak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com