ZnCo2O4/ZnO heterostructure composite gas-sensitive material and preparation method

A technology of gas-sensitive materials and heterogeneous structures, applied in the direction of analysis materials, material resistance, chemical instruments and methods, etc., can solve problems that have not been reported, and achieve broad application prospects and good sensitivity characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

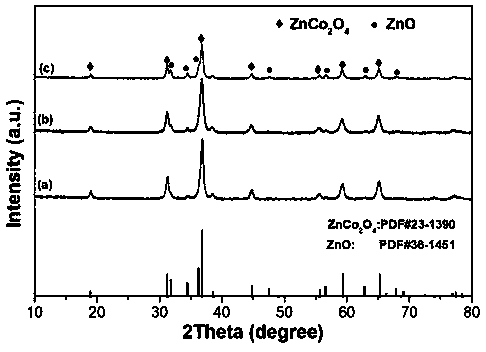

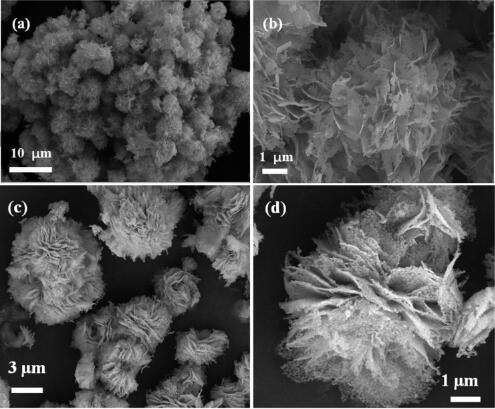

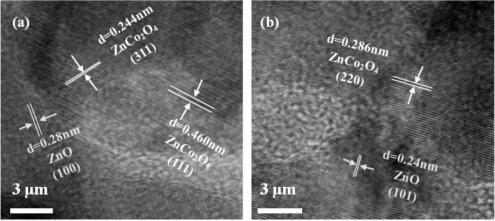

[0024] Under electromagnetic stirring, 10 mL of NH with a concentration of 0.38 mol / L 4 HCO 3 The aqueous solution was slowly dropped into the solution containing 0.72 gZn(CH 3 COO) 2 2H 2 O and 1.5 gCo(CH 3 COO) 2 4H 2 O in 30 mL aqueous solution, after the dropwise addition, continue electromagnetic stirring for 10 minutes to prepare the precursor solution; transfer the obtained precursor solution to a 50 mL polytetrafluoroethylene-lined stainless steel autoclave, which is then sealed and heated at 180 °C Keep it warm for 24 hours, cool to room temperature naturally, collect the product by centrifugation, wash the product four times with deionized water and absolute ethanol, and dry at 60°C for 12 hours to obtain a sacrificial template; the sacrificial template prepared in step 2 The template was used as a self-sacrificing template, and the temperature was raised to 500 °C in air at a heating rate of 2 °C / min, and annealed for 2 hours to obtain ZnCo 2 o 4 / ZnO hetero...

Embodiment 2

[0026] Under electromagnetic stirring, 10 mL of NH with a concentration of 0.38 mol / L 4 HCO 3 The aqueous solution was slowly dropped into the solution containing 0.78 gZn(CH 3 COO) 2 2H 2 O and 1.5 gCo(CH 3 COO) 2 4H 2 O in 30 mL aqueous solution, after the dropwise addition, continue electromagnetic stirring for 20 minutes to prepare the precursor solution; transfer the obtained precursor solution to a 50 mL polytetrafluoroethylene-lined stainless steel autoclave, then seal it and store it at 180 °C Keep it warm for 24 hours, cool to room temperature naturally, collect the product by centrifugation, wash the product four times with deionized water and absolute ethanol, and dry at 60°C for 12 hours to obtain a sacrificial template; the sacrificial template prepared in step 2 The template was used as a self-sacrificing template, and the temperature was raised to 500 °C in air at a heating rate of 2 °C / min, and annealed for 2 hours to obtain ZnCo 2 o 4 / ZnO heterostruct...

Embodiment 3

[0032] Under electromagnetic stirring, 10 mL of NH with a concentration of 0.38 mol / L 4 HCO 3 The aqueous solution was slowly dropped into the solution containing 1gZn(CH 3 COO) 2 2H 2 O and 1.5 gCo(CH 3 COO) 2 4H 2 O in 30 mL aqueous solution, after the dropwise addition, continue electromagnetic stirring for 15 minutes to prepare the precursor solution; transfer the obtained precursor solution to a 50 mL polytetrafluoroethylene-lined stainless steel autoclave, then seal it and store it at 190 °C Insulated for 20 hours under high temperature, after naturally cooling to room temperature, the product was collected by centrifugation, washed with deionized water and absolute ethanol four times, and dried at 70°C for 18 hours to obtain a sacrificial template; the sacrificial template prepared in step 2 The template was used as a self-sacrificing template, and the temperature was raised to 550 °C in air at a heating rate of 3 °C / min, and annealed for 2 hours to obtain ZnCo 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com