Method for detecting EDTA (ethylene diamine tetraacetic acid) in laundry detergent

A detection method and technology for laundry detergent, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as environmental hazards, and achieve the effect of improving recovery rate, good application potential and prospects, and achieving maximization and optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

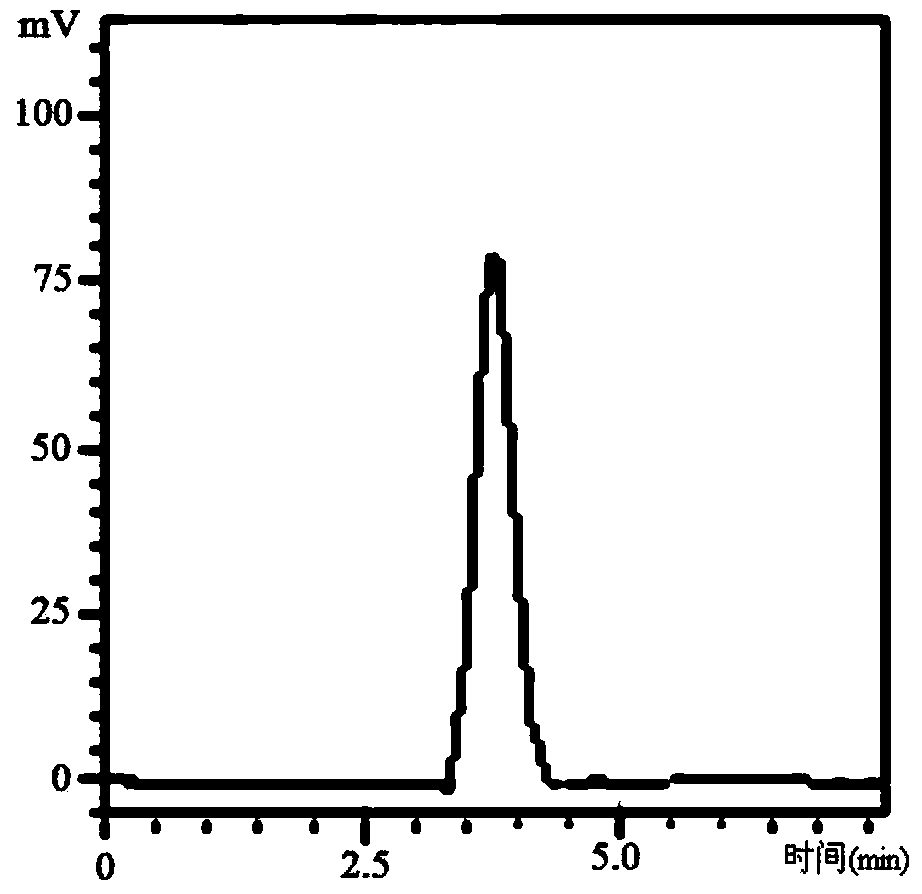

Image

Examples

Embodiment 1

[0052] (1) Get 25ml of potassium bicarbonate aqueous solution of 0.03mol / L, add deionized water to 50ml, and adjust pH to be 5, thereby obtain potassium bicarbonate aqueous solution;

[0053] (2) Add the simulated laundry liquid sample to be determined (wherein the content of EDTA is 10ng / g) into the potassium bicarbonate aqueous solution, the volume ratio of the laundry liquid to the potassium bicarbonate aqueous solution is 1:3, and then Stir at high temperature for 15 minutes, filter while hot, and naturally cool to room temperature to obtain a pretreatment solution;

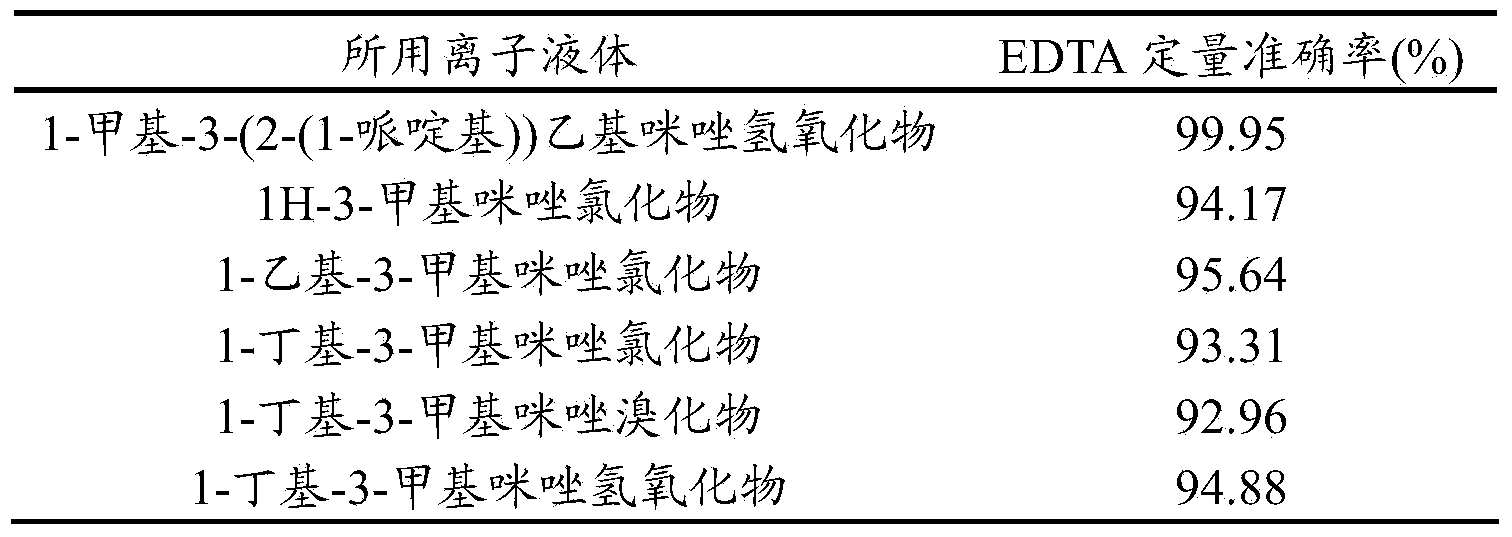

[0054] (3) Add the ionic liquids shown in the following table 1 to the pretreatment liquid obtained above, the volume ratio of the pretreatment liquid to the added ionic liquid is 1:2, shake and extract at 30°C for 15 minutes, and then Centrifuge, discard the aqueous phase, and obtain the ionic liquid phase;

[0055] (4) Add FeCl to the ionic liquid phase obtained above 3 (Its mass volume ratio with ionic l...

Embodiment 2

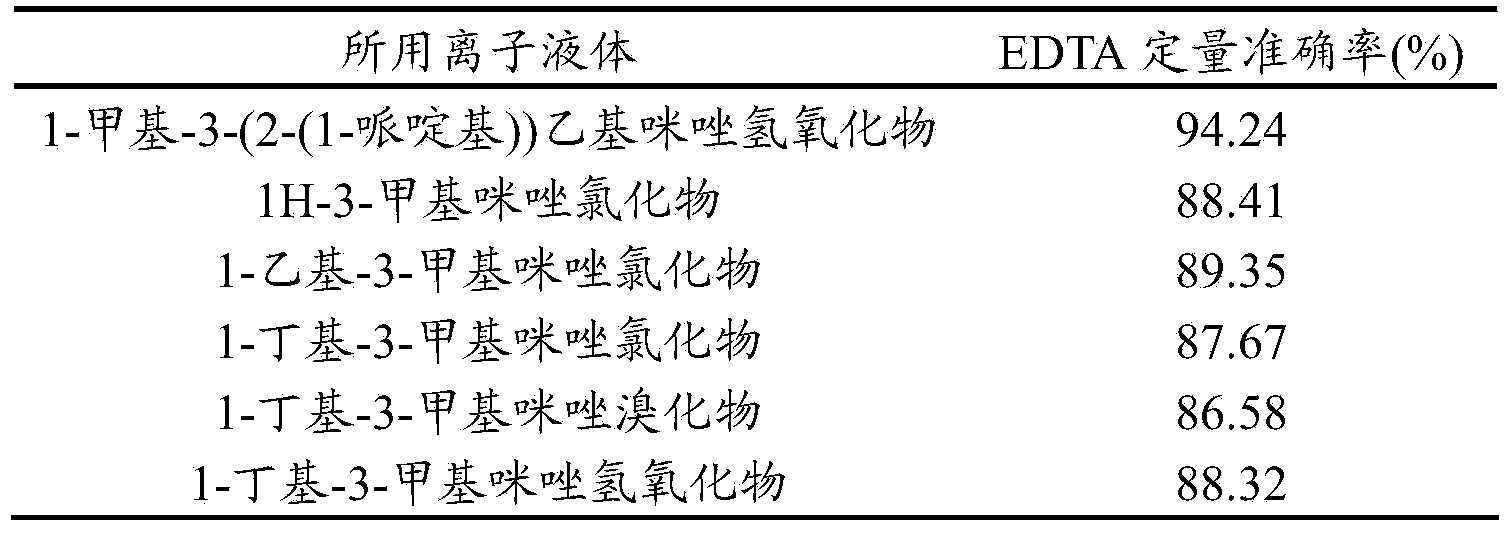

[0063] (1) Add the simulated laundry liquid sample I to be determined (the content of EDTA is 10ng / g) into water, the volume ratio of laundry liquid to water is 1:3, then stir at 45°C for 15 minutes, and Naturally cool to room temperature after filtering to obtain the pretreatment liquid;

[0064] (2) Add the ionic liquids shown in the above table 1 to the pretreatment liquid obtained above, the volume ratio of the pretreatment liquid to the added ionic liquid is 1:2, shake and extract at 30 ° C for 15 minutes, and then Centrifuge, discard the aqueous phase, and obtain the ionic liquid phase;

[0065] (3) Add FeCl to the ionic liquid phase obtained above 3 (Its mass volume ratio with ionic liquid phase is 1:45g / ml), after fully mixing, go up gel column chromatography Superose12 column chromatography and separate, wash with normal hexane earlier (the flushing flow rate of described normal hexane is every 5 times the column volume per hour), the washing time is 25 minutes, and...

Embodiment 3

[0074] (1) Get 25ml of potassium bicarbonate aqueous solution of 0.03mol / L, add deionized water to 50ml, and adjust pH to be 5, thereby obtain potassium bicarbonate aqueous solution;

[0075] (2) The simulated laundry liquid sample I to be measured (wherein the content of EDTA is 10ng / g) is added in the described potassium bicarbonate aqueous solution, and the volume ratio of laundry liquid and potassium bicarbonate aqueous solution is 1:3, then at 45 Stir at ℃ for 15 minutes, filter while hot and cool to room temperature naturally to obtain the pretreatment solution;

[0076] (3) Add FeCl to the pretreatment solution obtained above 3 (Its mass volume ratio with pretreatment liquid is 1:22.5g / ml), after fully mixing, upper gel column chromatography Superose12 column chromatography separates, flushes with normal hexane earlier (the flushing flow rate of described normal hexane is 5 times of column volume per hour), the washing time is 25 minutes, then carry out gradient elutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com