Composite flocculant for quick treatment of coke quenching wastewater and use method thereof

A coagulant and wastewater technology, which is applied in water/sewage treatment, natural water treatment, neutralized water/sewage treatment, etc. It can solve the problems of high system operation risk, high toxicity and long processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

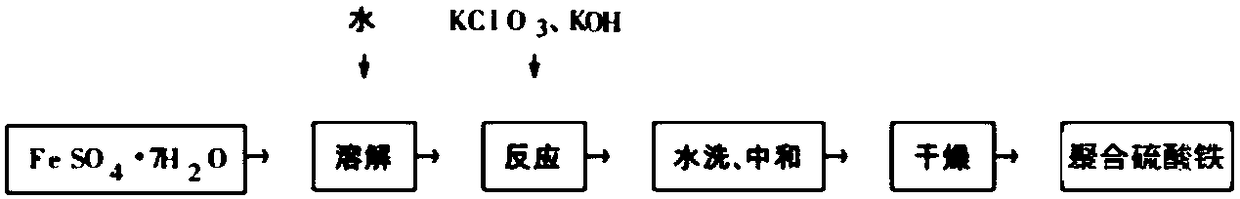

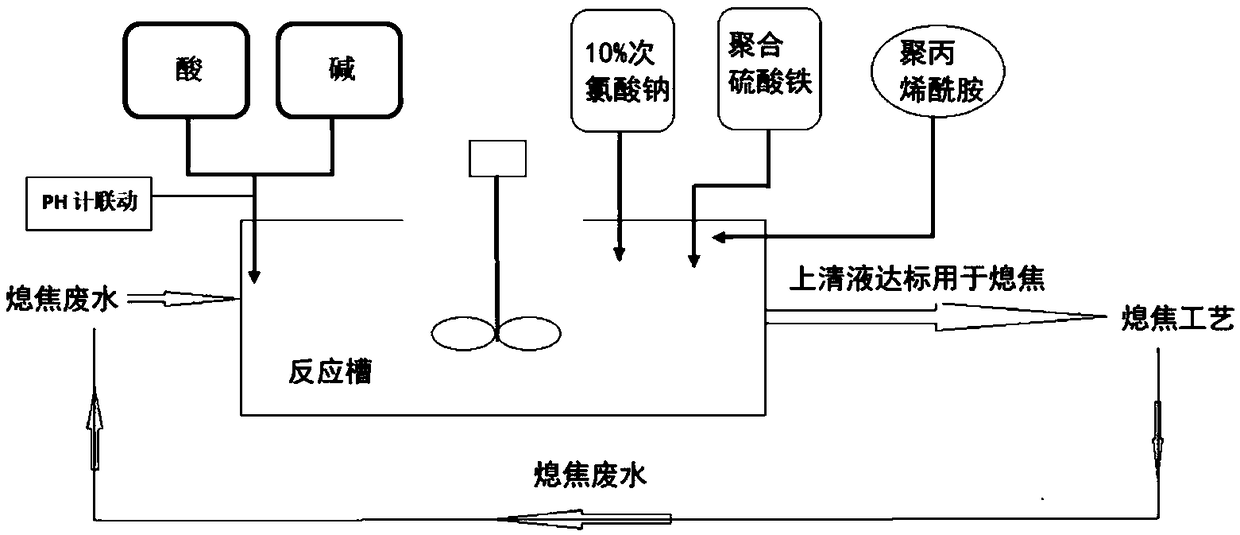

Method used

Image

Examples

Embodiment 1

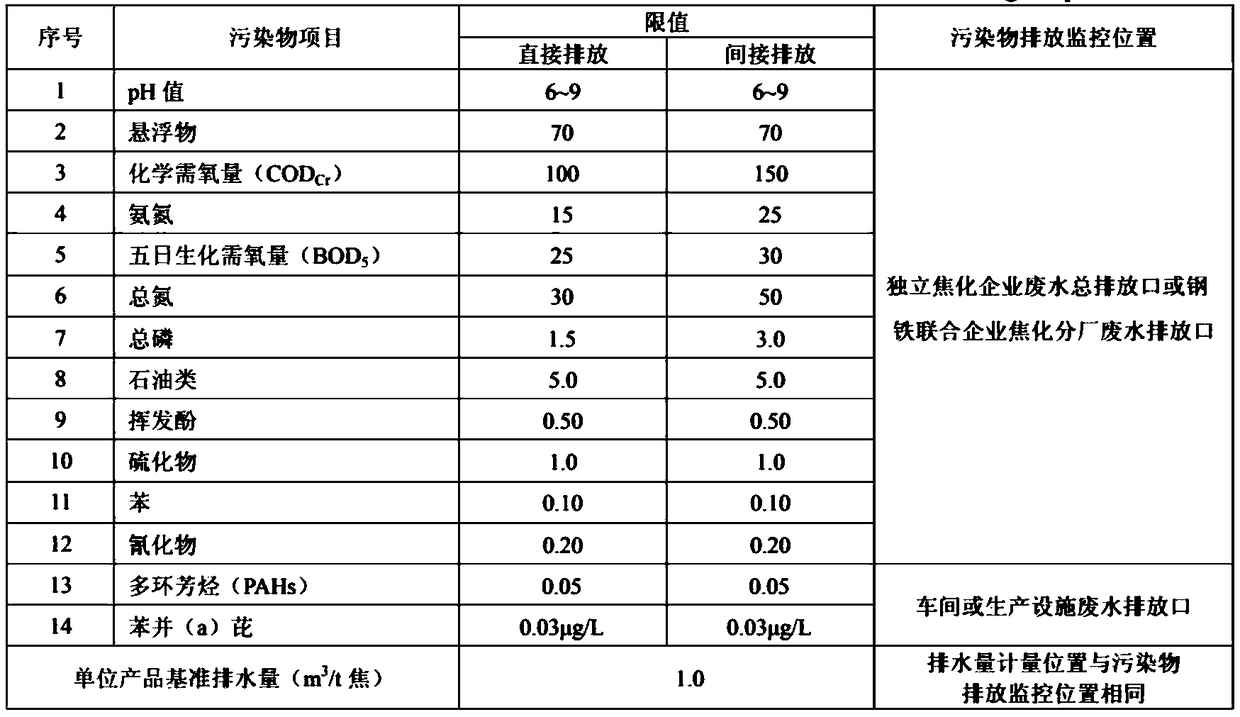

[0025] The waste water from the quenching tank of a coking plant in Shandong has a pH of 7.18, and the volume of water entering the reaction tank with stirring is 1m3. The pH meter in the reaction tank is linked to adding alkali. After adjusting to pH 8.0, the wastewater concentration of the quenching tank is medium (CODcr is close to 500mg / l), so the total amount of coagulant is added according to 2 thousandths of the water volume, so the oxidant is added to contain 10% 1.67L of available chlorine sodium hypochlorite solution, 0.34L of 10% polymeric ferric sulfate solution, 1L of 1‰ polyacrylamide solution, and reaction for 30 minutes. The measurement data of the supernatant is shown in the table below.

[0026] Test Data

Embodiment 2

[0028] The wastewater from the quenching tank of a coking plant in Xuzhou has a pH of 7.8, and the amount of water entering the stirred reaction tank is 2m3. The pH meter in the reaction tank is linked with alkali and adjusted to pH 8.3. Since the wastewater concentration of the quenching tank is higher (CODcr is higher than 500mg / l), the total amount of coagulant is added according to 3 parts per thousand of the water, so the oxidant is added 5L / h of sodium hypochlorite solution containing 10% of available chlorine, 1L of 10% polyferric sulfate solution, 2L of 1‰ polyacrylamide solution, and reaction for 50 minutes. The measurement data of the supernatant is shown in the table below.

[0029] Test Data

Embodiment 3

[0031] The coking wastewater of the coke oven supporting system of a branch of Shanxi Iron and Steel Group needs to be treated for greening. The water volume is 140 tons / hour. The three coagulation sedimentation tanks after the secondary sedimentation tank are used as three reaction tanks, and the effluent of the secondary sedimentation tank is ph7. 5. Adjust the pH of the three reaction tanks to 8.0. Since the concentration of the coking wastewater is low, the total amount of coagulant is added according to 1 / 1000 of the water volume.

[0032] The reaction tank 1 is based on the catalyst: oxidant ratio of 1:5, that is, 2.8 tons / day of sodium hypochlorite solution containing 10% of available chlorine in the oxidizer, 560kg / day of 10% polymeric ferric sulfate solution, and 3.4 of 1‰ polyacrylamide solution are added. Tons / day, the residence time of the reaction tank is 30 minutes.

[0033] Reaction tank 2 is based on the catalyst: oxidant ratio of 1:4, that is, 2.24 tons / day of sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com