Degreasing method for photocuring additive manufacturing precious metal green body

An additive manufacturing and precious metal technology, applied in the field of additive manufacturing, can solve the problems of cracking, deformation, bubbling of green bodies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

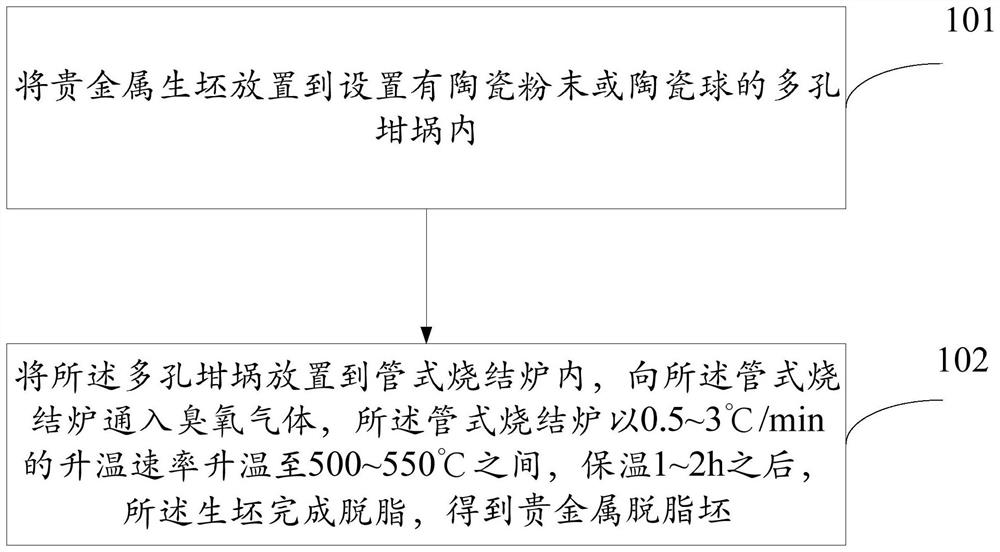

Method used

Image

Examples

Embodiment 1

[0045] A human tooth model made of silver is manufactured based on a light-curing additive manufacturing technology, wherein the light-curing additive manufacturing technology includes the thermal degreasing method of a precious metal green body.

[0046] In this embodiment, the particle size of the silver powder in the silver paste is 20 μm, and the volume ratio of the silver powder in the paste is 6%; the length of the silver powder green body is about 40 mm, and the maximum thickness is about 8 mm.

[0047] Thermal degreasing of tooth-shaped silver green bodies is carried out by the following methods:

[0048] Step 201: completely embed the tooth-shaped silver green body in a porous crucible provided with zirconia balls, wherein the diameter of the zirconia balls is 2mm;

[0049] Step 202: Transfer the porous crucible to a tube-type sintering furnace, feed ozone gas with a concentration of 3 g / h and a flow rate of 1 NL / min into the tube-type sintering furnace, and the tube-...

Embodiment 2

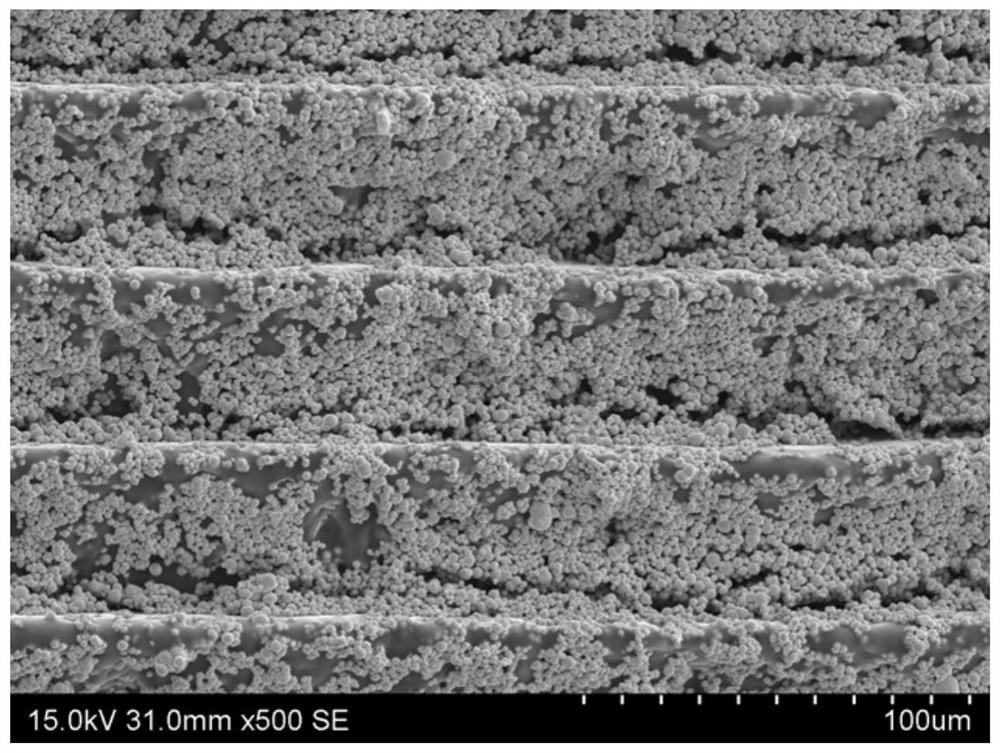

[0053] A sample model of a silver porous structure is manufactured based on a light-curing additive manufacturing technology, wherein the light-curing additive manufacturing technology includes a thermal degreasing method of a precious metal green body.

[0054] In this embodiment, the particle size of the silver powder in the silver paste is 20 μm, and the volume ratio of the silver powder in the paste is 6%. The silver green body with a porous structure has a length of about 25 mm, a width of about 20 mm, a height of about 10 mm, and a porosity of 80%.

[0055] The following method is used to thermally degrease the porous silver green body:

[0056] Step 301: completely embed the silver green body with a porous structure in a porous crucible provided with alumina powder, wherein the particle size of the alumina powder is 80 μm;

[0057] Step 302: Transfer the porous crucible to a tube-type sintering furnace, feed ozone gas with a concentration of 2 g / h and a flow rate of 1 ...

Embodiment 3

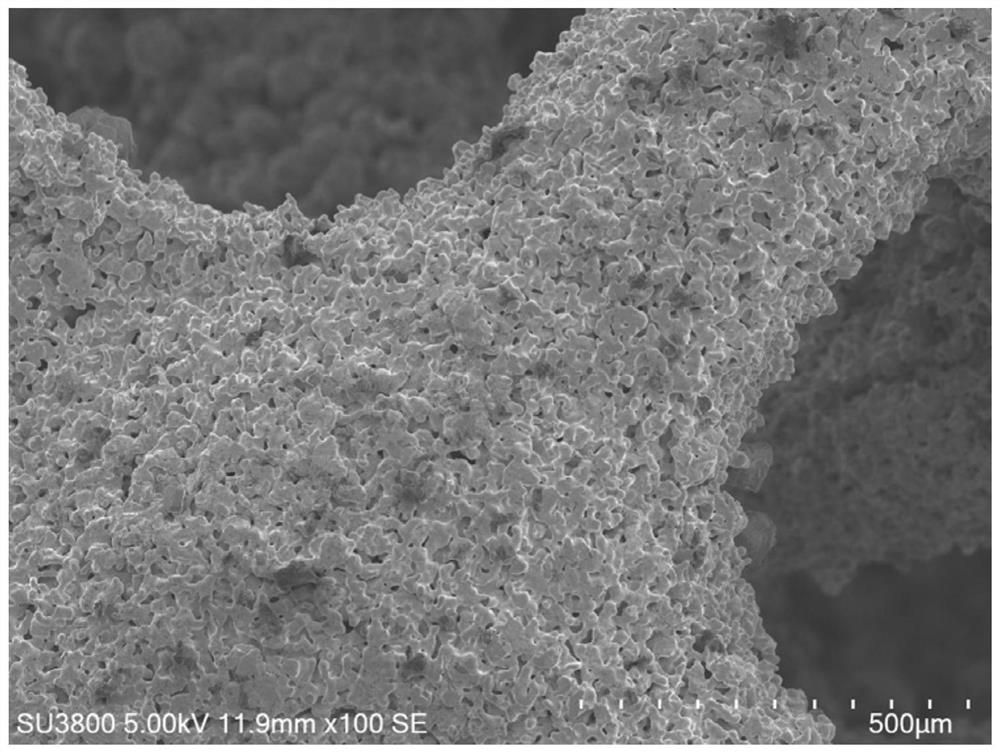

[0061] A porous ring sample model made of silver is manufactured based on light-curing additive manufacturing technology, wherein the light-curing additive manufacturing technology includes thermal degreasing of precious metal green bodies.

[0062] In this embodiment, the particle size of the silver powder in the silver paste is 15 μm, and the volume ratio of the silver powder in the paste is 15%. The diameter of the porous ring-shaped silver green body is about 32mm, the height is about 10mm, and the thickness of the ring body is about 3mm.

[0063] Thermal degreasing of the porous ring-shaped silver green body was performed using the following method:

[0064] Step 401: completely bury the porous ring-shaped silver green body in the porous crucible provided with alumina powder, wherein the particle size of the alumina powder is 100 μm;

[0065] Step 402: Transfer the porous crucible to a tube-type sintering furnace, feed ozone gas with a concentration of 5 g / h and a flow r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com