Method for making artificial fishing reef

A production method and technology of artificial fish reefs, applied in fish farming, manufacturing tools, ceramic products, etc., can solve the problems of low survival rate, long operation time, high investment in manpower, material resources and financial resources, and achieve efficient use of marine resources, preparation The method is simple and easy to implement, and the effect of increasing the biological density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

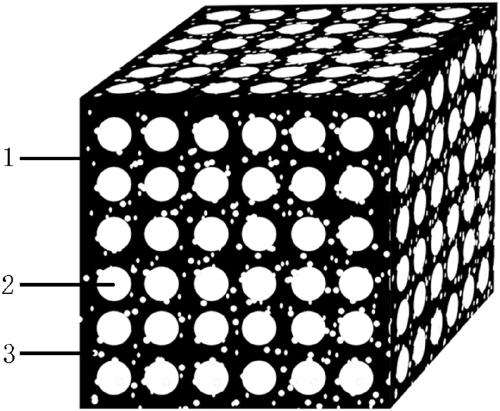

Image

Examples

Embodiment Construction

[0020] The present invention is further described below in conjunction with specific embodiment:

[0021] As an example, the manufacturing method of the artificial fish reef in this embodiment includes the following steps:

[0022] Step 1. The cement is 86% (wt) of ordinary Portland cement with the label of 42.5R, the admixture is 14% (wt) of fly ash, the water-material ratio is 0.43, and the admixtures include water reducers and foam stabilizers , its dosage accounts for 1.48% (wt) and 0.013% (wt) of the cement cementitious material quality respectively, and the chemical blowing agent adopts hydrogen peroxide, and its dosage accounts for 7% (wt) of the cement cementitious material quality, the above-mentioned Cement, admixtures, admixtures, and water are mixed and stirred at a high speed until uniform, and the stirring time is controlled at 4min-5min; then the above-mentioned chemical foaming agent is added to the slurry to continue stirring, and the stirring time is preferab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com