Double-component water-based binder and preparation method thereof

A water-based adhesive, two-component technology, used in adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of poor mechanical properties, low bonding strength, etc., and achieve high bonding strength. , high solids content, enhanced Coulomb force and hydrogen bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

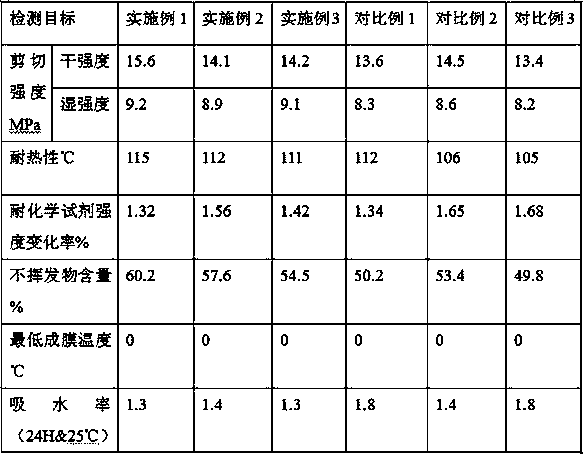

Examples

preparation example Construction

[0029] A preparation method of a two-component water-based binder, comprising the steps of:

[0030]S1. Take montmorillonite and mix it with distilled water at a mass ratio of 1~3:15~20, then add octadecyltrimethylammonium chloride with 30~40% of the mass of montmorillonite, and stir and mix at 75~80°C for 3 ~4h, suction filtration, take the suction filter residue and wash it with deionized water for 3~5 times to get the washings, take the washings and add sorbitol according to the mass ratio of 10~15:2~5, ultrasonically oscillate for 4~5h, then add the washings Component A of the water-based binder with 8~10 times the mass is stirred and mixed at 65~70°C for 20~30min, then heated to 115~125°C, kept at a vacuum of -0.06MPa for 30~40min, cooled to 65~75 ℃, to get cooling material;

[0031] S2. Take the cooling material and add absolute ethanol according to the mass ratio of 50~60:13~20, stir and mix for 20~30min to obtain the mixture, take the mixture and add the water-based b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com